Cetirizine Oral Solution Manufacturing: The Complete FAQ Guide In 2025

Are you curious about the manufacturing of cetirizine oral solution? Do you know cetirizine oral solution manufacturing constitutes a specialized set of manufacturing protocols?

Manufacturing cetirizine oral solution is not just about mixing ingredients together; it also relies on the effective integration of pharmaceutical know-how, advanced instrumentation, and rigorous testing measures. The journey of this liquid cetirizine from initiation to patients is all about achieving quality and safety through vigilant control of every processing step.

This FAQ guide about “Cetirizine Oral Solution Manufacturing” is designed to educate both pharmaceutical specialists and the general public on the science and artistry involved in the development of this essential medication. Let’s start reading!

1.What is cetirizine oral solution manufacturing?

Cetirizine Oral Solution Manufacturing

It is an industrial-scale process in which a liquid formulation of cetirizine is formed. Cetirizine is an antihistamine drug- widely used around the globe to reliving symptoms of different sorts of allergies, hay fever, itchy eyes (conjunctivitis), runny nose, and hives. It is usually consumed orally and inhibits histamine signaling.

Cetirizine oral solution manufacturing, in fact, encompasses the devising of a stable liquid solution of cetirizine by sourcing high-quality starting materials, their mixing and solubility, agglomerates or impurities filtration, quality assessment, and finally, packaging in leak-proof bottles.

2.How is cetirizine oral solution manufacturing beneficial to manufacturers and consumers?

Like every other industrial manufacturing, cetirizine oral holds a huge promise of lightning-fast processing and delivering filled bottles in record time. Consumers stand to gain significantly with this manufacturing process like quicker relief from discomfort and more. Now, without further ado, let’s look at the remarkable benefits of cetirizine oral solution manufacturing:

Faster Production and Market Demand

Faster Production- Picture Courtesy: Pharma Frenchie

Allergies season usually brings large cases of runny noses, watery eyes, sour throats, itchy ears, and fevers. So, the demand for cetirizine is all-time high this season. But, you as pharmaceutical manufacturers effortlessly meet your orders of cetirizine through a faster processing rate of cetirizine oral solution manufacturing. A large number of automated machines prepare, mix, and pack cetirizine oral solutions in a short time.

Catering To Young and Old Patient Demographics

Catering To Young and Old Patient Demographics- Picture Courtesy: Bova Network

Are you one of those individuals who have a phobia of popping pills? Then cetirizine oral solution manufacturing has got your backside. It develops an oral solution that is effortlessly taken spoonful and saves you from the trouble of swallowing large and bulky pills. This liquid solution is loved and well-accepted by both pediatric and geriatric populations, thus improving patient adherence to the dosage regime.

Swift Onset of Action

Swift Onset of Action- Picture Courtesy: Galaxy Sivtek

While not always the case, liquid medications have a speedier onset of action in contrast to oral solid dosage, for instance, capsules or tablets. Why do you think that is the case? Normally, cetirizine oral solution manufacturing encompasses the dispersion and dissolution of tiny particles of cetirizine in a liquid base, which are instantly absorbed by blood circulation, leading to rapid drug response and relief from symptoms.

Easy to Use and Administer

Easy to Use and Administer- Picture Courtesy: Mytour

Oral cetirizine solution normally comes in premeasured bottles with clear written instructions to tailor treatment approaches for both grownups and kids. Not only this, its packaging includes dosing tools, such as spoons, droppers, or measuring cups, offering users ease in measuring precise dosage and simplifying the administration process.

Value-Priced and Pocket-Friendly Production

Value-Priced Operation- Picture Courtesy: Colorado Springs Gazette

Oral cetirizine solution manufacturing is a trusty champion of pharmaceutical manufacturers, presenting them with a lean and pocket-friendly path to gain a top spot in the competitive market. Because it has relatively a smaller number of operational steps than oral dosage formulation and also does not need top-notch solutions and tools. Hence, proving simplicity is eventual sophistication.

3.What are the primary ingredients and excipients in cetirizine oral solution manufacturing?

The cetirizine oral solution does not have cetirizine but is also formulated with various excipients that work with each other in perfect harmony to deliver the right dose of cetirizine every time. A brief description of primary components and other ingredients are penned below for your information:

Active Ingredient: Cetirizine

Active Ingredient: Cetirizine- Picture Courtesy: PharmaAdda

You’ve guessed it right! In cetirizine oral solution, cetirizine is the main player. It is a primary compound responsible for curing the symptoms of seasonal allergies, allergic asthma, and hay fever, such as sneezing, coughing, tearing, and pink and swollen eyes.

Excipients

Excipients- Picture Courtesy: Ingredients Network

Although they don’t have any therapeutic role, still they are included in cetirizine formulation. They create a picture-perfect symphony with solubility, stability, and taste masking of the formulation. Some important excipients in cetirizine oral solution are stated below:

Preservatives

Preservatives

They act as a sentinel of formulation that bans the microbial invaders from entering inside cetirizine oral solution and retaining its top quality and integrity. Sodium benzoate or methylparaben are regularly employed as preservatives in cetirizine oral solution manufacturing.

Sweeteners

Sweeteners- Picture Courtesy: Healthline

Children shy away from bitter-tasting medication. So, sweeteners, such as sucrose, sorbitol, or sucralose are incorporated during preparation to impart a characteristic sugary flavor to cetirizine oral solution that children often find hard to resist.

Flavorants

Flavorants- Picture Courtesy: FlavorSum

They are natural or artificial additives that alter the perceptual impression of medications by mimicking flavors of natural food sources, for instance, orange, strawberry, grapes, mango, and more. Through artful formulation, they magically transform cetirizine from bitter to better.

Buffers

Buffers- Picture Courtesy: Seneca

Their function is to keep the pH of the cetirizine oral solution in check. With their buffering capacity, they do not allow pH changes thus, playing a role in the effectiveness and agreeable taste of cetirizine.

Solvents

Solvents- Picture Courtesy: BYJU’S

Usually, purified water is the main component, carrying the whole formulation ensemble from cetirizine to sweeteners, buffers, and others. It is a liquid medium in which all solute molecules are dissolved to develop a seamless liquid formulation.

Stabilizers

Stabilizers- Picture Courtesy: My Spice Sage

What role does a stabilizer have in cetirizine oral solution formulation? It’s easy! They are like glue and ensure medication is delivered to patients without a hitch. Yes, they stabilize formulation both physically and chemically by preventing the breakdown of different components.

Thickening Agents

Thickening Agents- Picture Courtesy: Globy

Just like gummies, thickening agents or viscosity agents- for instance, xanthan gum or hydroxyethyl cellulose- are included in the formulation to add a right touch of thickness or viscosity. It allows a smooth pour to every medication drop.

Antioxidants

Antioxidants- Picture Courtesy: Cosmébio

Although oxygen is a life-stimulating agent, it may generate free radicals that can destroy whole cetirizine oral solution. Hence, ascorbic acid or sodium metabisulfite have found their way into the liquid formulation to keep the latter safe from oxidative damage.

4.What operational steps are implicated in the cetirizine oral solution manufacturing?

Precision is key in any pharmaceutical manufacturing. In cetirizine oral solution manufacturing, every step- from preparing ingredients to final packaging- is precisely executed to have an ideal fusion of safe and effective medication. Therefore, let’s learn about each step in cetirizine oral solution manufacturing:

Ingredient Sourcing and Pre-processing

Ingredient Sourcing- Picture Courtesy: klippit

As a preliminary step, you are advised to first thoroughly check and assess the quality of numerous ingredient components before beginning the main processing activity. Then, you cautiously weigh every ingredient and set aside their required amount according to the formulation recipe.

To prepare the solution, you need to add highly sterile water- void of any type of impurity or microbe- in a mixing tank.

Mixing and Complete Uniformity

Mixing and Complete Uniformity- Picture Courtesy: Bulk Solid

This is where the fun begins! First, put cetirizine dihydrochloride in water and slowly stir it. After attaining complete dissolution, add other excipients sequentially. These components are thoroughly blended and distributed in solution with the help of mixers or blenders. Lastly, you should check the pH of the mixture and include a suitable quantity of buffer to stabilize the cetirizine oral solution.

Removing Particulates

Removing Particulates- Picture Courtesy: lagnataekni

It is an integral step as you don’t want any contaminants in your cetirizine oral solution. But how to do that? A fine filter screen or ultra-fine membrane having an aperture size of 0.22-micron filter is best for filtering even the smallest of impurities to attain the gold standard of pharmaceutical purity.

Quality Checking

Quality Checking- Picture Courtesy: Intubio

After filtration, samples are extracted from every product batch to test their different quality parameters. It is a final checkpoint, where products passing the desired threshold of pH, viscosity, flavor, and efficacy are distributed to the next operational step. Final products are also investigated for microbial growth to ensure patient safety.

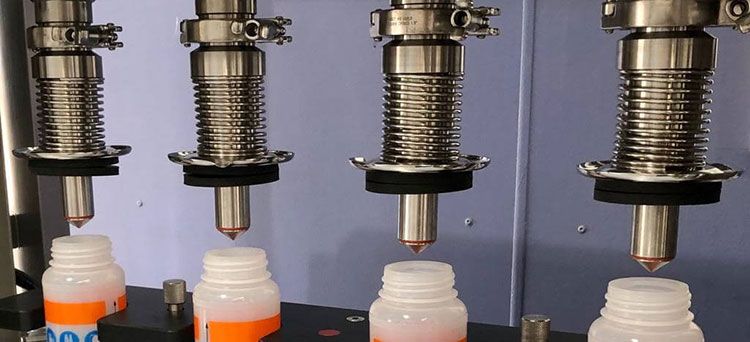

Filling, Capping, and, Labeling

Filling, Capping, and, Labeling- Picture Courtesy: Icon Equipment

The actual packaging stage starts by initially dispensing filtered cetirizine oral solution into pre-sterilized bottles via automated filling systems in a controlled sterile environment. The next step is capping bottles with tamper-proof and leak-proof caps to safeguard inner bottle contents against entry of contaminants and spilling.

Finally, each product bottle is clearly labeled with product usage facts and storage guidelines. It helps in ingredient traceability, product tracking, and right use.

5.What instruments have a role in cetirizine oral solution manufacturing?

Hopefully, you’ve learned about the sequence of steps in cetirizine oral solution manufacturing. Now it's time to have a look at various excellent machines or instruments used in the cetirizine oral solution manufacturing.

Water Sterilization Instruments

AIPAK Engineering Water Sterilization System

It is the very first device in the pharmaceutical creation of a cetirizine oral solution. What’s about its function? It treats potable water to yield pharmaceutical-grade water. This system consists of a multitude of subunits, such as a pretreatment unit, deionization stem, activated carbon system, and reverse osmosis device. They extract tiny bits and pieces of fragments particles, chemical compounds, microorganisms, etc. to disinfect water.

Mixing Devices

AIPAK Cone Mixer

Undeniably! For the cetirizine oral solution manufacturing the beginning step would be mixing. Whether this is solvent-solvent mixing or incorporating solid ingredients in the solution, you will need advanced shear and stirring machines.

For example, agitators, baffles, cone mixers, or impellers. There are various mixing instruments that have either tumbling motion, convective, or diffusive which results in fine and smooth mixtures.

Homogenizers

AIPAK Homogenizer

Apart from mixing instruments, this manufacturing also has homogenizers. They behave as tools for mixing as well as reducing the particle sizes or crushers. And form micro-sized particles to attain a faultless and uniform distribution of the ingredients inside the oral solution. The homogenizer performs its job by producing high pressure shear force that will be capable of mixing small to harsh elements used in a blend.

Solution Filter Systems

Filter System

These devices only allow smaller-sized particles and solvents to pass through the barrier screens, such as membranes, bags, or cartridges. The blended mixture of cetirizine is flooded across the preferred device, which captures and holds undesired particles while permitting the clean mixture to move across it.

Cetirizine Oral Solution Filling Machine

Allpack Cetirizine Oral Solution Filling Machine

The prepared and filtered solution is filled inside the bottles with the help of a filling machine with various filling systems like piston fillers, pump fillers, and pressure fillers that allow zero-dripping technology for dispensing cetirizine oral solution with high exactness without any spilling or product wastage.

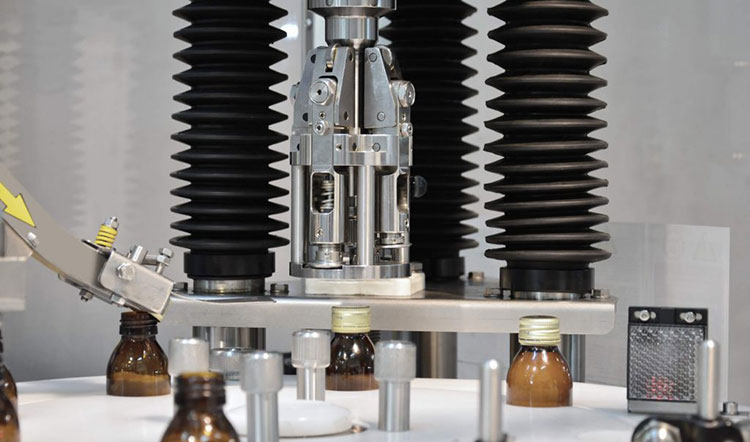

Capping Machine

AIPAK Capping Machine

To keep the solution protected, usually capping or sealing machines are integrated into cetirizine oral solution manufacturing. It ensures that every product is secure and sterile till you open the bottle. They include caps or seals on the cetirizine oral solution bottles to shield packed medication from contamination. This device is essential for placing flawless closure, thus locking the quality and stability of the cetirizine solution.

Labeling Equipment

AIPAK Labelling Equipment

This is absolutely used for improving your brand as well as giving you useful information in the form of label applications over the bottle surface. It applies labels with exact placement on every product bottle to create a well-polished look for display purposes. There are various types of labeling machines such as adhesives, hot glue, wrap around, RFID and so much more. All of them are designed for specific categories of packaging materials.

6.How to differentiate between cetirizine oral solution manufacturing VS regular oral solution manufacturing?

People think that cetirizine oral solution manufacturing is identical to regular oral solution manufacturing. But, in fact, there are a wide array of variances in both these manufacturing types. So, to avoid confusing both of them, read through the next section.

Cetirizine Oral Solution Manufacturing VS Regular Oral Solution Manufacturing- Picture Courtesy: White Steel GmbH

| Attributes | Cetirizine Oral Solution Manufacturing | Regular Oral Solution Manufacturing |

| Inclusion of Active Components | It includes a particular antihistamine, cetirizine dihydrochloride as an active ingredient, which is the benchmark for managing symptoms associated with allergies and hay fever. | In regular oral solution manufacturing, multitudes of active ingredients could be incorporated from vitamins to analgesics, from antiacids to antibiotics. Due to the diverse nature of ingredients, this manufacturing type is carried out for various therapeutic purposes. |

| Excipient Choice | It usually needs various types of excipients for disguising taste, stabilizing medication, preserving its properties, and enhancing its dissolution rate. | The choice of excipients in regular oral solution manufacturing is typically based on the characteristics of active components and the therapeutic effect of the product. |

| Compliance with Regulations | It is regulated by stricter regulatory standards and testing, for example, stability studies, pharmacovigilance, and others because it produces a therapeutic product intended for oral administration. | Its regulatory scrutiny is dependent upon the treatment purpose of the medication. Nutraceutical solutions do not comply with stringent obligations in contrast with pharmaceutical solutions. |

7.How long is the shelf-life you offer after cetirizine oral solution manufacturing?

Shelf-life of cetirizine oral solution- Picture Courtesy: Cristalco

Once you formulate the cetirizine oral solution, it will be stable for approximately two years to three years (24-36 months). This solution is prepared by the addition of certain particular preservatives that makes the formulation quite stable and capable of resisting the microbial growth for a longer time.

Side by side the pH range is also important to offer stability to the solution. This means that when you have pH of the solution around 4.5–5.5 the microbial progression can be controlled and can't be spread. In the last, the solution is filled in a container with a dark bottle. So, it remains stable and prevents photodegradation too. These all things make the extended shelf life of the cetirizine oral solution effectively.

8.How to validate cetirizine oral solution manufacturing?

Process Validation- Picture Courtesy: Corden Pharma

It is important to validate cetirizine oral solution manufacturing as, without it, you would not produce a high-quality product that ticks all the boxes of expectations of customers., this is a key step you should not ignore. By validating this, you will be assured that the entire production is formulated with high quality. So for your assistance, look at the below points to learn more about process validation:

| Design Qualification or DQ | In this process, the design of the facilities and equipment is validated for operation and all required points are complying your production needs and international quality standards. |

| Installation Qualification or IQ | It checks and confirms to their user that whatever the instrument used in the cetirizine oral solution manufacturing have perfect connection, utilities, plugs. This process also confirms you that the installation environment of equipment has a suitable temperature, humidity, and more. |

| Operational Qualification or OQ | It assesses that installed instruments are working according to their given descriptions by the manufacturer. And they are operating within their preset thresholds and tolerances. In this process, the all main functions and capabilities of the equipment are tested and gauged against predefined acceptance. |

| Performance Qualification or PQ | It is the last and critical step, you will be checking the performance of the instrument in the presence of a sales representative person to ensure that it is performing all the tasks correctly as defined by them or not. |

Conclusion

After reading this informative article, I assume that you will be able to understand the science of art behind cetirizine oral solution manufacturing. This is not only the game of ingredients but also the involvement of various machines that are discussed above. So once you get right ingredients and right machines then it wont be impossible to get a great and quality manufacturing. How about investing with AIPAK ENGINEERING to buy machines required for making oral solutions? We offer you excellent series of equipment like manufacturing, filling, and packaging with advanced techniques. Let's open your journey of success with us. For more information, please message our team, you will be get connected with us shortly.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours