Baby Cough Syrup Filling Machine: The Complete FAQ Guide In 2025

Have you ever paused to think about how each bottle of baby cough syrup is filled so precisely without wastage of a single drop? This is all possible because of the remarkable pharmaceutical technology and that is cough syrup filling machine.

The baby cough syrup filling machine is working silently to make a high sterile and hygienic syrup that can cure the baby cough. In this complete FAQ guide of AIPAK ENGINEERING, you will be able to explore everything about this machine. In the end, you will have a complete information related to this machine like what are the components, working principle, its maintenance and why is it essential? So, let’s start!

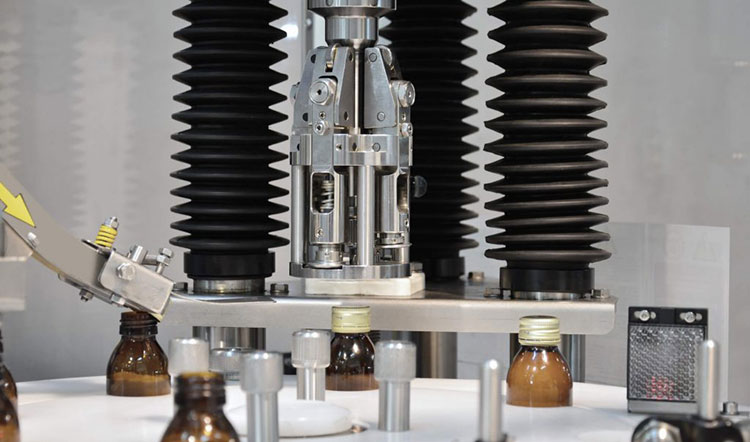

1.What is baby cough syrup filling machine?

AIPAK engineering syrup filling production line

Baby cough syrup filling machine is a type of pharmaceutical filling equipment which is used to fill the liquid formulations like baby cough syrup through the filling nozzles into the bottles. It operates in clean and hygienic environment which ensures the sterility of the cough syrup. It can handle variety of sizes and materials of bottle and filled them with sterile cough solution.

2.How can you get advantages by using baby cough syrup filling machine?

Have you ever paused while using baby cough syrup filling machine and thought what kind of advantages you will get by using this machine? The following are the benefits you can get by using this machine are as follows:

Accurate and safe filling:

Accurate and safe filling by the baby cough syrup filling machine

When you are dealing with baby cough syrup, every drop of syrup accuracy matters a lot. The bottles should be filled with accurate dose. The machine ensures you the bottles are not over-filled or under-filled with baby syrup. The filling occurs in sterile and clean environment so, it protect the baby’s health.

Faster production:

Faster production of the syrup bottles by the syrup filling machine

The baby cough syrup filling machine is automatic and can fill thousands of bottles per minute without compromising the safety of the product. In contrast, if you wants to fill the bottles with baby cough syrup, it takes a lot of time and cross contamination chances are also high.

Same quality every time:

If the pouring of syrup in bottles are done manually, then chances of bottles to fill unevenly and hence, looks different but by using baby cough syrup filling machine, each bottle is filled and sealed in exactly the same way. This ensures that your products look professional and parents will also be satisfied with the cough syrup.

Lowers labor cost:

Lowers labor costs

This filling machine can do all the tasks from filling of bottles with baby cough syrup to the sealing of the bottles. It can also connect with other machines like labeling machine, as well. So, you can get all the tasks in one machine and don’t you need labors for these tasks. This can lower the labor costs.

Less product wastage:

If you do the filling manually, then it leads to spills and syrup sticking to containers. But the baby cough syrup filling machine has special type of nozzles that adjust to the neck of the bottle and fills the bottles accurately without spilling or wastage of the product. In this way, you can save the valuable baby syrup and money.

3.Enlist the industries that can get benefits by using baby cough syrup filling machine?

There are various industries that can be benefited by using baby cough syrup filling machine. The industries or companies where this machine can be used are listed below:

Pharmaceutical industry:

Pharmaceutical industry-Picture courtesy: tixylix.co.uk

This is the top industry which can get benefits by using baby cough syrup filling machine. Industries can make syrups, medications and liquid formulations and fill them with various sized bottles with precise and accurate dosage. The filled baby cough syrup ensures the safety and quickly fills thousands of bottles.

Nutraceutical and herbal industry:

Nutraceutical and herbal industry

Many herbal industries manufacture herbal cough syrups for babies. For the filling of these syrups into the bottles, you can step towards the baby cough syrup filling machine. This machine accurately and precisely fill the syrup in to the different sized containers.

Pediatric Medicine Manufacturing industry:

Pediatric Medicine Manufacturing industry

Many companies and industries just focus on the infants and toddlers medication preparation. Their solely aim is to make the baby cough syrups with high precision and safety. So, cross contamination must be avoided which can be possible if manual filling occur. For the filling purpose, you can use baby cough syrup filling machine. This machine guarantee you the safety of each drop of baby cough syrup.

Cosmetic and Baby Care Liquid Products making industry:

Cosmetic and Baby Care Liquid Products making industry

Some industries make baby care products that targets the well-being of the infants and toddlers. For example, vitamin syrups, and wellness drops etc. these are not pharmaceutical but their dose and precise filling is necessary. Similarly, cosmetic industry can make various skincare liquid products for babies and for filling these products, you can use baby cough syrup filling machine.

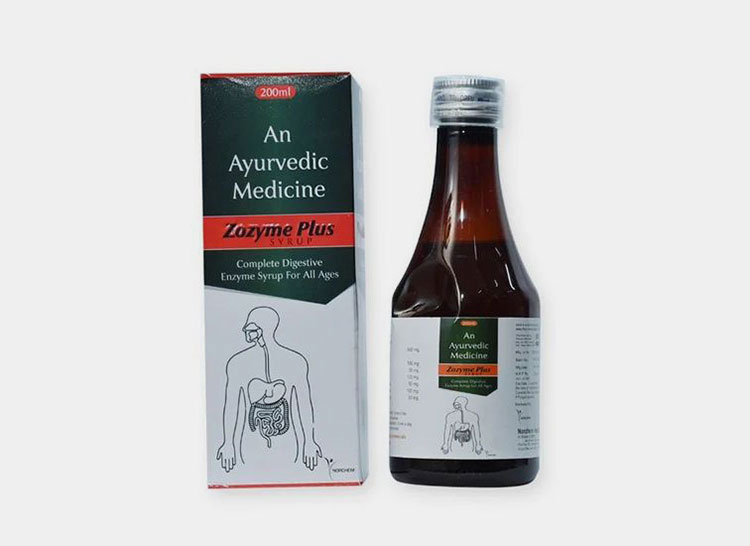

Ayurvedic and Homeopathic Industries:

Ayurvedic and Homeopathic Industries

Ayurvedic and homeopathic industry targets to make a safe and natural syrups for the babies. For filling of these liquid formulation into the bottles, you can use baby cough syrup filling machine. By using this machine, the natural ingredient based syrups are filled in the required containers without the wastage of single drop of syrup. You should remember, this machine guarantee you the sterility of the products.

4.Are there types of baby cough syrup filling machine?

There are various types of baby cough syrup filling machines. They are divided based on automation level and filling mechanism.

Based on automation level:

Based on automation level, they are divided into three types:

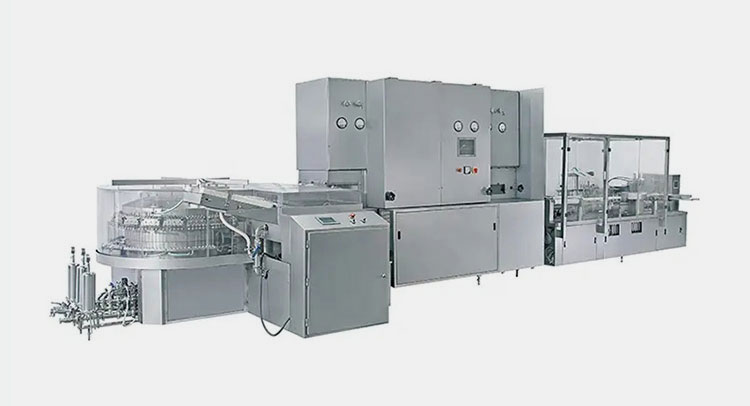

Fully-automatic baby cough syrup filling machine:

AIPAK ENGINEERING fully-automatic baby cough syrup filling machine

The fully automatic baby cough syrup filling machine is advanced machine which is used in industries where thousands of bottles are filled in a day. This machine can fill the bottles with high precision and accuracy, cap and seal the bottles. The bottles move along the conveyor belt and with the help of nozzles, each bottle is filled with baby cough syrup without the wastage of a single drop.

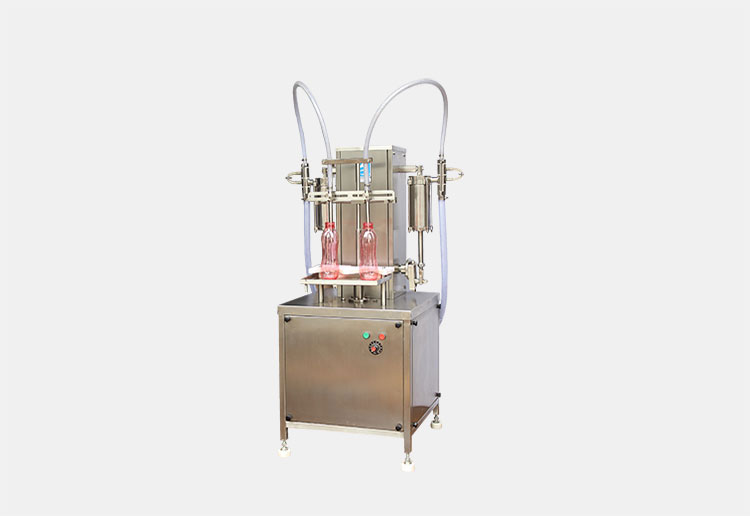

Semi-automatic baby cough syrup filling machine:

Semi-automatic baby cough syrup filling machine- picture courtesy: bhalani group

As the name indicates, this machine needs the assistance of an operator. The operator placed bottles in the machine but the filling takes place within the machine. This ensures the filling is done in a highly sterile environment. It is suitable for those companies or industries that are still growing and wants to produce medium batch of the products.

Manual baby cough syrup filling machine:

Manual baby cough syrup filling machine

In manual baby cough syrup filling machine, the operator move the paddles or operating lever and hence, filling of baby cough syrup into the bottles occur. As it is low cost machine so, you can use it for the startup businesses. Because this machine is time consuming and produce less products. This machine is easy to clean and maintain.

Based on filling mechanism:

On the basis of filling of cough syrup into the bottles, there are two types and that is:

- Piston type cough syrup filling machine

- Peristaltic pump cough syrup filling machine

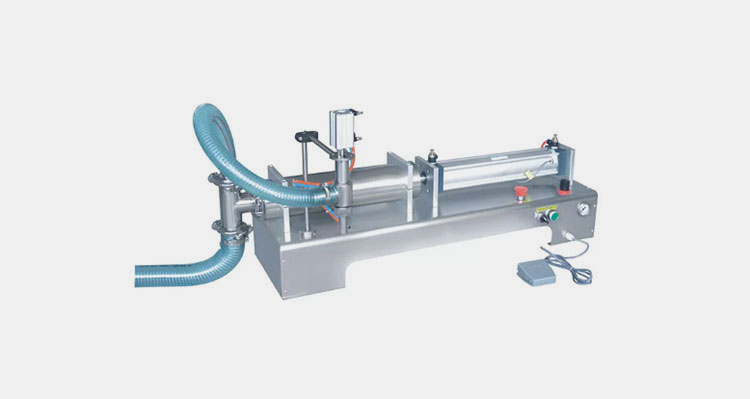

Piston type cough syrup filling machine:

Semi automatic liquid piston filling machine-Picture courtesy: vkpak.com

This machine use piston mechanism to push and fill the baby cough syrup into the bottles. This can control the volume of syrup and make sure each container equally receive the syrup. It can handle various viscosities liquid so, best for thick liquids syrups or herbal formulation.

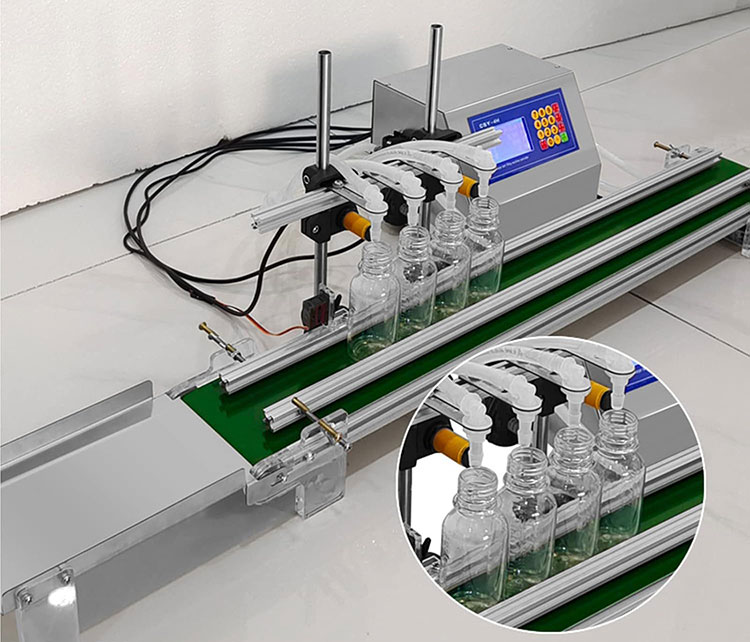

Peristaltic pump cough syrup filling machine:

Automatic Peristaltic Pump Based Liquid Filling Machine-Picture courtesy: nkpharmamachinery.com

Peristaltic pump, also known as roller pump, works by squeezing a flexible tube with a roller. As the roller moves, they trap the liquid in a small sections of the tube and push the liquid from the inlet side to the outlet side. Because the liquid syrup only touches the inlet side so, the contact with other machine parts is avoided. In this way, liquid syrup remains safe and free from contamination. This pump is suitable for sensitive liquids like blood in dialysis machine and baby cough syrup.

5.What are the components of baby cough syrup filling machine?

You see the baby cough syrup filling machine in your industry but have you ever wondered what’s cooking inside the machine. There are various components of the baby cough syrup filling machine. These are as follows:

Filling nozzles:

Filling nozzles

The nozzles are the small outlets through which liquid syrup is poured into the bottles. The filling machine has a several nozzles which fills several bottles at the same time. This machine can handle various sized and width bottles because these nozzles are adjustable and can be adjusted accordingly.

Dosing system( piston or pump):

Dosing system ( piston or pump)

This system is like a heart in the filling machine which can measure the syrups before sending it to the nozzles. The piston dosing is ideal for the thick liquid formulation while the peristaltic pump is ideal for sensitive baby liquid products. This system ensures every bottle has the exact same amount of syrup and consistency is achieved.

Conveyor belt:

Conveyor belt

It is the station which is movable and can helps in the transportation of bottles from one station to another. At the one end of the station, you will find the empty bottles which are then travelled to the next station for filling and then capping and sealing. This component is very important in this machine because it keeps the work in continuous way.

Bottle feeding system:

In some machines you will find the bottle feeder. It takes a bulk bottles which are then upright in direction and then placed onto the conveyor. This upright of bottles and then placing them onto the conveyor, ensures you the precisely and without any interrupting the process, bottles are filled with cough syrup. This reduces the cost of labors.

Capping unit:

Capping unit

The caps of the bottles are placed in a hopper. From the hopper, caps are picked up and placed on each bottle. The caps are then needed to tighten up. For the sealing of caps, torque is applied. After this force, you will get a sealed bottle which preserve the cough syrup inside it.

Frame and housing:

All the components of the filling machine is enclosed in stainless steel body. This body protects all the components and ensures the safety, sterility of the product. The pharmaceutical grade stainless steel body ensures the sterility and safety of the baby medicines.

Control panel:

Control panel

The control panel is like a brain in the machine. In this machine, you will find the buttons and touch screen through which you can adjust the volume of the liquid syrup, speeds and examine the performance of machine system. The operator can easily adjust the troubleshoots easily.

6.Elaborate the working steps of baby cough syrup filling machine?

Have you ever go to the pharmacy and put a glance at the shelves and wondered how the syrup bottles are beautifully and precisely filled? This is due to the hardworking of the sleek machine and that is baby cough syrup filling machine. Let’s explore the step by step procedure that takes place within this machine.

| Steps | Explanation |

| Bottle feeding

Bottle feeding |

In the first step, empty bottles are fed into the conveyor belt by the operator or placed automatically by the machine. The bulk bottles are then arrange by the feeder in the upright direction in order to avoid misalignment. A smooth and steady feeding process avoids jamming in the machine. |

| Bottle conveying

Bottle conveying |

The conveyor has an adjustable guides that can adjust different bottle sizes and shapes. The bottles move along the conveyor belt to the filling station. It has a controlled speed that can carry the bottles to the filling station at the right time. |

| Dosing | Before filling the syrup into each bottle, the precise volume of the cough syrup should be adjusted that goes into each bottle. It may be through piston pump or through peristaltic pump. On the control panel, you should adjust the filling volume and machine will repeat it consistently for every bottle. |

| Syrup filling

Syrup filling |

Now, the tremendous twist and magic will occur. Each nozzles will adjust over the bottles and at the right time, these sophisticated bottles are filled with a measured volume of magical syrup liquid. It prevent the mess and wastage of the product. You can get thousands of filled bottles in a day, so this machine also saves time. |

| Bottle indexing | If rushing and moving of filled liquid bottles immediately after filling then you do you expect? Off course spills occur. To avoid spilling, indexing system stops and spaced bottles and prevent them from rushing off. In this time period, the syrup is settle down. It helps in maintaining the neat and clean production line. |

| Capping

Capping of the bottles |

After that, the cap feeder takes the cap from the hopper where caps are stored. Each bottle is placed with a cap for the sealing purpose. The torque is applied which is the force that keeps the cap tight. The tight sealing ensures the cough syrup inside the bottle free from contamination, dust and germs. As the baby immune system is in developing stage, so the safety of the product is very essential. |

| Labeling of the cough syrup bottles | In this production line, the filled and sealed syrup bottles are then processed in to the labeling machine. The pre-print labels are already place in the machine and with the help of roller, the prints are labeled each syrup bottle. The labels include the ingredients, dose, instruction of use, batch number etc. this ensures the satisfaction of parents for using the cough syrup for their children. |

| Collecting and packing

Collecting and packing of the bottles |

The labeled baby cough syrup bottles are now ready to leave the production line. Bottles should be collect in trays. These bottles are ready for the packaging. in the cartoning machine, boxes are made and fed the syrup bottles in to each carton. These cartons should be sealed and now, ready for storage and shipping. |

7.Can a baby cough syrup filling machine handle different sized bottles?

Different sized bottles-Picture courtesy: antpackaging.com

Yes, a baby cough syrup filling machine can handle different sized bottles because of the following reasons:

The advanced filling machines has adjustable guides and holders that can be adjusted according to the height and size of the bottles.

The filling nozzles in the machine can be lowered or raised to match the height of the bottles.

You can adjust nozzle height and spacing to match the new sized bottles.

You can switch the bottle caps heads according to the bottle size.

You can also adjust the filling volume settings on the control panel.

8.Is a baby cough syrup filling machine suitable for both glass and plastic bottles?

Plastic and glass bottles

Do you want to use glass bottles for premium look of the products and plastic bottles due to their light weight? Are you wondering is the baby cough syrup filling machine can handle both glass and plastic bottles? You can definitely filled both plastic and glass bottle with a syrup by using this machine. There are separate machines also available for glass and plastic bottles handling. With the help of these machines, you can fill various types of bottles. The reasons why:

- It has adjustable conveyor and bottle holders that can hold both glass and plastic bottles without slipping.

- The filling nozzles have springs and are adjusted according to the type of bottles used.

- The caps sealing is done by applying the right torque. As the glass bottles are fragile so, less torque is required for the cap sealing and vice versa.

9.How to maintain the baby cough syrup filling machine?

The cough syrup filling machine is working hard to produce a safe, hygienic and effective cough syrup bottles for your infant but in returns, it also expect a care to run smoothly, safely and for many years. Here are some steps that should be followed to maintain the machine. These are as follows:

| Steps to be followed | Why is it important |

| Regular Cleaning After Every Batch | You should clean the filling nozzles and dosing system with clean water and cleaning solution after each batch production. You should clean the parts of the machine that are in contact with the syrup. This will prevent contamination between batches and you will have a sterile syrup for your infants. |

| Lubricate Moving Parts

Lubricate moving parts |

You must be surprised by knowing that the unusual and noise creating sound of the machine is due to friction between machine parts. But you don’t need to be worry because you can apply food grade pharmaceutical lubricants to the machine parts like belts, conveyor and bearings. By doing this, the friction will be prevented and the machine will work quietly and efficiently. |

| Inspect Nozzles and Pumps Regularly

Inspect nozzles |

You might be concern about the filling dosing to prevent the uneven filling. For your satisfaction, always check the nozzles and pumps for leaks and cracks. Because the leaks and cracks will perforate the syrup and the chances of uneven filling is high. |

| Check the Capping and Labeling Units | Inspect for the capping head to apply proper torque. You should also check the labeling unit for proper labels and to prevent the misalignment. This make sure a professional and leak proof bottles. |

| Keep Electrical and Control Panels Dust Free | You should always check for the wiring. Also, make sure to wipe the control panel. You should also ensure to clear the ventilation slots. This will prevent the overheating and damage to the machine. |

| Use Only Recommended Cleaning Agents and Spare Parts | You should always use the manufacturer approved chemicals for the cleaning purpose. You should also replace the recommended spare parts. This will protect machine warranty and ensures safety compliance. |

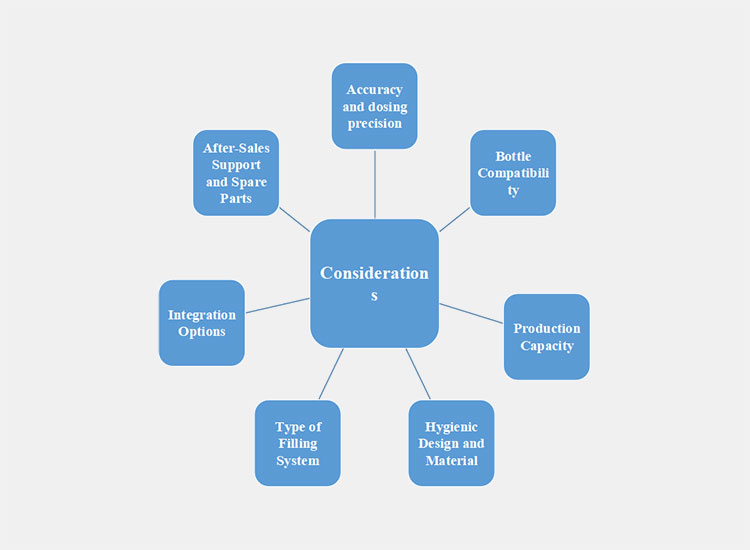

10.What should you consider while buying a baby cough syrup filling machine?

When you go to a market and want to invest on the machine is not an easy as it seems. You must have to choose the right machine for filling the baby cough syrup into the bottles. So, before investing on or buying the machine, you must keep the following points in your mind and should be carefully considered. These are as follows:

Accuracy and dosing precision:

As the baby medicines require strict dosing so, always look for the machine that can consistently fill the bottles. The underfilled and overfilled bottles should be prevented.

Bottle Compatibility:

You should also check for the machine that can handle different sized and shaped bottles. In this way, you will able to produce different variety of syrup bottles in various industries. You can also check for the bottle material compatibility that is, if the machine is flexible enough to handle the glass and plastic bottles or not.

Production Capacity:

Before buying the filling machine ask yourself, how many bottles you want to produce per hour or per day. According to your decision, you can invest on manual, semi-automatic and fully automatic syrup filling machine.

Hygienic Design and Material:

Baby syrup must be free from contamination so, always look for the machine which is made up of stainless steel. Make sure machine is GMP and FDA certified. It should be easy to clean and can easily be sensitized after each batch because baby syrup must be free from dust and contamination.

Type of Filling System:

Before investing on the filling machine, ask yourself, is the syrup you want to fill in bottles are viscous or sensitive syrups? If it is thick syrups, then you should invest on piston type filling machine while for the sensitive products, you should invest on peristaltic pump filling machine.

Integration Options:

If the filling machine is integrated with other machines, then it can save your time and labor cost. So, make sure the syrup filling machine can be integrated with other machines like labeling and cartoning machine etc. and form a complete production line. This will prevent the cross contamination and in one filling line, all the process will be done which reduce the consumption of time and labor costs.

After-Sales Support and Spare Parts:

You must choose a manufacturer or supplier having good reputation in training etc. the supplier must provide a team for training, after sale support and should also provide you the spare parts. This ensures you will not feel downtimes if you needs repairing the machine parts.

Conclusion:

It is concluded that in 2025, baby cough syrup filling machine is not just a piece of machine but it is an important tool in pharmaceutical industry. Other industries can also get benefited by using this machine as it can be used for the filling of various viscosity liquids. It can adjustable filling nozzles so, can be used for various sizes and shapes of bottles. You can choose the baby cough syrup filling machine according to your budget and demand of production of products. You should choose a machine that is made up of stainless steel and meets the international certification. We, AIPAK ENGINEERING, is providing you a baby cough syrup filling machine that is of advanced technology and meets your expectations. For more information, contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours