Protein Manufacturing: The Complete FAQ Guide In 2025

Isn’t amazing to know how protein acts as a booster of your life? Just think about it, the cell which is a fundamental and crucial unit of life is made up of protein. If no protein; no life.

So, in this case, you always need to have external protein sources, like supplements in your diet to attain more improved functionality. That’s why, various manufacturing companies worldwide have focused on protein manufacturing and this business is growing leap and bound with enhancing the physiological processes and quality of life. Come on reader, let's read about basic to advanced facts related to protein manufacturing in this article.

1.What is protein manufacturing?

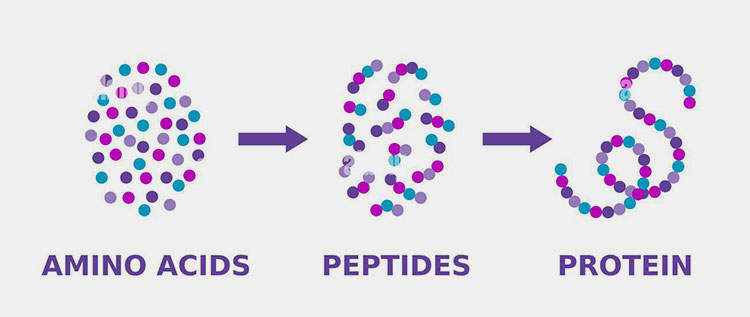

Protein Manufacturing

Protein manufacturing is the process of producing protein to fulfill the essential amino acids required for protein balance. You must be clear in mind that proteins are actually made up of amino acids and hence known as building blocks. So, when you combine amino acids, it forms a peptide chain that is twisted in various shapes to form a particular protein structure. Remember each structure protein is meant for a specific function in your physiological system.

2.How does protein manufacturing benefit you?

Significance Of Consuming Protein

Protein manufacturing is a beneficial solution not only for consumers but also for people who are in business or manufacturing sectors. We have described the reasons just right below:

| Reliable Way To Meet Global Needs

Protein Products- Picture Courtesy: Open Access Govt |

Today, awareness related to improving well-being is growing. Every customer finds the benefits of protein and grabs the product. Therefore, its demand and requirements are rising. Protein manufacturing is the solution that ensures business expansion locally and internationally with extensive demand. |

| Nutritious Addition to Your Health

Nutritious Addition To Your Health Supplements- Picture Courtesy: Dr Johnla Puma |

Whether kids, young, old people, or vegans, protein manufacturing offers an easy and valuable product as a supplement. You just need to take its suitable quantity and prepare the solution, whether in milk or water to energize your body. It is full of nutrition and useful ingredients that promise you healthy physiology by fulfilling your daily protein requirements. |

| Formulation Related to User Preferences

User Preferences- Picture Courtesy: Health |

Protein manufacturing is the broad-spectrum process that allows the making of vegan protein, milk protein, sport-related protein, enzyme protein, etc. in various flavors, colors, textures, mouthfeel, sugar-free forms, and so much more. It's all about your needs! Your choice is always considered as the manufacturer’s priority to produce a tailored protein formulation. |

| Convenient to Use in Fast Pace Routines

Good Option For Busy Routines- The Prolotherapy Clinic |

With protein manufacturing, a quick means of consuming essential proteins is created. Nowadays, everyone is busy in their lives, so they can’t take a breather to have meals. This leads to missing vital amino acids in the diet. Thus, people find it easy to quickly solution either in the form of injectables, drinking, or consuming solid dosage formulation needed for the well-being of their bodies. |

| Keep You Full and Controls Blood Sugar

Keep You Full |

Tired of feeling hungry or taking constant snacks? Protein manufacturing provides you with a product for reducing or managing your weight. With a simple mixing of protein powders in any drink, you can lower your hunger pangs, sugar cravings, and even mindless snacking. As it keeps you full for hours. Moreover, protein manufacturing is needed for sugar lowering medication using biotechnology pathways such as insulin, semaglutide, etc. |

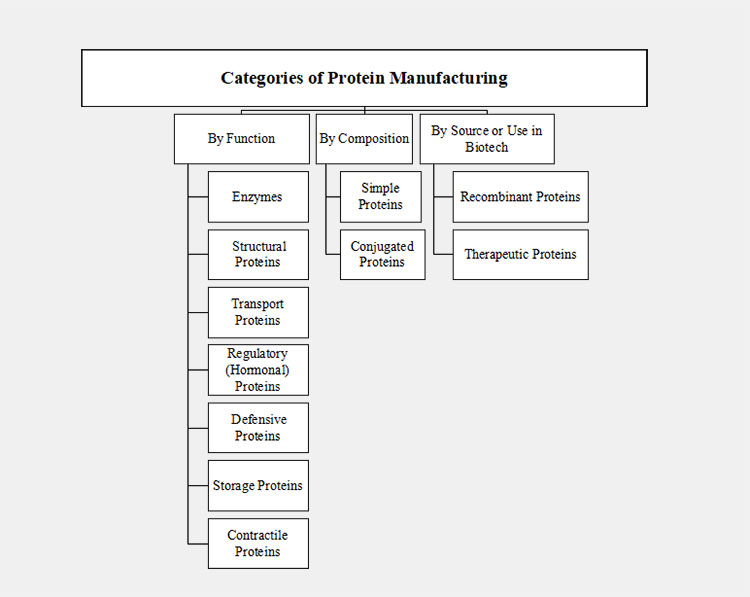

3.What are major categories of protein manufacturing?

Categories of protein manufacturing

Functional Protein Manufacturing

This is the type of protein manufacturing where protein is responsible for improving the physiological function of your body. For example:

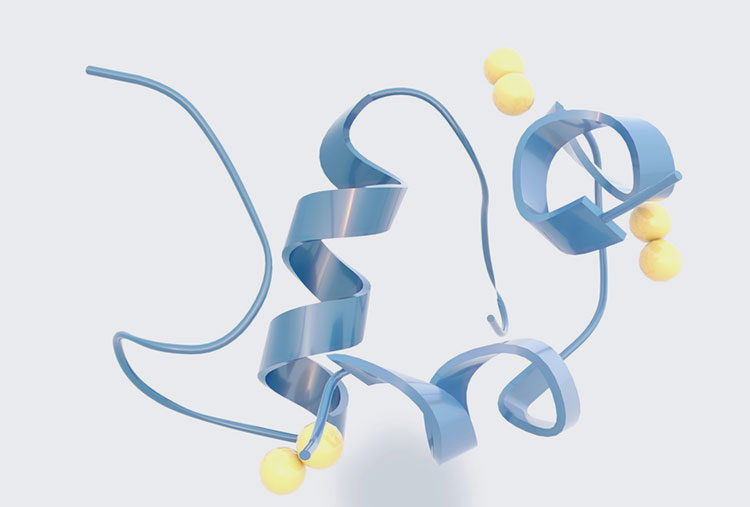

Enzyme/Globular Protein Manufacturing

Enzyme protein manufacturing

Such a type of protein is mainly responsible for aiding and catalyzing inside chemical and enzymatic action of your body. For example, chymotrypsin, which is digestive enzyme secreted by pancreas for digestion of food.

Structural/Fibrous Protein Manufacturing

Collagen Structural Protein Manufacturing

This type of protein is manufactured to improve structural integrity for your body. For example: hair, nail, skin, etc. Hence the overall framework can be improved and strengthened. In the market, collagen injectables, injectables and powders are available which is a common example of protein manufacturing.

Transport Protein Manufacturing

Transport Protein Manufacturing- Picture courtesy: Merit Pharmaceutical

In your body, your blood molecules act as a transporter of nutrients, oxygen, and essential ions. In this way, biopharmaceutical sciences can boost up the process by transport protein manufacturing and offer formulation in the form of either solid dosage formulation, liquid, or injectables. For example, iron, and related supplements.

Regulatory (Hormonal) Protein Manufacturing

This is commonly used procedure for protein manufacturing to regulate the physiological hormonal secretion of your body. For example: insulin, glucagon, and other

Defensive Protein Manufacturing

Your body may be prone to infection when immunity is weak. In this way, the defensive protein manufacturing is useful which is responsible for manufacturing of various antibodies and vaccines to keep your body safe. The common example of defensive protein manufacturing are immunoglobins, antitoxins, vaccines, etc.

Storage Protein Manufacturing

Storage protein manufacturing

There are various kinds of protein that are essential to consume regularly to maintain body coordination and functions. The storage protein manufacturing is based on preparation on essential amino acids, various trace elements etc. which is critically important for your body. For example: plant based and animal-based protein sources.

Contractile/Membrane Protein Manufacturing

Contractile Protein Manufacturing

The contractile protein manufacturing is required to improve muscular tone of your body. This is mainly linked to therapeutic and OTC protein intake such as protein shakes, juices and medications like myosin.

By Composition of Protein Manufacturing

This is a type of protein manufacturing based on composition of amino acids. For example:

Simple Protein Manufacturing

Simple Protein Manufacturing

This is composed of only amino acid chain in the formulation. It doesn’t have any foreign involvement of substances. For example, Bovine Serum Albumin or BSA, HSA, etc.

Conjugated Protein Manufacturing

Conjugated Protein Manufacturing

This type of protein manufacturing is based on involvement of pure protein and prosthetic groups such as trace elements etc. to make them functionally important. For example, iron formulations.

Use in Biotechnology

This type of protein manufacturing indicates the source through which protein are produced for example:

Recombinant Protein Manufacturing

Recombinant Protein Manufacturing- Picture courtesy: Wikipedia

This is the way where proteins are produced using genetic engineering. It means protein genes are inoculated into the host cell that rapidly multiplies and produces number of proteins. For example, insulin is formed by fast multiplication of E. coli using genetic engineering pathway.

Therapeutic Protein Manufacturing

Therapeutic Protein Manufacturing- Picture courtesy: Science News

They are mainly prepared using pharmaceutical fields and implemented for various ailments as a form of medication such as mono-clonal antibody, chemotherapeutic agents etc.

4.What are the key ingredients of protein manufacturing?

Are you curious about the key ingredients of protein manufacturing? Generally, these ingredients are divided into two major categories, which are primary protein sources and additional ingredients. As you already know all about protein sources by reading the above question, now we’re explaining additional ingredients.

Sources

People with dietary restrictions often want to know what is their protein supplement source. Well, to inform you and other individuals, proteins are created from diverse sources, but they’re categorized into two main classes, which are:

Animal-Based Proteins Source

Animal- Based Proteins- Picture Courtesy: Bicycling

For manufacturing animal-based proteins, usually dairy products are used. In some cases, egg, beef, or, animal tissues, such as skin, bones, and cartilage are also utilized. Here are some of the major animal-based protein sources:

| Whey Protein | One of the most favored protein sources for supplement production. Whey is obtained as a byproduct during cheese manufacturing. When you make cheese, you’ll curdle milk, resulting in the formation of solid curds and liquid whey. |

| Casein Protein | Yes, you make this protein from milk. This protein is present in solid curds created during cheese manufacturing. |

Plant-Based Proteins Sources

Plant- Based Protein Manufacturing- Picture Courtesy: Digital Sages

Indeed, manufacturers create supplements from plant-based sources for vegan, vegetarian, or lactose-intolerant people. Often, they’ve essential amino acids to fill the nutritional gap in these folks. Some common plant-based proteins are:

| Pea Protein | This protein is well-liked by the customers because it is a complete protein in itself. Which means that it has every one of the 9 vital amino acids. Also, very easy to digest and budget-friendly. |

| Brown Rice Protein | Although it is not a complete protein, it has a low amount of lysine. You’ll often find it in plant-based protein blends like with pea proteins. |

| Soy Protein | Well-received by manufacturers and users alike because of its ease of availability and smooth consistency. However, it can cause allergies in some consumers. |

| Hemp Protein | Not just a protein source but also comes with beneficial omega-3 and omega-6 fatty acids and fibers. |

Ingredients For Powders & Liquids Protein Manufacturing

The ingredients for oral protein manufacturing are:

Protein Manufacturing for Liquids

| Sweeteners | Added to make protein formulation sweet. They can be natural or artificial substances, for example, aspartame, sucralose, stevia, etc. |

| Flavorings | Their function is to enhance the palatability of proteins and to make proteins more appealing to customers. |

| Gums | Also known by the name of thickeners. You may incorporate natural thickening agents, such as xanthan, guar, or cellulose gum to provide the required viscosity to proteins, especially when mixed. These agents also improve mouthfeel and prevent protein agglomeration. |

| Emulsifiers | Protein and other ingredients tend to separate after some time. That’s why, to have a smooth protein blend and minimize separation of ingredients after mixing, you’ve emulsifiers in your protein preparation. |

| Anti caking agent | These substances, like silicon dioxide, prevent powder clumping. |

| Vitamins, Minerals, and Free-Form Amino Acids | Last but not least, different micronutrients, for example, vitamins, minerals, and free-form amino acids (extra Branched-Chain Amino Acids (BCAAs) or L-Glutamine) are added in protein supplements to offer additional nutrition to consumers. |

Ingredients For Injectables Protein Manufacturing

Injectables Protein Manufacturing- Picture Courtesy: Lyophilization Core

Apart from active sources the inactive ingredient of injectables protein manufacturing are:

| Preservatives | To have stable formulation of injectables proteins, the preservatives are added during processing that doesn’t affect the activity of the product. For example, benzoic acid, paraben etc. |

| Buffer | To avoid irritation when administering systemic circulation, the buffering agent are added to the injectables for example, phosphate buffer, sodium biphosphate, sodium acetate, etc. |

| Water | For dilution and reconstitution, purified water is used. The water must be obtained from treatments to avoid chances of contamination and the entrance of any foreign particles |

5.What are the basic steps of protein manufacturing?

Steps of Protein Manufacturing- Picture Courtesy: Wicked Protein

Before your protein supplement is packed into protective packaging, it goes through several multi-step processes, each responsible for transforming whole plant-based or dairy-based food materials into dry powders for your shakes.

Let’s discuss the complete order of these steps in the following section:

Starting Material Selection and Preparation

| Selection | Typically, your protein manufacturing on a large scale begins with the selection and preparation of source material. Depending upon your consumer demand, you either select milk-based proteins, plant-based proteins, or both. |

| Pretreatment | Now that you’ve picked out your desired protein source, you’ll process these proteins. For instance, for dairy-based proteins, you’ll collect milk, assess its quality, pasteurize it, and then separate it into casein or whey. In the case of plant-based proteins, you’ll harvest plants, clean them, and grind them into fine powder. |

Extraction

Protein Manufacturing- Picture courtesy: BSC

Believe it or not, this step has a central place in protein manufacturing. Why? Because at this stage, your favored protein is isolated from other nutrients, for instance, carbohydrates, fats, fibers, and other micronutrients. However, it is worth noting that based on the source material, this step is carried out in different ways:

| Filtration | When you’re creating whey protein powder, you’ve to use specialized membranes having diverse pore sizes to pass liquid whey. With the help of these filtration procedures, you can easily extract protein molecules from small compounds, such as water, lactose, or minerals. |

| Chromatography | In this method, various columns, especially ion exchange chromatography are used to separate out protein molecules from the solution. At this stage, resins in the column having ionic compounds bind with proteins, while other materials in the solution wash away with liquid. After that, you use buffers to elute bound proteins. |

| Wet Fractionation | This method is mostly employed for isolating plant-based proteins. At the start, the ground plant powder is mixed with water. Then mechanical methods, like centrifugation to fraction proteins and other compounds. You can also use different buffers and enzymes to extract soluble proteins from insoluble fibers and starch. |

Purification

Protein Purification Process- Picture Courtesy: Creative Bio Structure

After your core extraction or isolation process, you’ll increase the amount of protein in the solution by evaporating surplus water and non-protein materials. In this way, you can attain the required purity level for your end product.

Drying

Drying Process Of Protein Manufacturing-Picture Courtesy: Freez Dry Protein

Now you’ll subject your concentrated protein liquid to a dryer machine that is usually a spray dryer. Thinking about how protein is converted into dry powder? First, the protein solution is atomized into fine mist by passing it through the nozzle. In the drying chamber, this fine spray comes in contact with hot air, resulting in the evaporation of water.

Blending

Blending Process- Picture Courtesy: Dairy Products Nz

It’s time for protein powder formulation. Guess what? This step involves the mixing of pure proteins with various auxiliary ingredients, for example, flavoring agents, sweeteners, texture enhancers, and, others.

Formulation and Filling

Recyclable Protein Packaging Bags- Picture Courtesy: Australian Sports

Now that your product is prepared. In case of liquid formulation, they are filled in vials, powders are filled in an enclose it in durable, airtight, waterproof, and long-lasting packaging. For capsules, the capsule filling machine is used to dispense the volume of protein and is packed in bottles or strip packaging. In case of tablet, a tablet press is used to produce firm and stable tablet formulation.

Labeling

Labeling Of Protein Manufacturing- Picture Courtesy: JR Medical

In most cases, protein packaging comes in pre-printed forms but you’ve to apply labels on some containers to communicate product information to users.

Cartoning

Cartoning Pack- Picture courtesy: RAW Nutrition

Finally, the protein product packaging is secured in durable carton boxes at the cartoning step. Boxes are formed using cardboard sheets at this stage and then are loaded with packaging. And sealed with glues or tapes in the last.

6.What are the essential machineries for protein manufacturing?

It is hardly surprising that multitudes of machines are responsible for carrying out protein manufacturing. Each one is crucial at various stages of operation. However, you might not know this, but you can use a different set of machinery depending upon your source material and the characteristics of the final product. For your information, some important machines are penned below:

Initial Processing

| Mills

AIPAK Pharmaceutical Pulverizer |

You might know this machine by the terms- grinder or pulverizer. When you’re making plant protein powders, you’ll use them for grinding or crushing your plant material into fine powder. In this way, you can increase the surface area of the plant for isolating protein. |

| Centrifuge

Centrifuge Machine- Picture Courtesy: HERMIL |

Think of it as a machine that spins at higher acceleration. This spinning motion is vital in the generation of centrifugal forces that in turn separate heavier components from lighter materials based on their densities.

It fractionates molecules with larger-weight ones settling at the bottom and lighter ones being present in the upper layers. Typically, you can employ this system to separate milk components in protein manufacturing. |

Extraction and Purification

| Membrane Filtration System

Picture Courtesy: GEA |

Without a doubt, this system is the most significant one when you’re extracting your protein from other components and impurities. Using it guarantees you a high purity of protein isolates. How does it work? Well, there is a semi-permeable membrane with a specific aperture size in this machine that allows you to purify proteins of a particular size.

Different systems of filtration systems, such as microfiltration, ultrafiltration, and nanofiltration exist to remove larger molecules, separate finer particles, and concentrate your proteins. |

| Chromatography Column

Picture Courtesy: Cytiva |

Ever heard of a chromatography column? Its specific type- ion exchange chromatography is employed to isolate proteins, especially whey.

This machine consists of large columns containing solid matrices or resins with either positively or negatively charged groups based on the charges on the protein you’re purifying. Proteins in the sample interact with these functional groups, resulting in their binding, while the rest of the solution flows down the column. |

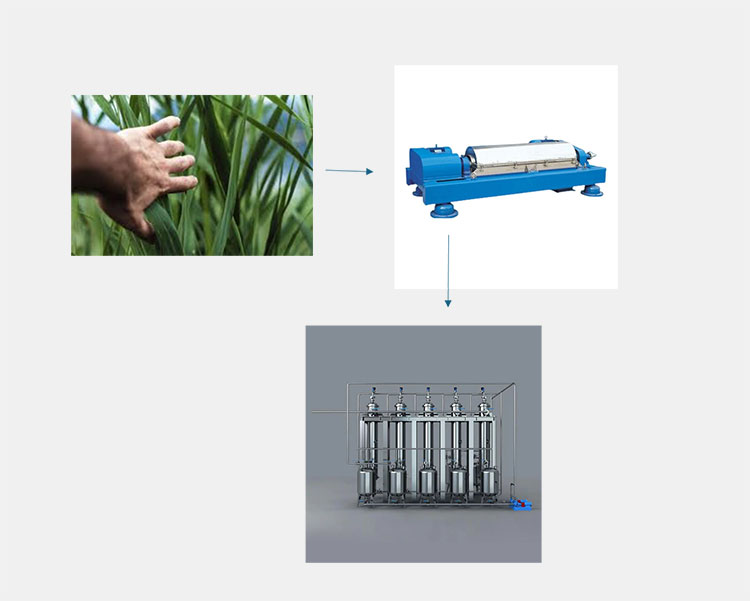

Centrifuge Filtration

AIPAK Engineering centrifuge filtration machine |

For plant-based protein manufacturing the centrifuge filtration unit is used. This is mainly composed of a conical drum, screw pusher and various bearing base that helps in the clarification, and dehydration of suspension effectively. |

| Plant Extraction Supporting Membrane Separation Equipment

AIPAK Engineering Plant Extraction Unit |

You can selectively obtain the specific components using plant extraction supporting membrane machine which can separate the components by using membrane and allow purified concentrated mixture. |

Spray Dryer

AIPAK Engineering Centrifugal Spray Dryer

Centrifugal spray dryer is one of the most frequently utilized devices for changing liquid proteins into dry powder. Often has atomizing nozzles, a drying chamber, a cyclone separator, and solvent recovery units. After the formation of a fine spray of liquid protein, water is evaporated by exposure to hot air. This leaves behind dry protein powder.

Filling and Packaging Machines

You may have diverse packaging machines on the basis of what container you’re packing your protein product in. The most common types are:

| Vial Filling Line

AIPAK Engineering Vial Filling Line |

In case of filling hormonal proteins, you will need a vial filling line which is mainly composed of set of machines included, washing, sterilization filling and sealing machine. |

| Syringe Protein Filling Line

AIPAK Engineering syringe filling production line |

Protein formultion like insulin, heparin, hyaluronic acids etc are mainly filled by syringe filling production line. This machine performs aseptic filling of various vaccines, antibodies and small molecular formulations. You can find them in various pharmaceuticals, biotechnological, and neutraceutical companies.

The entire production line works automatically to bring accurate filling in a sterile way. |

| Bottle/Jar Filling Machine

AIPAK Automatic Powder Filling Machine |

For filling your bottles or jars, a bottle/jar filling machine is found in protein manufacturing. Mostly, you’ll see that this device comes with auger fillers. They’re conical-shaped devices that accurately deposit a fixed quantity of protein powder in containers. |

| Vertical Form Fill and Seal Machine

|

As you might have guessed by reading its name, this machine is known for its vertical configuration operation. Yes, it fills containers in upside upside-down manner. It is a popular machine for packaging pouches. It transforms a film roll into the pouch, then fills this pouch, and finally, seals it. |

| Premade Pouch Packaging Machine

AIPAK Rotary Stand Up Pouch Vacuum Premade Pouch Filling Machine |

For premade pouches, you generally utilize premade pouch filling machine. No film roll is required by this machine, however, you’ve to load premade empty bags on the equipment magazine. This is because it processes already-made bags and hence, quickly packs pouches. |

Labeling Machine

AIPAK Labeling Machine

A labeling machine is vital when it comes to informing users about products. In most instances, it sticks pre-glued labels on jars or bottles. Hot-melt glue or wet glue is also utilized by this system to apply labels on containers.

Cartoning Machine

AIPAK Cartoner

Ever wondered how protein powder packaging gets into cartons? For this, you’ve got a cartoning machine in your protein manufacturing. Using carton erecting, folding, product picking, and loading components, this equipment speedily and securely dispenses your product packaging into boxes.

7.How is the protein manufacturing flavored or sweetened?

Flavored Protein- Picture Courtesy: Amai Proteins

It may come as a surprise that your raw proteins often have a bitter, bland, or, unsavory taste. However, with specialized ingredients, manufacturers make palatable and flavorsome for their consumers. Here are some frequent ingredients that add to flavorful or sweetened touch to protein powders:

| Natural Flavor Extracts | Yes, you can obtain these flavoring agents from real food sources present in nature. Many natural flavor extracts, such as vanilla beans, cocoa beans, strawberries, coffee, etc. are used in protein manufacturing. |

| Artificial Flavors | Sometimes, manufacturers prefer to use artificial flavors, as they’re more stable and less expensive. These agents taste identical to natural ones. |

| Flavor Masking Compounds | As you might know, proteins, especially the ones acquired from plants naturally taste off, like earthy or bitter. So, flavor masking agents are common in protein manufacturing because they either hide or neutralize these unpleasant tastes. |

| Sweetening Agents | For making clean-label protein products, natural sweeteners are the first choice of manufacturers. They often have an intense sweet taste and may include stevia extract, sugar alcohols, and, in rare cases, dextrose or fructose. |

8.What is the storage condition for protein manufacturing?

Storage of Protein Powder

Keeping protein at appropriate conditions after manufacturing is essential in extending its expiry date. And if you neglect it, you may have product degradation or microbial growth on your hands.

Temperature

Protein Products- Picture Courtesy: Utah Facial Plastic

Remember to place your protein powders at below 25°C or 77°F. Every so often, the optimal temperature range for their storage is around 18-21°C (64-70°F). In some cases, even cooler storage temperatures are needed for very sensitive products.

Humidity

Protein Powder Clumps Humidity- Picture Courtesy:Vegan Foundry

Clumping, caking, or, microbial growth happens in protein powder when it absorbs moisture from surroundings. To prevent this issue, the relative humidity of the storage place should be below 65%.

Light

Sensitive Insulin Protein- Picture Courtesy:The Brighter Side

Don’t expose your powder to direct sunlight or even artificial lights for extended periods. Because it breaks down sensitive ingredients, such as vitamins, and promotes reactivity of nutrients with oxygen, leading to their ruining.

Air Quality

Protein Powder Harsh Smell- Picture Courtesy: Feast And Phrase

You must have good circulation of filtered air in storage areas. Also, there should be no harsh-smelling substances in or near the storage space, because proteins can absorb odors from the air.

9.How long is protein effective after protein manufacturing?

Efficasy- picture courtesy: Nutrigr8

When you say protein effectiveness, it normally means its safety of consumption after manufacturing and its nutritional strength. It is good to know for how long your protein is best after its manufacturing. This best-by or use-by date is always mentioned on the back of the container.

However, generally speaking, this expiration date is around 1 to 2 years after protein manufacturing. But it is worth mentioning that additives, stabilizers, and, sometimes, preservatives like salts are added to prolong the usage period of protein powders up to 2 years.

In addition, some studies have found that whey protein will have optimal nutritional quality and taste for 9 to 19 months. Whereas, plant-based proteins in general have more longer shelf-life that is around 2 years.

10.What things should you consider when opting for protein manufacturing?

Picture courtesy:

If you’re planning to start your own protein manufacturing, you would be searching for some tips and suggestions as to how you should proceed. Well, look no further because we’ve rounded up some must-know tips just for you:

Define Your Target Audience

Consultants To Reach Their Target Audience- Picture Courtesy:Mbo Partners

First of all, you should do some planning and research, for example, define who are your consumers. Are they athletes, health-minded individuals, opting for weight loss, seniors, or children? You should think about whether you’ll provide cleaner ingredients, specific blends, or inexpensive formulas.

Choose Your Protein Source

Right source- Picture Courtesy:Et Protein

Consider this tip as the foundation of your protein manufacturing. Not every protein is manufactured in the same way, so choose whether you’ll go for whey or casein, pea or hemp.

Raw Material and Ingredient Selection

Ingredients And Pure Raw Material- Picture Courtesy: Soy protein cn

When sourcing your ingredients, always plan ahead about how you’ll ensure their purity, quality, and, cost-effectivity. Also, take into account the reliability of your ingredient supplier, his certifications, and his customer reviews.

Design a Suitable Facility

AIPAK Engineering Cleanroom Floor

Always aim for facility design that provides enough space for smooth workflow and ease of cleaning. Your facility layout should support the unidirectional flow of materials with starting materials going in and finished proteins coming out. Implement aseptic, hygienic, good manufacturing practices protocols in your protein manufacturing system.

Buy Best-Quality Equipment

Reliable And Service Support System- Picture Courtesy: DMoose

Once you’ve designed your production floor, now it’s time to move to purchasing equipment. For this, look for an experienced manufacturer with a solid reputation, positive customer feedback, and reliable after-sale services, like warranty coverage, repair support, or installation assistance.

Conclusion

Now it’s time to conclude your FAQ guide about protein manufacturing. From choosing the suitable protein source to boxing and wrapping your final products, every step has its own importance when you’re aiming to create a clean, nutritious, mixable, and, appetizing product. Remember you can carry out protein manufacturing seamlessly as long as you’ve high-quality ingredient materials and state-of-the-art machines. And you can only get top-quality machines from experienced manufacturers, such as AIPAK Engineering. So, contact us now to buy equipment related to protein manufacturing. We’re here to fulfill your manufacturing dreams.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours