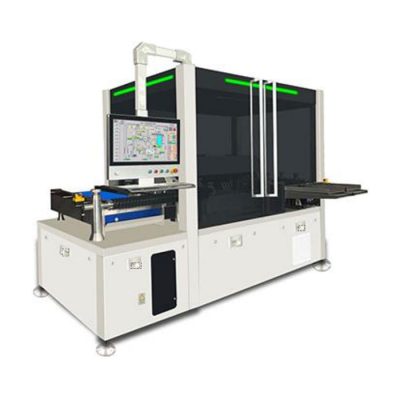

Automatic Bottle Outside Cleaning and Drying Machine

AIPAK ENGINEERING automatic bottle outside cleaning and drying machine is widely used for ampoules, vials, oral liquid bottles, capsule bottles, etc. outside cleaning and drying, as after these preparation bottles are filled with drugs (including highly allergic antibiotic drugs such as penicillin, antibacterial drugs such as cefepime, antineoplastic drugs such as paclitaxel, fructose diphosphate and oil drugs, etc.) and plugged and capped, the outer surface of the preparation bottles will be contaminated by drug dust or liquid adhesion to a certain extent, so it is important to clean the outer surface of the preparation bottles, in this way, it can be ensured that the preparation bottle can be closely labeled in the early stage of the packaging process, and the personal and working environment protection of the late packaging staff who come into contact with the drug and the medical staff who come into contact with the drug in the hospital or pharmacy are not subject to adhesive dyeing, and it can also be ensured that the surrounding environment will not be polluted during the storage and transportation of the drug.

Automatic Bottle Outside Cleaning and Drying Machine Features:

1.The formulation bottles can be continuously or intermittently conveyed for fully automatic external surface washing and drying operations.

2.The cleaning medium can be selected among injection water, purified water, and drinking water. Detergents and surfactants can also be added to enhance the cleaning effect, ensuring that any adhered drug residues on the bottle surface are completely removed.

3.The cleaning process includes rough washing and fine washing. The fine washing water can be recycled for rough washing, which reduces the consumption of cleaning media and meets energy-saving and emission-reduction requirements.

4.The drying process does not require heating of the drying medium. Instead, it uses normal-temperature high-pressure air, assisted compressed air, and vacuum air to dry the outer surface of the formulation bottles at room temperature, achieving energy-saving and consumption-reducing effects.

5.It is suitable for cleaning and drying formulation bottles ranging from 1 ml to 250 ml. Using 10 ml vials as a standard, the cleaning speed can reach up to 1,000 bottles per minute. Specification changeover is quick and convenient, taking about 10–15 minutes, and recipe programs are available for different bottle sizes.

6.The temperature, flow rate, and pressure of all working media can be automatically adjusted to ensure that each formulation bottle is properly cleaned before entering the next process.

7.After cleaning and drying, the inspection pass rate of the bottles is high. The labels adhere firmly without peeling or fading, and they remain intact and unstained throughout the product’s shelf life.

Automatic Bottle Outside Cleaning and Drying Machine Technical Specification:

| Item Name | Technical Parameters | |||

| Application Range | Itcancleaningand dryingoutside of1-250mlcontainer (shaped bottlescan becustomized) | |||

| Model | APKWX-300 | APKWX-400 | APKWX-500 | APKWX-600 |

| Cleaningand Drying Speed | 300 bpm | 400bpm | 500bpm | 600bpm |

| Working Height | 900±50mm | 900±50mm | 900±50mm | 900±50mm |

| CleaningWaterConsumption | 300/h | 400/h | 5001/h | 500L/h |

| Compressed AirConsumption | 0.6MPa-20m³/h | 0.6MPa-25m³/h | 0.6MPa-30m³/h | 0.6MPa-40m³/h |

| Voltageand Power | AC380V/50HZ/8KW | AC380V/50HZ/10KW | AC380V/S0HZ/10KW | AC380V/50HZ/12KW |

| Dimensions(mm) | 2360×1200×2400 | 2050×1200×2400 | 2500×1200×2400 | 2700×1900×2400 |

| Weight | 1000Kg | 1200Kg | 1500Kg | 1800Kg |

Vial Filling Line Related Products