Growth Hormone Vial: The Complete FAQ Guide In 2025

Ever wondered about how so tiny growth hormone vial pack some power-punch advantages? You can certainly see that it is quite small and sealed and at first glance doesn’t look much. However, if you take the time to learn about its features, this small vial holds the most potent formulation that has a role in healing your tissues, growing your muscles, and improving your energy levels, and overall health.

But how do you know how these formulations are prepared? What is the right way to store them? How can you obtain maximum benefit from every dose? These queries often arise in your mind if you’re a researcher, a pharmaceutical manufacturer, or just someone interested in learning about the intricacies of the growth hormone vial.

In this blog post, we’ll answer your each and every query related to the growth hormone vial. So, let’s get your reading glasses on because you’re here for a knowledgeable ride.

1.What is growth hormone? What is its function?

Growth Hormone – Picture Courtesy: Verywellhealth

In simple words, it is a hormone that boosts the growth and development of the body. It is a misconception that you don’t need it after your height stops increasing. In addition to, promoting height, especially in children, it also has a role in optimizing your metabolism.

You can also call it by term somatotrophin. It is a naturally produced hormone in the human body and is created in the master gland- the pituitary gland. People know it due to its growth-stimulating effects on bones and cartilage.

However, it induces the growth of almost every tissue and organ in the body and aids in keeping normal body structure by controlling fats, muscles, tissues, and bones, and regulates your blood sugar levels.

2.What is meant by a growth hormone vial?

Growth Hormone Vial – Picture Courtesy: Food Poisoning News

An injection of synthetic growth hormone is prescribed to children and adults to improve body shape and mass, restore energy levels, and boost metabolism. It is especially recommended for children to treat short stature, poor growth, or deficiency (insufficiency) of natural growth hormones.

Whereas a growth hormone vial usually refers to a tiny, sterile, closed cylindrical vessel especially, made to hold liquid medications like synthetic growth hormone for parenteral administration. It is formed from glass or medical-grade plastic.

This vial often encloses lyophilized (freeze-dried) powder that is reconstituted with sterile water for injection before dispensing.

3.Why is the growth hormone vial so popular in today’s society?

Nowadays, you're observing a trend where individuals are increasingly purchasing growth hormones in vial form, as prescribed by their doctors. Ever wondered why? It is because of the diverse uses and benefits of growth hormone. If you're curious about the increasing popularity of growth hormone vials, the reasons are detailed below:

Serious Growth and Development Problems

Serious Growth and Development Problems- Picture courtesy: Kenton Bruice, MD

One of the main reasons of growth hormone vials seem like flying off the shelves is because of health awareness. Many individuals and children are seeking treatment for their growth hormone deficiencies. Doctors advise this therapy to gain height, treat metabolic imbalance, and improve overall development in patients.

Increasing Muscle Mass

Increasing Muscle Mass- Picture courtesy: North Cyprus IVF

It is a well-known fact that growth hormone has an integral part in boosting muscle growth and density. Therefore, many athletes and fitness-conscious individuals buy the growth hormone vial off-label to build their muscle mass and improve their physical performance. It helps in quicker recovery post-exercise and also encourages fat loss.

Anti-Aging Treatment

Anti-Aging Treatment- Picture courtesy: Metro Hospital

Despite lacking some strong scientific evidence, it is usually advertised that growth hormone has anti-aging properties. Consequently, numerous people purchase the growth hormone vial in the hope of combating age-related physiological changes, for example, recovering skin elasticity, energy levels, and vitality. Besides this, it is a major component of hormone replacement therapy in anti-aging clinics.

Dosing Accuracy and Administration Ease

Dosing Accuracy and Administration Ease- Picture courtesy: Invigor Medical

With a growth hormone vial, you’ll have accuracy in dosing measurement and you’ll easily customize administration according to the needs of patients, which is impossible with pills. It also allows nursing staff to dispense repeated dosing from the same vials without contamination.

4.What are various types of growth hormone vials?

As you already know growth hormone vials come in various forms. It is classified into various kinds depending upon their storage and dosing volume. Here we’re penning the types of growth hormone vials based on their dosing volume.

Single-Dose Growth Hormone Vial

Single-Dose Growth Hormone Vial

Your guess is at the spot. This form of growth hormone vial is intended for one-time utility. It will help you in receiving or administering the correct dose without risking product contamination. This vial is discarded after use and you can’t reuse it.

Multi-Dose Growth Hormone Vial

Multi-Dose Growth Hormone Vial- Picture courtesy: LOW -T-MICHIGAN

Certainly, this type of growth hormone vial holds enough product so that you can administer it to multiple patients. Mostly, it is employed in settings where you need numerous doses of growth hormone during the course of time. It is more pocket-friendly for patients.

Multi-dose growth hormone vials include preservatives, which prevent microbial contamination and maintain product efficacy for every use.

5.What are the ingredients and their purpose in the growth hormone vial?

Well, you should know that the growth hormone vial isn’t just composed of growth hormone but various other constituents that allow this formulation to acquire stability and sterility. Hence, for your knowledge, some of the important ingredients and their purpose in growth hormone vial are described in the following section:

Active Constituent

Active Constituent- Picture courtesy: irvinesci

Recombinant growth hormone is the key ingredient in the growth hormone vial and is responsible for the efficacy of formulation. This active component has the same function as growth hormone naturally expressed in the human body.

It treats growth and developmental problems by stimulating cell propagation, regeneration, and metabolism.

Solvent

Solvents- Picture courtesy: Avantor

It is another central part of the growth hormone vial formulation. Typically, solvent serves as a medium for the dissolution of active ingredients and other excipients.

Buffers

Buffer- Picture courtesy: Brittanica

It should come as no surprise that growth hormone preparation is a delicate product that destabilizes upon encountering pH fluctuations. That’s why you’ve buffer in its preparation because they keep the pH within a defined range of 7.5. With this, you can accomplish stability of formulation. Some common buffers include sodium citrate and phosphate buffer.

Preservatives

Preservative- Picture courtesy: USADA

This product is also suspectable to microbial growth and reproduction, so, preservatives, such as phenol, metacresol, and, benzyl alcohol are incorporated during its preparation to deter microbial presence. They are especially added in multi-dose growth hormone vials to safeguard product sterility after recurrent use.

Stabilizers

Stabilizers- Picture courtesy: Sigma Aldrich

Here’s a fact: growth hormone proteins can clump together (aggregate) during storage and transportation, thereby losing their potency when injected. To mitigate this risk, you normally have stabilizers in the growth hormone vial. These excipients, such as polysorbate 20, glycine, sucrose, and, mannitol protect the product from clumping, structural changes, and, denaturing over time.

Tonicity Adjusters

Tonicity Adjusters

This medication also constitutes tonicity adjusters, like sodium chloride, mannitol, and, glycerin to make sure the former corresponds to fluids in the body. Consequently, with this, patients feel minimal pain in the injection area.

6.Can you describe the steps in the production of growth hormone vial?

Production of growth hormone vial is a quite complicated operation involving various biotechnological, pharmaceutical, and engineering steps. All these steps must be performed with strict regulatory compliance to attain quality products.

Now, let’s look at various steps in the production of growth hormone vial:

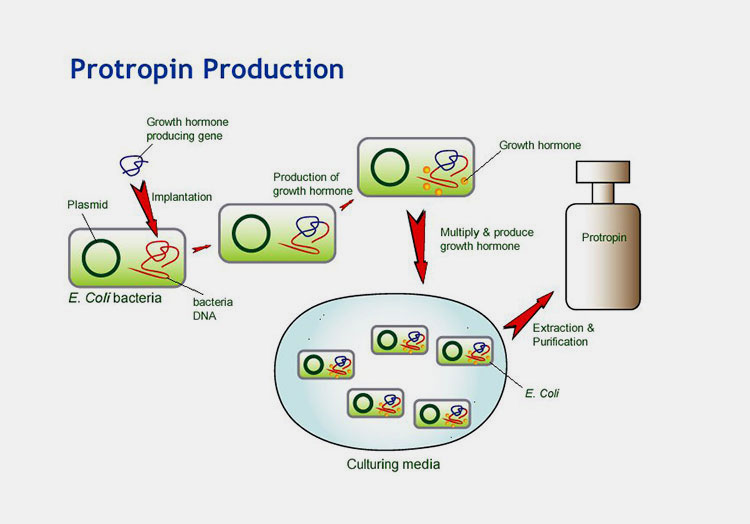

Production of Growth Hormone Vial- Picture Courtesy: EdUHK

Preparation of Recombinant Human Growth Hormone (rHGH)

This stage is composed of several sub-steps- from the creation of recombinant human growth hormone to its isolation and purification. Here is a full overview of all these steps:

| Transformation of Host Cells | In the first step, the gene of human growth hormone is inserted into extra-DNA-like structures in host organisms, such as E-coli and a fungus called Pichia pastoris. This modification of host cells is done using diverse biotechnological techniques involving agents like heat, electric pulse, and chemicals. |

| Fermentation and Cultivation | After the transformation, the next step will be the cultivation and growth of host cells. Optimal growth settings, such as nutrients, oxygen supply, temperature, and pH are supplied to host microbes so that they will produce desired quantities of the rHGH. |

| Extraction | Initially, in this stage, cellular contents are released by disintegrating host cells using diverse physical methods, for example, strong vibrations and increased agitation. Sometimes, you’ll use chemicals called lysis buffers or enzymes to solubilize cell walls and cell membranes. |

| Purification | It is the critical step in the manufacturing of growth hormone vials and is carried out to acquire a highly pure form of rHGH. It occurs in a series of steps to clear out numerous impurities, for instance, microbial proteins, genetic material, endotoxins, and other waste from a solution of rHGH.

To make sure that rHGH is really pure, you can use various chromatography techniques, such as affinity, ion exchange, and size exclusion. |

Formulation of Solvent Materials

Solvent Treatment- Picture courtesy: PODI System

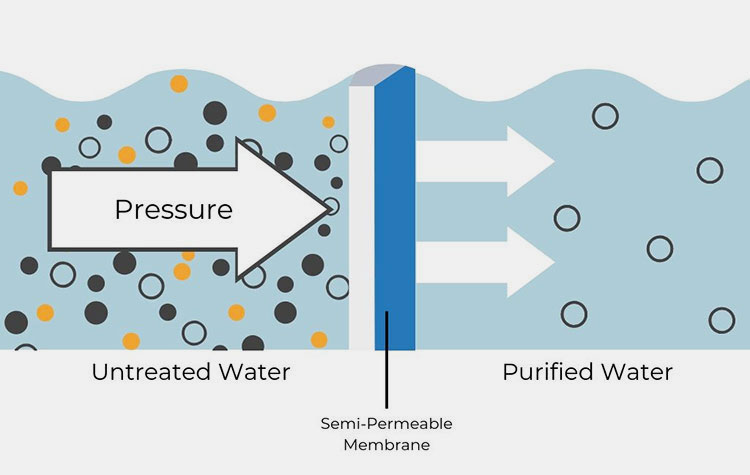

Since the water for injections is the primary solvent used for manufacturing growth hormone vials, you’ve to use different approaches, for example, distillation or reverse osmosis to generate it. These methods involve steam generation and reverse osmosis membrane, respectively.

After that, various buffering agents, tonicity adjusters, cryoprotectants, and preservatives, are added into water for injection to devise a solvent system for suspension of rHGH. Subsequently, you’ll filter this system either with a sterile filtration membrane or with autoclaving to kill any lingering microbes.

rHGH Dissolution and Product Preparation

Dissolution and Product Preparation- Picture courtesy: Bill World

You can consider this step as the heart of the production process. In this process, you carefully solubilize purified rHGH in a solvent system- prepared at the above step. By the end of this step, rHGH is transformed into an injectible formulation. This is achieved by thoroughly and uniformly mixing sterile material into solvents.

At this step, you’ll adjust the pH (usually around 7.5) of the formulated product to match the physiological pH. Finally, you’ll employ sterilization, like sterile filters to filter out any potential microbial debris.

Aseptic Filling

Aseptic Filling- Picture courtesy: Vetter Pharma

Now your packaging process begins. First, your prepared growth hormone solution is dispensed into sterile vials in a process called aseptic filling. You’ve got to carry out this operation in cleanrooms- developed especially to reduce microbial ingress.

At the beginning of this step, vials are moved to the filling area. After that, you’ll relocate the product solution to a vial production line. The filling systems in this unit accurately load a pre-set volume of product into every vial to ensure that the patient will get the correct dose of growth hormone.

Sealing of Vials

Aseptic Vial Sealing- Picture courtesy: Packaging Strategy

Once filling is completed, now it’s time for vial sealing. At first, rubber stoppers are fitted on the necks of vials and then aluminum crimp seals are oriented over stoppers and crimped around vial necks by use of the crimping tool.

Lyophilization

Lyophilization- Picture courtesy: West Pharmaceutical

For manufacturing freeze-dried growth hormone vials, you’ve to lyophilize your partially sealed vials with just stoppers. Initially, you freeze the growth hormone vial at about -40°C or -60°C. Then, a vacuum is created to remove water by the sublimation process. At this step, the water directly changes into vapors, leaving behind a cake-like white powder of growth hormone.

After lyophilization, the vials are fully sealed.

Labeling and Cartoning

Labeling and Cartoning

In the concluding steps of the growth hormone vial, the required labels are applied to the center of the vial. As per FDA and EMA requirements, your labels must include the product name, quantity, dosage type, delivery route, expiry date, storage guidelines, and batch number.

At last, the labeled vials are ready for cartoning. This is done by placing them into sturdy boxes, designed to store one or more vials. You may either protect carton boxes with tamper-evident features, such as tapes or shrink wraps.

7.What equipment is used in the production of growth hormone vial?

The production of growth hormone vial includes a combination of specialized pieces of equipment. Every system in this production has a specific task to yield a safe and potent formulation. Let’s examine each machine one at a time:

Bioreactor or Fermenter

Bioreactor or Fermenter: Picture courtesy: ELSCOLAB

Usually, first, in line, you’ll see large steel stainless tanks called bioreactors or fermenters, used for culturing and prorogating your desired host organism, whether E-Coli or Pichia pastoris. These organisms express large quantities of rHGH in their cells.

These tanks offer a controlled environment to host cells for their growth on a large scale. They can be stirred tanks that feature sensors or other probes for monitoring essential parameters, such as temperature, pH, dissolved air, nutrient volume, and vibration.

Centrifuge Systems

Centrifuge Systems- Picture Courtesy: Labkafe

These devices are typically employed after the fermentation process to harvest and separate cells and microbial cellular fragments from the culture broth. This machine works by generating centrifugal forces or spinning forces to sort the heavier and lighter culture materials.

Moreover, during the purification stage, high-speed centrifuges are also used to fractionate and separate components depending on size and density.

Cell Disruption Equipment

Cell Disruption Equipment- Picture courtesy: ATS Scientific

This unit holds a significant part in the purification of rHGH. The high pressure equipment used to induce high shear force requires to disrupt the cell structure. The unit works with keeping the stable inside constituents which is crucial for cellular extracts and responsible for the isolation of purified rHGH. Generally, this is essential to purify rHGH depending on their molecular size, net charge, binding affinity, and hydrophobicity.

Filtration Systems

Membrane Filtration System- Picture Courtesy: PureTec Separations

At the end of the purification stage, filtration systems, for instance, membrane and depth filters are utilized to clarify isolated rHGH protein solution. Since, the latter might have tiny impurities, like particulate matter or other suspended particles, filtration devices are pivotal in removing these unwanted particles from protein solution.

Water Treatment Plant

AIPAK Engineering Multi-Effect Water Distiller

Since sterile water for injection is the fundamental component of the growth hormone formulation in industry, the water treatment system is very critical in manufacturing this product. In order to purify and sterile water, normally various unit assemblies of water treatment plants, for example, multistage distillation are used to obtain pharmaceutical-grade ultra-pure water.

Vial Filling Production Line

AIPAK ENGINEERING Vial Filling Production Line

Indeed, a vial filling line is a core component of the growth hormone vial production. Because without it, vial packaging is not possible. However, it is worth noting that it has a complicated setup with multiple units, like vial unscrambling, ultrasonic washing, depyrogenation tunnel, filling, and stoppering.

At its starting end, you’ll find a vial unscrambling unit that is like an organizer. It takes vials in random orientation and places them in the right configuration after a fixed interval. Then vial washing system takes them and thoroughly washes, cleans, and rinses them inside out with high-power water spray jets and ultrasonic rays.

Next, you’ll see a large tunnel-like structure, which is a sterilization unit. Here your vials are sterilized using hot air and heat. This unit is vital because, without sterilization, you might have the risk of microbial growth, impacting patient health.

Afterward is the heart of the vial product line- filling and stoppering system. Diverse filling systems are present in this machine to smoothly and precisely dispense growth hormone products into vials. Finally, your filled vials are partially stoppered to perform freeze-drying or fully stoppered and crimped sealed depending upon the nature of the product.

Lyophilizer

AIPAK Vacuum Freeze-Dryer

You can also call it a freeze-dryer. In this machine, you’ll gently evaporate moisture content to obtain a dry powder of growth hormone. Normally, the filled vials are placed on trays of the machine, then frozen at -40-60°C to convert the product into ice. Next heat is applied in a vacuum environment to change solid ice into gaseous vapors (sublimation), leaving behind a white caky product.

CIP/SIP System

AIPAK ENGINEERING Clean Steam Generator

The clean steam generator is present at the final stages of the growth hormone production line. This unit is vital for cleaning-in-place or sterilizing-in-place processes of various machines. It helps in cleaning them without disassembling them. It uses deionized water to produce pure steam with its steam heating system. With pure steam, it disinfects various systems without damaging them in any way.

Labeling Device

AIPAK Labeling Device

Once your vial is fully sealed, labeling devices are then employed to place pre-printed labels on vials. Sometimes, this device also has an integrated printer to print barcode or QR code info for user awareness and lot tracking.

Cartoning Machine

AIPAK Cartoning Machine

Ultimately, at the end of the growth hormone vial production line, you’ve got a cartoning machine. This system aids in securing the growth hormone vials for transportation and retailing by putting and storing them in durable cardboard or paperboard boxes.

8.How to reconstitute the growth hormone vial?

Reconstitution of vials- Picture courtesy: Emergo

As you know, by now growth hormones usually come in dry powder form. So, it must be reconstituted before dispensing. This means that you’ve to add a diluent- usually water or saline solution- to convert into liquid form. Here are some general steps to reconstitute the growth hormone vial:

| Preparation | First, you’ve to clean and sterile the area where you’ll be preparing the growth hormone vial. Next, wash your hands to keep sterility. See the back of the vial to check its expiry date. In this way, you can ensure that the product is still safe to use. Then, wipe the rubber stopper of both the growth hormone vial and diluent with an alcohol swab. |

| Reconstitution | After preparing the station, you’ll use a sterile syringe to withdraw the recommended volume of diluent. Subsequently, puncture the stopper of the growth hormone vial with a syringe needle to slowly load the diluent into the product vial. Always remember to introduce diluent by directing the needle against the side of the vial. This will prevent vigorous shaking of powder. |

| Mixing | Lightly rotate the vial to solubilize the powder in the diluent. Don’t agitate it forcefully, as it might damage hormones. After complete dissolution, ensure that there are no floating bits, chucks, or milkiness in vials. |

9.What water type should be used to reconstitute the growth hormone vial?

Diluent for Reconstitution- Picture Courtesy: Kingsberg Medical

When you’re reconstituting the growth hormone vial, always keep in mind to add sterile water for injection (SWFI) or bacteriostatic water as diluent.

It is preferred as a diluent, as it doesn’t have any kind of microbial impurity, like their cells, spores, proteins, or, endotoxins that might disrupt the therapeutic effect of hormones and cause injection in patients.

Moreover, in contrast to tap or distilled water, there are no chemicals, salts, ions, preservatives, or additives in SWFI. Finally, by adding it, you can be confident that the prepared solution has the correct balance and won't harm your cells in any way.

10.What dose volumes are in the growth hormone vial?

Dose of Growth Hormone Vial- Picture Courtesy: NomadLaB

You may have seen different dose volumes of growth hormone vials at your pharmacies. However, what you might not realize is that these different dosages mainly depend on who produces it, how strong it is, or what it’s used. It is important to understand that dose volumes are expressed in both mg (millimeter) and IU (international units), and,

3 UI= 1 mg rHGH

Now, let’s learn about common dose volumes in growth hormone vial:

| Category | Dose Strength (IU) | Dose Weight (mg) | Use Indication |

| Low Dose Growth Hormone Vial | 4-10 | 1.33-3.33 | Suitable for administration in children or ideal for small-dose use. |

| Moderate Strength Growth Hormone Vial | 12-18 | 4-6 | Usually given in an adult therapy regime. |

| High Strength Growth Hormone Vial | 30-36 | 10-12 | Best for intensive or long-term therapy. |

11.What are other packaging options for this product besides growth hormone vial packaging?

Although vials are the traditional, widely-used, and trusted form of packaging for growth hormone vials, you also have other packaging options besides vials for ease of use and safety.

Prefilled Pens

Prefilled Pens- Picture Courtesy: Kingsberg Medical

These prefilled pens have hidden growth hormone cartridges inside them and feature a dose delivery mechanism. Their packaging may include disposable needles that are attached to the pen. You have to change the dose dial on the pen and administer med by push of a button or plunger. They are portable so you can easily carry them while traveling.

Auto-Injectors

Auto-Injectors- Picture Courtesy: PDD Innovation

It is the latest innovation in the drug delivery system and is favored by patients because it automates the administration process. It is designed in such as way that the needle is hidden both before and after the injection. Medication is dispensed through the hidden needle with a click of a button. This device is best for self-injection and minimizes needle anxiety by concealing it.

Needle-Free Injection Systems

Needle-Free Injection Systems- Picture Courtesy: MedWatch

As the name indicates, this device doesn’t have any needle, instead, it uses a high-pressure fluidized jet to administer growth hormone through a skin layer. Hence, the liquid growth hormone easily penetrates subcutaneous tissues. It is best for individuals who have needle phobia. Moreover, there is no chance of needle injury with a needle-free injection system.

Cartridges

Cartridges- Picture Courtesy: Venom Pharma

It is a tiny growth hormone container made with glass or plastic. It typically comes with a refillable injection pen. You can discard the cartridge once it is empty and switch it to a new one. Each dose costs less if you use a cartridge with a reusable pen.

12.What are some frequent technical errors in growth hormone vial production? How to solve them?

Errors & Solutions- Picture courtesy: Surgical and information

Producing growth hormone vials at a large scale is quite a challenging task, which is further complicated by technical errors. They lower product stability, product quality, and yield. However, you can solve them by reading the subsequent solutions:

Inadequate Freeze Drying of Product

| Problem | Solution |

| It is a very frequent problem that arises when you freeze-dry growth hormone vial. You’ll see that after freeze-drying, there is a small quantity of moisture still left in the products. This has significant consequences, as water content in lyophilized powders is linked with poor stability and decreased shelf-life. | To resolve this problem, you must take the following measures:

Test your lyophilization cycle to confirm the accurate temperature and pressure of each lyophilization stage. Then, use these calculations to set the right settings for every stage. You can prevent the degradation of freeze-dried cake or ice melting with the use of a controlled freezing approach. |

Product Contamination During Aseptic Filling

| Problem | Solution |

| Sometimes, you’ll notice that during vial filling, airborne particles, bacteria, molds, or other particulates might enter the product. This jeopardizes sterility. | Here are some useful tips for you to fix this problem:

Firstly, you must run filling steps in ISO class 5 to maintain a strict cleanliness level. Secondly, train your operators to practice hygienic protocol. Thirdly, you must implement EPA filters and positive air pressure systems in filling areas to ventilate air and remove particular matter. |

Variability in Dose Filing

| Problem | Solution |

| Did you encounter variations in growth hormone volume in vials? Yes, it is a quite troubling problem that could result in a lot of mistakes. | To solve this problem, you can use peristaltic or piston fillers with automated feedback loops to minimize variability in your filling.

You can also integrate weight-checking and volume-detecting sensors to spot fill accuracy in each vial before moving it to the next operational step. Make it your routine to calibrate your filling systems after every shift to ensure complete fill precision. |

Vial Sealing Issues

| Problem | Solution |

| It is one of the major challenges when you’re developing a growth hormone vial. Vial sealing issues could be due to poor-quality stoppers or incorrectly placed caps on vials. | You can skip these problems by using pharma-approved high-quality stoppers. Also, conduct container closure integrity testing (CCIT) on every vial to ensure that they’re properly sealed. Furthermore. Apply the right amount of torque to caps to properly close and secure them on vials. |

Conclusion

To wrap up, growth hormone is a therapeutic approach to treat your growth deficiencies, improve your metabolism, and maintain your body mass. Generally, you can get this treatment in clear glass vials. Hopefully, by reading this FAQ guide, you’ll be able to understand its benefits, ingredients, production steps, manufacturing equipment, and packaging styles. If you belong to the pharma industry and want to upgrade or renovate your equipment related to growth hormone vial production, then you’re welcome to contact us, AIPAK Engineering by filling in the form below. We are ready to guide you on your selection journey.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours