Allergic Cough Syrup Filling Machine: The Complete FAQ Guide In 2025

Have you ever wondered how the syrup that cure your allergic cough is filled into bottles? Is there a machine responsible for packing these products? Yes- there is allergic cough syrup filling machine, and it carries out this task perfectly. Allergic cough syrup requires an accurate filling, precise dosing with no germ’s entry, like other syrups.

You may have noticed allergic cough syrup bottles on store shelf that they are filled in equal volume and precisely packed. Wondering how that’s done? Its syrup filling machine behind all this perfect bottles.

This machine is not used only in pharmaceutical industry but its roots extend in cosmetic, veterinary, food and other industries. If you are a manufacturer or knowledge seeking person, you are on right place. This FAQ guide will help you in learning about allergic cough syrup filling machine. So, ready to explore it.

1.What is allergic cough syrup?

Allergic cough syrup-picture courtesy: hlhpharmacy.com

Allergic cough syrup is a liquid-based medication used to relieve and treat cough caused by allergy such as from pollen, dust, or other allergens; allergic triggers. It is used by both child and adults, as allergic cough can be in anyone. Allergic cough syrup is different from regular cough syrup, that is used to target throat infection, as it contains anti-allergic agents like chlorpheniramine, antihistamines or diphenhydramine. The antihistamines in this cough syrup relive symptoms such as runny nose, dry cough and other allergic symptoms by blocking histamines production.

2.What do you know about allergic cough syrup filling machine?

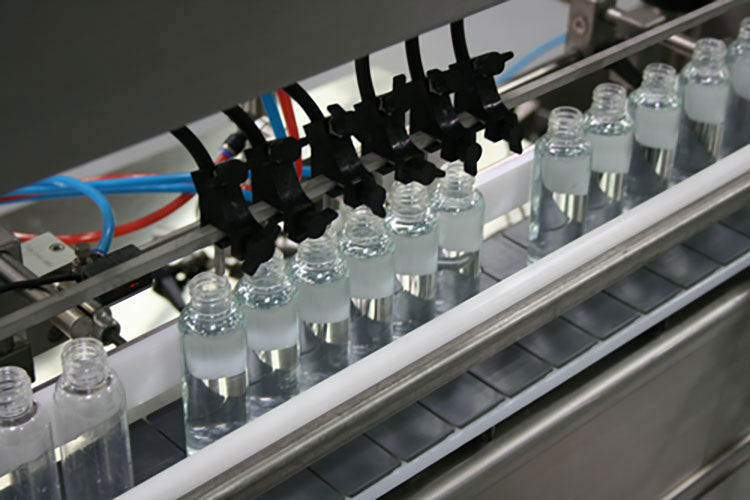

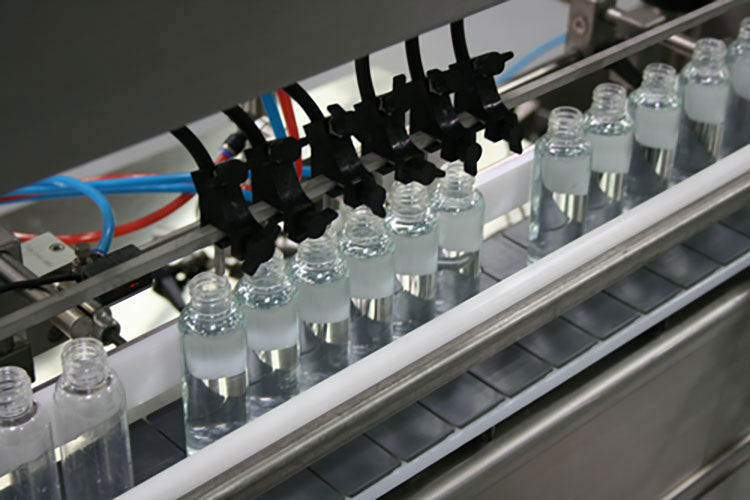

AIPAK high speed allergic cough syrup filling machine

Allergic cough syrup is in different density from thick to thin. Ever thought which machine is used to fill this diverse density syrup? Allergic cough syrup filling machine comes in hand. This pharmaceutical grade machine ensures hygienic handling of syrup, or precise filling that enhance safety and quality of allergic cough syrup. Volumetric or peristaltic filling systems, anti-drip nozzles, and automated bottle handling are the maintain features of this filling machine that supports filling of diverse containers. It meets regulatory compliance.

3.Enlist advantages of allergic cough syrup filling machine?

Have you ever wondered, how each bottle of allergic cough syrup is filled with accuracy with same volume and no mess? For a manufacturer, a precision is a core need for their products excellency. This filling machine fulfills dream of manufacturers by not only accurately fill their containers but make it safe for consumers. Let’s know advantages it provides.

Accuracy in filling

Accuracy in filling-Picture courtesy: Accutekpackagingequipment.com

One of the advantages is accurate filling or dosing of allergic cough syrup in each bottle equally. Precision in medication is important, especially in allergic medication a minor up and down in filling can be critical for patient. This machine ensures no overfilling and underfilling of this cough syrup in bottles, as this could be difficult to achieve in manual filling.

High speed production

High speed-Picture courtesy: pharmec.com

Are you looking for machine that fills bottle within no time? Don’t worry- allergic cough syrup filling machine by its automation technology can fill hundreds or thousands of bottles in less time. It can meet consumer’s demand with no compromise in quality. By feature of high-speed production, it reduces production timeline.

Versatile

Manufacturers look for a machine that meet versatile containers or products. Are you included in this category? An allergy cough syrup filling machine is one of them that handles different size, volume and forms of bottles. Different syrup viscosities can be managed.

Reduce human error

Reduce human error-picture courtesy: hilomrm.com

Less human involvement, great outcomes. There is less labor dependency in automatic allergic cough syrup filling machine. So, human involvement is less. From product loading, placement to filling and sealing, every process is automatic. Therefore, manual involvement is less. Most of the complex tasks are precisely handles by it, however, it reduces labor cost.

Reduce product loss

Reduce product loss-Picture courtesy: emcowheaton.com

Human involvement is connected to product loss. But this is not a case with this filling machine. Its structure involves volumetric filling, peristaltic pump that manage product filling like overflow, underflow or spillage. This minimizes product loss.

Integration with other machines

You can not only fill containers from allergic cough syrup but you can seal and cap them. All in one machine is available in this syrup filling machine. This increases output efficiency, no manual handling, and ensures smooth flow of product.

Safety from allergens

Moveable parts of this machine allow users to clean. Easy-to-clean parts allow you to clean components after each batch. Cross-contamination is avoidable, ensures safety from allergens.

4.Do you know application of allergic cough syrup filling machine?

By name, it seems that it is used only in pharmaceutical industry but this versatile machine has wide range of applications, use in many other industries where precision, accuracy and handling high quality product is necessary. But what exactly are these industries?

Let’s dive in its application.

Pharmaceutical industry

Pharmaceutical industry: ppmpharma.com

Allergic cough syrup filling machine is commonly used in pharmaceutical industry. Manufacturers use this machine in order to achieve accuracy, precision and accurate dosing filling of reliving syrup in bottles, where hundreds or thousands of bottles are perfectly managed. This is how pharmaceutical industries ensure every bottle with exact same volume dosage.

Nutraceutical industry

Nutraceutical industry-Picture courtesy: justdial.com

Most of the people are moving to grab natural extracted liquid minerals or vitamins or preventives allergic cough syrups. This includes sugar-free, chemical free etc. nutraceutical products. This filling machine is used in nutraceutical industry to handle diverse viscosity of nutraceutical products.

Veterinary industry

Allergic cough syrup filling machine is also applicable in veterinary industry. Same as human, animals can sick of allergy cough. But, is this filling machine, used for human syrup filling, use for pet’s allergic cough syrups filling? Yes, you don’t have to buy separate filling machines for their filling. It is used in veterinary industry due to its standard hygiene maintenance and consistent dosing.

Food industry

Food industry

In food industry, various types of liquid are handled or filled with wide range of viscosities. Thus, food industries use this filling machine. Have you ever wondered why this machine is so diverse in its application? Proper clean-in-system and movable parts allow it to be used in this industry where food-grade filling machine is necessary. It dispenses coffee syrup, medicinal beverages, honey syrups etc.

Cosmetic industry

Cosmetic industry

Wait a second, is allergic cough syrup filling machine also use in cosmetic industry? Of course, it is. Because it gently handles sensitive ingredients and components of cosmetic product and accurately dispense them in bottles, without damaging its aroma or texture.

Chemical industry

Chemical industry: memoryholevintage.com

Chemical handling requires a safe and enclosed system in order to protect the liquid solution from contact with environment. All the features it requires are engineered in this filling machine-corrosion-resistant stainless-steel body, precise filling and handling, all are suitable with chemically sensitive solutions. It dispenses cleaning agent, antiseptic liquids, or others sensitive liquids.

5.Describe structure of allergic cough syrup filling machine?

Structure of allergic cough syrup filling machine

| Components | Operation | |

| 1 | Control panel | Control panel is the main part of filling machine. Every operation of this machine is controlled by control panel like filling speed, switch on or off, sensors operation, detect error, change of program according to type of botte and viscosity etc. This user-friendly panel ensures product efficiency and accuracy with no human error. |

| 2 | Inlet | Through inlet, empty bottles enter machine for filling and capping. It ensures free-moving of bottles without jamming. It reduces downtime. |

| 3 | Body frame | Main structural body of allergic cough syrup filling machine. It supports other components of this machine. This stain less steel body ensures hygiene which is prerequisite in pharmaceutical industry. Body is resistant to corrosion; rigid, and important quality is that it is easy to clean. |

| 4 | Filling unit | Here, the main task is carried on. Guess what? Bottles are filled from allergic cough syrup. This unit ensures accurate filling. Filling unit contains pump, nozzles (anti-drip and adjustable), and tank. Nozzle can be adjusted to any type of bottle and liquid viscosity. Here, syrup is pulled from hopper, then fill into bottles through nozzle. |

| 5 | Capping unit | In capping unit, caps are placed on filled bottles. This ensures temper proof packaging to extend safety and shelf life of syrup bottles. A torque system is used to ensure tight sealing. There also cap detection system to detect caps position and faults. |

| 6 | Bottle rotary mold | You may see a proper bottle going towards filling and capping units, but how? There is bottle positioning system that stabilize bottles through different station. It prevents bottle misalignment or misplacement and hold them tightly for filling and caps placement. |

| 7 | Protection window | This window protects internal machine’s components. Operator cannot contact internal moving parts. |

6.How does allergic cough syrup filling machine work?

Allergic cough syrup filling machine operates by different step to carry out filling process professionally. Every step ensures a hygienic standard, efficient and clean handling of bottles. Following below are the steps involve in this filling machine working.

Bottle feeding

Bottle loading

The process begins with loading of bottles in machine. This is done through unscrambler which place bottles on conveyor. Then, conveyor belt load empty bottles to filling station. Bottle feeding can be done manually or automatically. This can minimize human interaction with bottles to protect from contamination.

Bottle positioning

Bottle positioning-Picture courtesy: Accutekpackagingequipment.com

Do you know how bottles are placed under filling nozzle? After bottles feeding, these are aligned under filling nozzle. Sensors detect position of bottles. The bottle holder tightly places or hold them in filling station. This step is cautiously handling because a slight misalignment can result in spillage and inaccurate filling.

Filling

Filling-Picture courtesy: adinath.com

Once bottles position is set, now is the time to fill them from allergic cough syrup. The syrup solution that is stored in tank is now transferred to filling station through pipes. Filling nozzles are inserted in bottles and through different pumps or fillers, solution is dispensed. There is volume detector that ensures equal volume dispensing of syrup.

Nozzle retraction

Nozzle retraction-Picture courtesy: justdial.com

Once bottle is filled in required volume, filling process stop and nozzle retract. There is anti-drip mechanism in automated machine. This protects dripping of syrup and protect product from waste, otherwise syrup would stick to bottle’s exterior and attract dust particles.

Filled bottles capping

Filled bottles capping

Capping process is another important step that protect filled syrup in bottles. In capping station, caps are placed on bottles. By torque process, caps are tightened. There are caps sensor that detect if caps are cracked or loosen and will reject. Capping saves filled solution from environmental factors.

Discharge

Discharge

Filled containers are moved to other machines for further process. They are moved out from filling machine through conveyor belt.

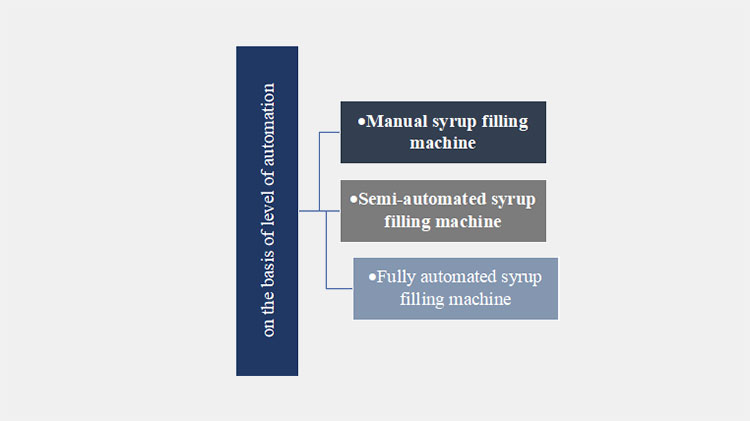

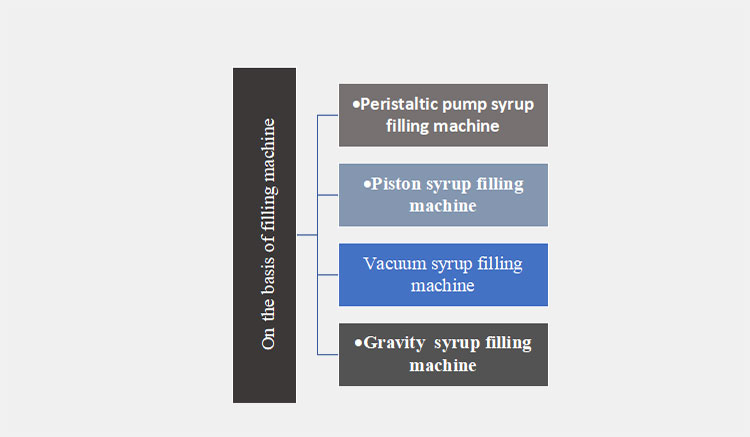

7.Are there any types of allergic cough syrup filling machine?

In market, there are various types of allergic cough syrup filling machine. It depends on type of syrup handling, and production scale. These machines are divided on the basis of level of automation and filling mechanism. Here, they are penned:

On the basis of level of automation

Followings are types of machine on the basis of level of automation.

Manual syrup filling machine

Manual syrup filling machine

This type of filling machine requires human hand in operational working. In this machine, bottles are manual loaded and most important thing about this machine is that even bottles are filled by using manual piston. It is easy to use, less cost effective, and it takes lot of time than automated ones. It’s ideal for small scale production. It is not used in pharmaceutical industry where sensitive materials are handles and have to meet large demand with accuracy and by maintaining hygiene.

Semi-automated syrup filling machine

Semi-automated syrup filling machine-Picture courtesy: sunflexorg.com

This type of machine is ideal for medium-scale production. As from its name, you can guess its operation. Operator loaded bottles in machine where filling is done by machine. It provides accuracy better than manual type of machine. But still, there is human involvement, and feeding, filling and other process can get contaminated and pose errors.

Fully automated syrup filling machine

Fully automated syrup filling machine-Picture courtesy: lodhapharma.com

It is ideal for large scale production. Every step is controlled by sensors or detectors and each is automatically carried out, and require experts to handle it. It ensures accuracy, precision and hygiene quality that make it suitable for pharmaceutical industry. There is no manual intervention so human contact is low. It is expensive than above two but gives best output.

On basis of filling mechanism

Followings are the types of allergic cough syrup filling machine on the basis of filling mechanism.

Peristaltic pump syrup filling machine

Peristaltic pump syrup filling machine

This machine is ideal for sterile handling of product, so ideal for pharmaceutical grade products. It uses a roller that pushes syrup solution through tube into bottle. It gives a germs-free, accurate and precise result. This filling machine is best for foamy syrups. Easy-to cleans part, only need tubes to be replace.

Piston syrup filling machine

Piston syrup filling machine

For thick syrup, you can use piston syrup filling machine because it is best suited with thick syrup filling. It uses piston that pushes high viscous liquid from tank to bottles. It gives accurate result. For accurate and contamination free filling, regular cleaning and maintenance is required. Exact volume of syrup is dispensed in each bottle. Curious that how? By adjusting length of a piston.

Vacuum syrup filling machine

Vacuum syrup filling machine

This is not suited to thick syrup. Glass bottles are mostly filled by using vacuum syrup filling machine because it is ideal for glass bottles where uniform fill level matters. Do you know how does it work? Well, it uses vacuum pressure for dispensing solution in bottles. No need to worried about dripping-There is anti-drip system to preserve your product appearance and cost.

Gravity syrup filling machine

Gravity syrup filling machine-picture courtesy: liquidpackagingsolution.com

Ever think how thin liquid would be fill? For this, gravity syrup filling machine is used. It uses gravity by free-flowing of syrup. For better operation, thin liquid should be used. This cost-effective machine is not ideal for thick solutions but use for thin pharmaceutical products.

8.What type of containers can be handled by allergic cough syrup filling machine?

When you visit store, you may see different size and shape of allergic cough syrup containers. What is behind different containers filling? It’s allergic cough syrup filling machine to meet medical standard. To know type of containers it handles are following below.

Glass bottles

Glass bottle-picture courtesy: vialbottle.com

Different sensitive products are handled in different industries. This machine is used to fill these sensitive materials in glass amber bottles which provide non-reactive and excellent non chemical environment to maintain their potency and effectiveness. As these bottles are sensitive, so there are sensors to protect them from cracks.

Plastic bottles

Plastic bottles-Picture courtesy: jskplast.com

Various size of plastic bottles is handled by this filling machine. These PET made plastic bottles are commonly used in pharmaceutical industry because they are cost effective, light weighted and chemical resistance. These plastic bottles are available in various shapes from round, oval to flat.

Bulk containers

Bulk containers-Picture courtesy: esboisesdamelie.com

This filling machine can also handle bulk containers. These bulk containers are used for institutional supply or clinic. A hygiene, dosing precision and product integrity are not compromised while handling bulk containers.

9.How to maintain allergic cough syrup filling machine?

For proper and efficient function, maintenance of allergic cough syrup filling machine is necessary. Proper maintenance extends life span of machine parts, and safe product quality. Hence, for high-precision performance, or consistent accuracy, following practices should be keep in mind.

Lubrication

Lubrication-Picture courtesy: plantengineering.com

Lubricated components of machine achieve great output. Lubricate working parts of this machine such as piston, pump, conveyors or others. This will minimize wear and tear problem and will smoothly work. It should be kept in mind that always use food grade or pharmaceutical grade lubrication oil. Avoid daily lubrication, do it once a week.

Software check

Software check

As this filling machine is automated. Whole system is controlled by software. Check for software errors, if any, sensor feedback accuracy etc. Update software to latest version. This should be done once a year.

Cleaning

Cleaning-Picture courtesy: galdi.com

For germs-free filling, cleaning is important maintenance practice. What does cleaning include here? Cleaning in allergic cough syrup filling machine includes dispensing nozzle, pipeline, tank etc. Always use sterile water or pharmaceutical grade cleaning agents. Cleaning should be done on daily basis as nozzle clogging or residual syrup can result in microbial growth, and this can compromise your whole product batch.

Calibration check

Another important practice is calibration check. As this machine is used in pharmaceutical industry and handle allergic cough syrup where accurate dosage is important. A small deviation can shatter consumer’s trust and compromise product safety. However, calibration check means to adjust filling components and mechanism. This allows correct amount of syrup in each container.

Complete documentation

Complete documentation

You should always keep thorough document of operational activity and calibration. It is a major requirement to maintain this filling machine. It ensures accountability, since any inconsistency in filling process must be accountable and traceable. FDA audit can check this document for quality betterment.

10.How to troubleshoot allergic cough syrup filling machine?

As you have read above that proper maintenance is necessary to reduce down time. Still, you can face some of the problems. But you can troubleshoot them. In this defense mechanism, first know the issue and then solve it. Let’s uncover them.

Dripping after filling

Dripping after filling

| Issue | Troubleshooting |

| Ever happened syrup dripping from nozzle while filling? This is common issue. It can be due to worn or cracked nozzle and loose connection. This can be a big product lose for industry. | For solving this issue, first, you should inspect the nozzle area to analyze the main issue with filling. Tighten up nozzles if loose. Install anti- drip nozzle so no product lose will be faced. |

Inaccurate filling

Inaccurate filling

| Issue | Troubleshooting |

| Filling nozzle may be blocked that results in inconsistent filling. Or air pressure may be changed or malfunction in filling pump. | To resolve this issue, you should follow: check for a filling pumps cracks or blockage. Also adjust air pressure and filling speed inside filler pump. Carry out calibration check for better filling mechanism. |

Incorrect position of bottles

Incorrect position of bottle-picture courtesy: landpack.com

| Issue | Troubleshooting |

| You might have experience incorrect position of bottles. An issue can be with conveyor belt may be misaligned. Sensors responsible for bottles positioning may contribute to this issue. | The troubleshoot for these problems are to adjust conveyor and sensors detecting orientation of bottles. |

Forming after filling

Forming after filling-Picture courtesy: suntermachinery.com

| Issue | Troubleshooting |

| Have you seen form building after filling? This issue can be due to over speed of filling. It results in overflow and cost product lost. Improper nozzle position also plays their role in spillage of product. | Use filling nozzle according to type of allergic cough syrup. Reduce filling speed so product settles down at bottom properly. |

Conclusion

To conclude this FAQ guide, it must be noted that allergic cough is caused by allergens. For this allergic cough syrup is used. This syrup is accurately filled in bottle by syrup filling machine. Different components of this machine work together to manage the operation. Along with this, different types of syrup filling machines are available from manual to automated, can buy according to your budget. Notable feature is that it can be use in other industries for filling bottles like in cosmetic or food industry. If you have any query, contact with us. Thanks!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours