Antibiotic Injection for Dogs: The Complete FAQ Guide In 2025

Is your furry canine fighting an infection? Does vet recommend it antibiotic injection and you are concerned about its safety?

Well, don’t worry because millions of dogs suffer from serious bacterial infections every year, thus they need an antibiotic injection for dogs. It is completely safe and with its administration, your pet will get better in no time. However, understanding your dog’s antibiotics is a sign of a good pet owner and it shows that you care for your beloved companion.

If you’re curious about the working of antibiotic injection for dogs, its components, administration, advantages, side effects, and more? Then you’re at the right place. In this guide, we’ll ease your concern by providing thorough and up-to-date knowledge about this medication. Let’s navigate this world together.

1.What is meant by antibiotic injection for dogs?

Antibiotic for dogs- Picture courtesy: Bridge Park Animal Hospital

Like humans, your furry companions also acquire bacterial infections, subsequently needing medications to cure them. And this preparation is antibiotic. Antibiotic injection for dogs is defined as a liquid formulation injected or infused parenterally into the dog.

Since it is a parenteral medication, hence, it is delivered into the dog's body without first swallowing it. It is dispensed either through a muscle, under a skin layer, or into a vein. It goes straight to the bloodstream; therefore, has improved absorption and rapid injection.

2.Why do you use antibiotic injection for dogs?

As you’re aware antibiotic injection for dogs is one of the effective methods for treating bacterial diseases because of their rapid and efficacious treatment. Now, let’s discover some primary reasons why antibiotic injection for dogs is the preferred treatment choice of vets:

Benefits of antibiotic injection for dogs

Swift Action

Swift Action- Picture courtesy: Nature’s recipe

A key factor in favoring antibiotic injection for dogs is its rapid therapeutic response. Vets administer this med into a body cavity, which means that it remains unaltered by the digestive system unlike medications taken by mouth. Consequently, the antibiotics quickly battle bacteria in some cases within a few minutes.

Best for Dogs with Gastric Issues

Best for Dogs with Gastric Issues- Picture courtesy: PetMed

Many dogs can’t tolerate well oral antibacterial due to various gastric-related issues, such as vomiting, diarrhea, suppressed appetite, gastric discomfort, and, problems with absorption from the gut. Therefore, they recommend antibiotic injection for dogs as it doesn’t affect the gut in any way. Moreover, it has 100% precise dosing and a higher absorption rate.

More Convenience

More Convenience- Picture courtesy: Omlet

It is hard to give antibiotic pills to dogs because pets like children don’t want to take them, hence, it often leads to some serious struggle and quite a lot of effort on the owner's part. Subsequently, for convenience purposes, antibiotic injection for dogs is used by vets to deliver antibiotics, which removes the hassle of daily administration. Furthermore, some injections can last up to a fortnight.

Useful in Emergency Situations

Useful in Emergency Situations- Picture courtesy: Stem cell vet

There are various emergency situations, where antibiotic injection for dogs are quite useful. They often act as a first line of defense against post-surgical infections. Moreover, in critical and severe infections, like sepsis, deep skin infection, and bone or joint bacterial diseases, they offer rapid therapeutic response.

Dose Precision

Dose Precision- Picture courtesy: Wellness veterinary

More than often, antibiotic injection for dogs is the first choice for vets in hospital or clinic settings because the former offers veterinarians complete control over dose volume, frequency, timing, and delivery method.

3.What are the fundamental ingredients for antibiotic injection for dogs?

Antibiotic injection for dogs may seem like a clear liquid but it is full of powerful ingredients. They are mixed in precise portions to prepare a remedy that is perfect to ward off infections. So, let’s read about the principal ingredients present in antibiotic injection for dogs:

Active Component

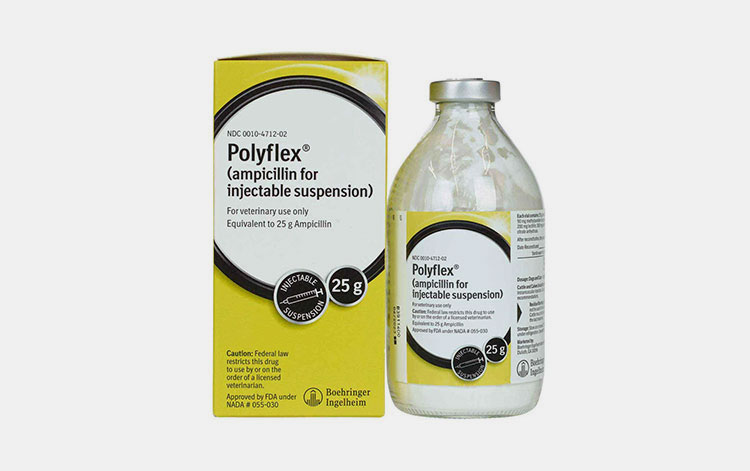

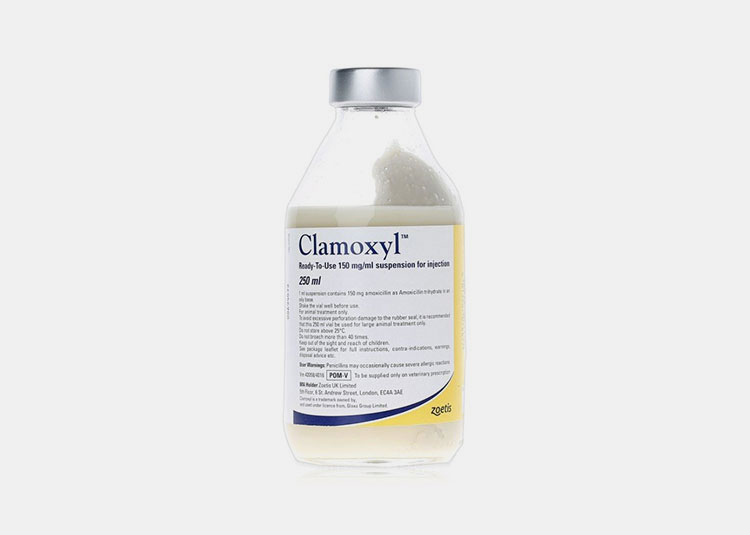

Active compound

It is the main player in the formulation and vital for the efficacy of antibiotic injection for dogs. Yes, you say it is a star of formulation because it is the actual component that combats bacterial diseases by killing bacteria or inhibiting their growth. Some common active components in antibiotic injection for dogs are such as, Ampicillin, Cephalosporin, Gentamicin, etc.

Diluent

Diluent- Picture courtesy: Antibodies Corporation

Its job is to form a liquid formulation by dissolving active ingredients and other excipients. Hence, you can easily inject it. Sterile water for injection and buffered saline solutions are the most frequently utilized for developing antibiotic injection for dogs. On the other hand, you’ll find oily solvents, for instance, propylene glycol or sesame oil in sustained-release formulations.

Stabilizers

Stabilizers- Picture courtesy: EMEDZ.NET

Antibiotic injection for dogs is stable till their expiry period. How is that possible? This is because stabilizers have an integral part in stabilizing formulation. Consequently, it remains potent and efficacious during their storage and distribution.

Usually, manufacturers utilize EDTA to prevent degradation of preparation by metal ions and sodium citrate to maintain pH at the desired range.

Preservatives

Preservatives- Picture courtesy: Healthy starts at home

You’ll only find preservatives in the multi-dose antibiotic injection for dogs. This is because they inhibit microbial contamination after opening of packaging. Benzyl alcohol, phenol, and methylparaben are some common preservatives.

pH Modifiers

pH Modifiers- Aroma Origin

It is essential to maintain the pH of formulation at the preferred and pet-safe range because it minimizes irritation during injection and keeps antibiotic injection for dogs stabilized. So, you have a pH modifier or buffers for this purpose. Sodium bicarbonate and phosphate buffers are a few of the most preferred buffers in this preparation.

4.What are the operational stages in the production of antibiotic injection for dogs?

Most people assume that manufacturing an antibiotic injection for dogs is simply mixing ingredients and loading an antibiotic container. But you should know that it is a series of highly regulated steps that are developed to optimize the sterility and safety of medications.

Here is a complete list of steps in the production of antibiotic injection for dogs for your knowledge:

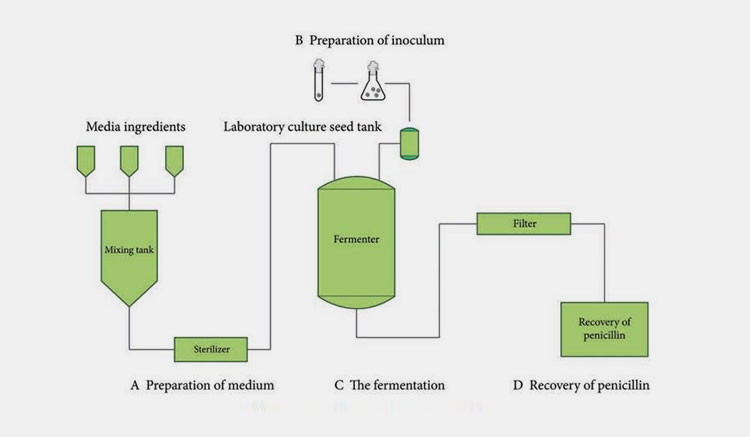

Raw Ingredients Preparation

Production of Antibiotic Injection For Dogs- Picture Courtesy: Brainkart

Just you you’re aware before beginning the actual process of formulating antibiotic injection for dogs, your first step should be the collection and quality checking of raw materials. Here are some steps that occur during the preparation step.

| Cultivation of Culture and Fermentation | If you desire an antibiotic that is naturally derived, then you will cultivate and grow your preferred organism in culture. This organism will make your required antibiotic compound. However, you must carefully examine pH, temperature, aeration, and nutrients during the cultivation period to maximize yield. |

| Harvesting | In simpler words, this step is carried out to collect the antibiotic-containing medium by draining out the complete contents produced during cultivation. Once, you notice that the antibiotic has been created as per the required amount, you withdraw contents from the fermenter machine, where culture is growing. The liquid produced at this step is called fermentation broth. |

| Extraction | Once harvesting is done, now you’ve to isolate the antibiotic from the fermentation broth. At this step, various techniques, for instance, filtration and solvent extraction are used to separate out antibiotics from fermentation liquid. In solvent extraction, the antibiotic is dissolved in the solvent by elevating its temperature and pressure or using ultrasonic waves. |

| Ingredient Concentration | Sometimes, the extracted liquid has little quantity of antibiotic, so, you’ve to concentrate it by evaporating extra solvent. Vacuum evaporation and reverse osmosis are the main approaches that maximize the potency of active ingredients. |

| Purification | After concentrating on the solution, it is passed through various types of filtration systems, such as membrane filters or 0.22-micron filters to achieve the highest purity level of ingredients. This is performed by clearing out impurities or other debris from the solution. |

Solvent Preparation

Solvents- Picture courtesy: Corda Pharma

Alongside the preparation of the antibiotic compound, you must also prepare the sterile solvent. Usually, the solvent is sterile water for injection that is formulated by various water treatment systems, such as multi-effect distillers or reverse osmosis systems.

Other methods like autoclaving or membrane filtrations are also employed to remove smaller particles, microbes, and, other contaminants from dissolution liquid. By this step, you’re ensuring sterility of formulation.

Dissolution and Mixing

Dissolution and Mixing- Picture courtesy: Haltermann Carless

Now, comes the step that is the heart of the production of antibiotic injection for dogs. At this stage, you’ll use large mixers or homogenizers with stirring or agitating systems to thoroughly mix and blend antibiotic contrate in sterile solvents. They are carried out to formulate a stable blend of ingredients.

This blend has every formulation element- from active ingredients to stabilizers, buffers, etc. This results in even dispersion of particles in preparation, ensuring consistent dosing.

Aseptic Filling

Aseptic Filling- Picture courtesy: SHIBUYA CORPORATION

Now, it's time to pack the liquid antibiotic injection for dogs into containers. However, you must take care to do it safely. For this reason, it is vital to utilize automated aseptic filling machines with integrated volumetric filling devices. This allows you the complete control over the filling volume.

In addition to filling, some systems also include volume checking to ensure absolute accuracy in dosing volume. Moreover, the stoppering devices add partial rubber stoppers on the vials. Also, nitrogen flushing is performed post-filling to remove oxygen from the headspace of vials. Failure to do so might cause oxidation of antibiotic injection for dogs.

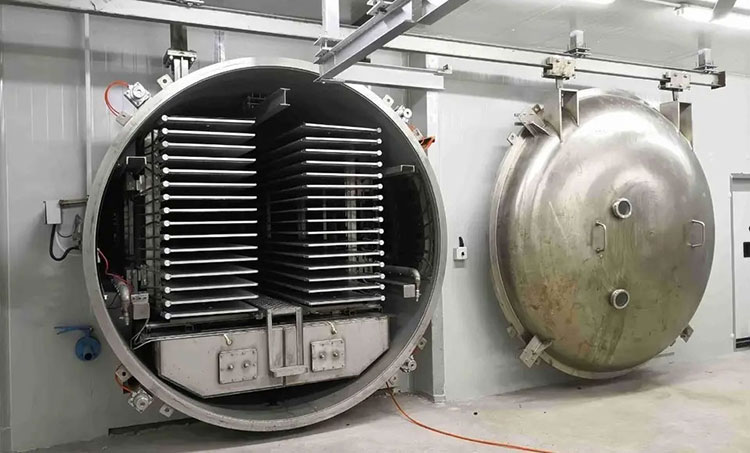

Dry Powder Preparation

Dry Powder Preparation- Picture courtesy: Hardy Paw

In some cases, solvents are evaporated from the antibiotic preparation to create a dry powder antibiotic injection for dogs. In this stage, freeze-drying occurs to evaporate solvents from preparation. This powder is reconstituted before administration with diluent.

Liquid solvent is heated at high temperatures with hot air, resulting in its vaporization. Afterward, on a slight increase in temperature, the remaining solvent is removed, bringing the end moisture content to below 1%. Thus, a fine antibiotic powder is left behind.

Packaging Sealing

Packaging Sealing- picture courtesy: Farmacy

After filling and stoppering, the crimped aluminum caps are placed on the vials to seal vials. The crimping process forms a secure closure on the vial neck by attaching a metal cap. With this step, you can prevent contamination and leakage of antibiotic injection for dogs.

Labeling

Labeling

After that, the labeling step is carried out in the production of antibiotic injection for dogs, where every container gets its own label detailing the information, such as batch number, manufacturing, and expiry date, storage guidelines, and use indication for dog breeds.

Cartoning

Lastly, you’ll see the packing of antibiotic containers into boxes or cartons. The leaflet detailing information about a product is also included in their cartons. At the final stage, these cartons are secured with shrink-wrap to keep cartons and their inner contents safe from damage in transit.

5.What are the key machine systems in the manufacturing of antibiotic injection for dogs?

There are various pieces of equipment integrated in sequential order to manufacture antibiotic injection for dogs. Let’s discuss them one by one:

Fermenter

Fermenter- Picture courtesy: Brau Supply

It is also called a bioreactor. It is a large tank made with stainless steel, where the particular type of microbes is cultured under specific settings of temperature, pH, air, and agitation to manufacture desired quantities of antibiotics. It has automated cleaning and sterilization systems with automated aeration control to boost cell culturing.

Centrifugation Machine

Centrifuge Machine

It is a vital machine in the manufacturing of antibiotic injection for dogs used both before and after the harvesting. Typically, its task is to fractionate the fermentation broth and aid in the separation of microbial cells from liquid material. After starting the separation of solid-liquid components, there might be some particulate materials present in the liquid phase and they are removed with a centrifugation device.

Moreover, after extraction, its function is to recover antibiotic compounds dissolved in organic solvents by removing solid impurities.

Solvent Extraction Machine

AIPAK ENGINEERING Continuous Counter Current Extraction Equipment

Typically, it is utilized to extract antibiotic compounds from microbial cells and medium components. It is vital because, without it, you can’t have purified antibiotics for formulation. It involves solvents that dissolve antibiotic materials by heating and using high pressure.

Column Chromatography Device

AIPAK Engineering Continuous Column Separation Device

You might also know continuous column separation device by the name of resin column. It is composed of several pillars and tanks to separate out antibiotic components from the fermentation broth. It is utilized to obtain purified antibiotics. Its column has an ion exchange resin that absorbs antibiotics from the fermentation broth.

Filtration Machine

Vacuum Filtration Equipment

This is composed of a conical cup, screw pusher, and a vacuum pump which is important in the ultra-filtration of antibiotic injection for dogs. With the help of its vacuum pump, a suction force is generated that improve the flow of mix from one phase to other and leaving unwanted suspended particles behind ensuring a cleared solution.

Water Treatment System

AIPAK ENGINEERING Water Treatment Plant

Water treatment plant is very integral that you use water for injection in preparation for antibiotic injection for dogs. Different approaches, for example, reverse osmosis, deionization, and distillation are utilized to purify water. This unit is vital in the sterile manufacturing of antibiotics, as it clears out various endotoxins, microbial colonies, particulates, debris, metal ions, salts, and organic substances from water.

Vial Filling Production Line

AIPAK ENGINEERING Vial Filling Production Line

Vial filling production line is an integration of several machines, for instance, an unscrambling unit, ultrasonic washing system, sterilization unit, filling and stoppering machine, and capping machine. These units operate together to deliver high-quality results.

The unscrambling unit is the first system that receives a large load of vials and orients them in the proper order. This aids in the alignment of vials and prevents their damage down the line. After that, washing systems use high-frequency ultrasonic rays or water jets to fully clean vials from both inside and outside.

Next in line is the depyrogenation or sterilization tunnel that carries out the sterilization of vials with the use of dry heat or hot air. It makes the vial devoid of microorganisms. Afterward, you’ve got a vial filling and stoppering machine that is the heart of the vial production line.

With the utility of an advanced piston or pump system, it accurately dispenses antibiotic injection for dogs in the vials. Later, the vials are partially stoppered to perform freeze-drying.

Freeze-Dryer

AIPAK Vacuum Freeze-Dryer

Yes, it is also named a lyophilizer. This machine is ideal for evaporating solvents and altering antibiotic injections for dogs into dry powder without using heat. First, the product solution is frozen at an extremely cold temperature of around -40°C in this equipment. This changes water into ice. Subsequently, under a deep vacuum environment, ice is directly transformed into vapor, producing a dry powder of antibiotics.

CIP /SIP system

AIPAK ENGINEERING Clean Steam Generator

For the CIP/SIP process, the clean steam generator is used in the final stages of the production of antibiotic injection for dogs. The unit mainly works by using steam heat and deionized water for cleaning units used in the production process and is popular in health-related sectors as a first choice of disinfectants and sterilizing equipment. The machine has major units based on evaporating units, pre-heating units, and entire automatic digital components.

Labeling System

AIPAK Labeling machine

After complete stoppering and sealing, now lyophilized vials of antibiotic injection for dogs are moved to labeling machines, whose job is to stick pre-printed labels detailing batch numbers, expiry dates, and product facts on vials. Sometimes, QR codes or barcode labels are printed by this machine and are applied to vials for better tracking of the batch.

Cartoning Machine

AIPAK Cartoning Machine

Finally, your vials are ready for the cartoning machine. The cartoning machine pack labeled antibiotic injection for dogs vials in cardboard or paperboard boxes. It takes blank sheets and converts them into boxes by orientation, folding, tucking, loading, and sealing them.

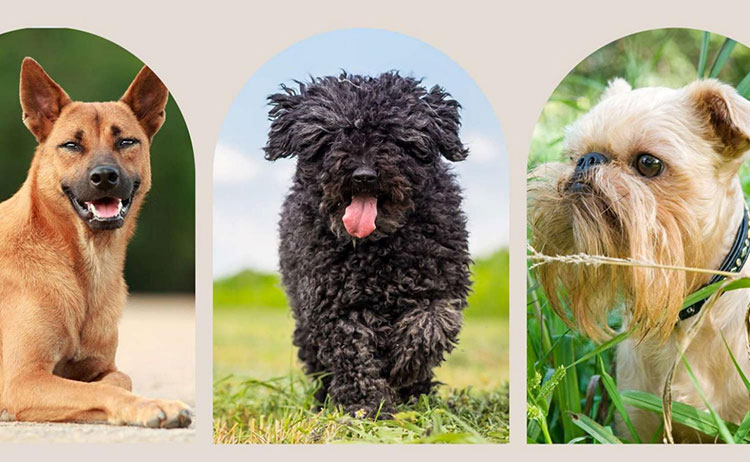

6.Is antibiotic injection for dogs safe for every dog breed?

Different dogs breeds- Picture courtesy: Martha stewards

In general, yes! Antibiotic injection for dogs is completely safe for most dog breeds when your vet properly prescribes and administers it. However, here is a catch, not every breed responds to antibiotic injection for dogs in the same manner. That’s why you need the expertise of a pet doctor.

Also, there are many dog breeds that have sensitivity to certain medications, which impact how their bodies react to certain antibiotics. On the other hand, some dogs have minimal boy fat, which affects the absorption of antibiotics.

As breed size influences drug metabolism, therefore, vets have to perform weight-based dosing (mg/kg) and in some cases, might have to make breed-specific dose alterations.

7.What are various packaging styles for antibiotic injection for dogs?

There are two primary packaging styles for antibiotic injection for dogs, including:

Glass Vials

Glass Vials- Picture courtesy: PETCO

Yes, your guess is on the spot. Glass vials are the most frequently seen packaging for antibiotic injection for dogs. Indeed, pharmaceutical manufacturers favor them because of their extreme protection, water resistance, airtight hermetic sealing, lightweight, and convenience.

Both single and multi-dose vials are available for antibiotic injection for dogs. Single-dose ones are utilized once and then discarded, whereas, multi-dose vials are excellent for the treatment of many dogs.

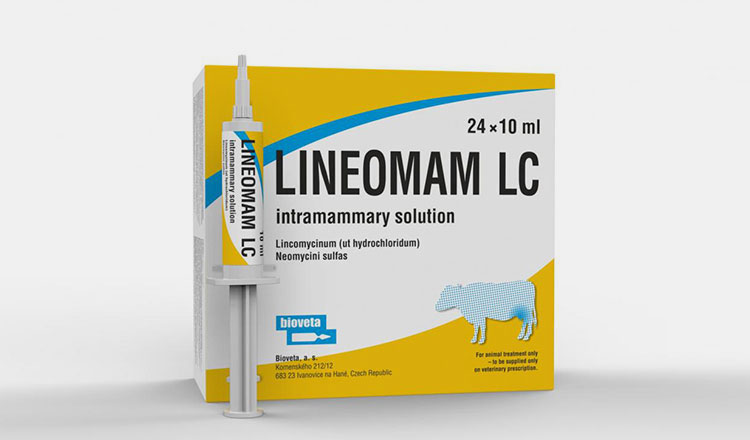

Prefilled Syringes

Prefilled Antibiotic Syringe- Picture Courtesy: Bioveta

These are becoming more widespread today in dog care because of their ease of usage. They have accurate pre-measured doses, which saves vets from measuring the right dose and then injecting it. It also lowers preparation time and is easy to carry on field trips.

8.Can you list some common sealing closures of antibiotic injection for dogs?

Sealing closures are vital in keeping your precious medications safe, pure, and secure. Without them, you might have product contamination and leakage on your hands. So, let’s explore some handy sealing closures of antibiotic injection for dogs:

Rubber Stoppers

Rubber Stoppers

They are also named elastomeric closures because of their structural composition. They are composed of hardened rubber (butyl or silicon rubber)- known for its enhanced strength and durability. They are favored due to their sterile airlock barrier. They allow you ease in accessing med with a needle and resealing, thereby, letting you multiple withdrawals while maintaining sterility.

Aluminum Seals

Flip-Off Aluminum Seals

They are comprised of two parts- metal casing and plastic button. You have to flip or lift the plastic part to puncture the rubber stopper present underneath the flip-off aluminum ring. Typically, they act as the first line of defense for vial protection.

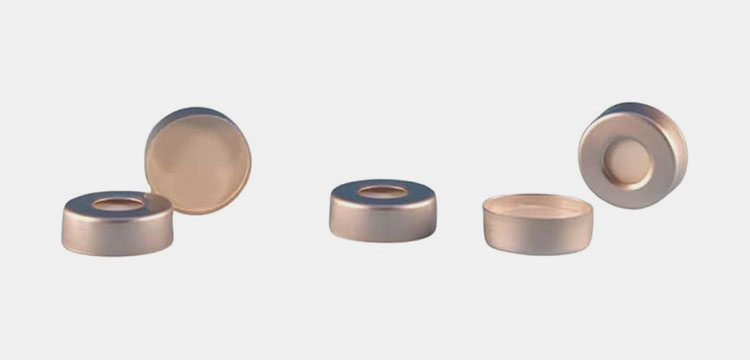

Crimp Seal Caps

Crimp Seals- Picture Courtesy: Sigma-Aldrich

A specialized tool called a crimping tool is utilized for sealing these aluminum caps on vials. This sealing closure is created by tightly squeezing the aluminum cap around the neck of vials, yielding a strong mechanical seal.

Lyophilization Stoppers

Lyophilization Stoppers

They are customized stoppers specifically developed for powdered antibiotics obtained from lyophilization. They are made from butyl rubber, bromobutyl rubber, or chlorobutyl rubber. Their multiple channels and typical shape aid in the ejection of moisture vapors from vials during the freeze-drying process.

9.What are the different doses of antibiotic injection for dogs?

Different Doses Of Antibiotic Injection- Picture courtesy: SingleCare

Before reading the answer, you must understand that there is no one-size-fits-all antibiotic dose for every dog. It stems from the fact that the dose of antibiotic injection for dogs is usually calculated by considering the type of antibiotic, your dog's weight, the severity of infection, and the choice of veterinarian. However, here are some common doses for your review.

| Antibiotic | Frequent Dose Range (per kg body weight) | Administration Timings |

| Ceftriaxone | 20–30 mg/kg | Once daily |

| Cefazolin | 20–25 mg/kg | Every 8–12 hours |

| Enrofloxacin | 5–10 mg/kg | Once daily |

| Gentamicin | 4–6 mg/kg | Once daily |

| Penicillin G | 20,000–40,000 IU/kg | Every 6–12 hours |

| Oxytetracycline | 10–20 mg/kg | Every 24–48 hours |

10.What are some potential adverse reactions of antibiotic injection for dogs?

Although antibiotic injection for dogs is considered life-saving drugs, they aren’t completely risk-free. So, let’s have an insight into some potential adverse reactions of this formulation.

Potential Adverse Reactions- Picture courtesy: Dr. Marty

Allergic Reaction

They are quite rare but antibiotics, for instance, penicillin and cephalosporin classes are more frequently linked with allergic reactions in dogs. These hypersensitivity reactions have some evident signs, such as swelling on the face and lips, trouble in taking breath, wheezing, rashes, itching, or losing consciousness.

Gastrointestinal Distress

These reactions occur less frequently when antibiotic injection for dogs when compared with oral antibiotics. However, still some dogs experience vomiting, diarrhea, stomach cramps, and reduced appetite.

Injection-Related Reactions

Due to irritating chemicals or contaminants in antibiotic injection for dogs, your dogs might acquire these adverse reactions. Sometimes, they can also happen due to bad administration techniques. They include pain, redness, inflammation, or blistering at the injection site.

Serious or Fatal Side Effects

Although they are quite rare in dogs, on the administration of certain antibiotic injection for dogs, your furry companion may get neurological reactions, like involuntary shaking, confusion, or fits. They may also experience renal failure with gentamicin treatment.

11.How long is the expiry period for antibiotic injection for dogs?

Expiry Time Of Antibiotic Injection For Dogs- Picture courtesy: Dogster

If you want to give safe and potent antibiotic injection to dogs, then you must learn about its shelf-life and expiry period. Generally, many commercially available antibiotic injection for dogs have an expiry period of 1 to 2 years from their manufacturing date.

These liquid formulations often decompose quickly because they have water in them and are fairly intolerant to changes in light, temperature, and impurities. On the other hand, lyophilized antibiotic injection for dogs are good for 2 to 3 years. Their longer usage period is due to their minimal moisture content.

However, once you’ve reconstituted this injection, you’ve to use it within 24 hours.

12.What are frequent problems and their remedies in the manufacturing of antibiotic injection for dogs?

Despite your utmost efforts, you still face tricky challenges in the manufacturing of antibiotic injection for dogs. But here is good news for you, you can easily resolve them with the right know-how and training. To increase your understanding of problems, we’re penning issues in the manufacturing of antibiotic injection for dogs and their solutions:

Growth of Microbes

Growth of Microbes- Picture courtesy: Head up for Tails

One of the biggest challenges during the manufacturing of antibiotic injection for dogs is bacteria and fungal propagation in products. It can occur at any step, like mixing, filling, or sealing.

Remedy

To solve this issue, you must carry out manufacturing in a proper cleanroom environment with ISO 8 certification. Moreover, these rooms must have HEPA filtration integration. Also, you must use aseptic filling lines that have lower human involvement. Similarly, make sure to test your formulation after each step to monitor biomass growth in it.

Wrong Fill Quantity

Wrong Fill Quantity- Picture courtesy: SuperTail

It can have some serious consequences, such as the underfilling of containers translating into underdosing, whereas, overfilling them surely increases cost and impacts antibiotic potency.

Remedy

You can remedy these problems by using accurate volumetric loading devices, for instance, peristaltic or pump systems. Secondly, make it a routine to calibrate machines daily. In addition, integrate auto-rejection equipment to ensure no container having wrong fill volume proceeds down the line.

Instability of Active Ingredients

Instability of Active Ingredients- Picture courtesy: Dogs Naturally

Certain antibiotics, for example, cephalosporins or penicillins have poor dissolution in solvents or might quickly fall apart upon a slight change in environment.

Remedy

Some suggestions to rectify this problem are as follows: incorporate suitable buffers and pH stabilizers to boost the stability of active ingredients. Moreover, the addition of chelating agents and stabilizing elements helps in maintaining a stable formulation. Also, it is recommended to use closed mixing tanks with temperature control systems to keep the temperature at the desired range.

Heat Intolerance Upon Sterilization

Heat Intolerance Upon Sterilization- Picture courtesy: Dogs Naturally

You’ll notice that some antibiotics have heat intolerance so they react poorly to temperature in autoclaves and degrade.

Remedy

You can skip end sterilization of antibiotic injection for dogs by filling and sealing it under an aseptic environment. You can use sterile filtration instead of heat sterilization for these antibiotics. Lastly, always remember to use pre-sterile components, such as vials and stoppers.

Conclusion

Antibiotic injection for dogs is an effective line of defense and immunity helper when your furry friends get bacterial infections. Understanding the science behind its manufacturing, its safety profile, and potential side effects goes a long way in paving the way for better dog care. This guide aims to answer your key questions about antibiotic injection for dogs: benefits, shelf life, production, equipment, and problems. For those in the vet pharma industry exploring investment in the production line for antibiotic injection for dogs, you should consult the machine catalog of AIPAK ENGINEERING. We aim to satisfy each and every one of your operational needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours