HPV Vaccine Production The Complete FAQ Guide In 2025

Have you ever learned about the production and packaging process of HPV vaccines? The preparation of HPV vaccines is a complex and tedious process. It can meet specific vaccination effects. In order to pursue high-quality, efficient and innovative HPV vaccine production processes and solutions, our researchers are working hard and making efforts.

In order to improve the production of innovative HPV vaccines, this post focuses on the production process of vaccines and the challenges that will be encountered later. Hope it can solve all your problems about HPV vaccine production. Check it out now!

1.What Is HPV Vaccine And How It Works?

What Is HPV Vaccine And How It Works-sourced: bbc

HPV vaccine is a vaccine specifically used to prevent cervical cancer. In addition to cervical cancer, it can also prevent oral cancer, pharyngeal cancer, head and neck cancer, etc. caused by HPV virus. It is now widely used in women, and with the development of the vaccine, it is gradually becoming popular in the male group.

2.Who Is The HPV Vaccine For And When Should It Be Given?

Who Is The HPV Vaccine For And When Should It Be Given-sourced: hawaiipacifichealth

HPV vaccine is a type of vaccine of cervical cancer prevention for all women and men. It is specifically for women or men between the ages of 11 and 12, 15 to 26, and 27 to 45. Different types of vaccines are used among women of different ages. Generally speaking, experts suggest that 11 to 12 years old is the best time to start HPV vaccination.

A total of two injections are required. In the later period, the age group for HPV vaccination is 15 to 26 years old. A total of three injections are required. The last one is suitable for women between the ages of 27 and 45.

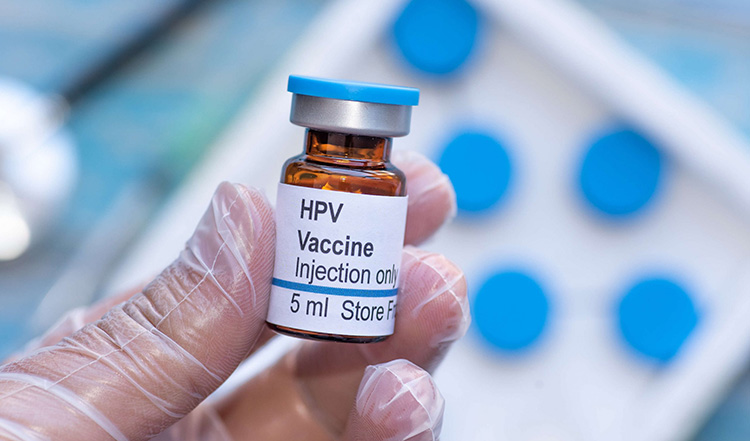

3.What Is The HPV Vaccine Production?

What Is The HPV Vaccine Production-sourced: ritaibioreactor

The production of HPV vaccine refers to the process of sterilizing, producing and packaging HPV vaccine through a series of equipment and technical means in a moderate environment. The early stage mainly includes the yeast cell culture and sterilization of HPV virus, and the later production and packaging.

4.What Is The HPV Vaccine Production Process?

HPV vaccine production involves many complicated stages. Each stage needs to be strictly controlled to ensure the integrity, stability and high quality of the vaccine. It mainly includes the following steps:

Step 1: Virus or bacteria preparation

Virus or bacteria preparation-sourced: technologynetworks

Firstly, you can perform virus or bacteria preparation. You need strain library, cell culture box, biological safety cabinet, liquid nitrogen tank, etc. These equipment have the function of screening, amplifying and preserving various highly immune HPV virus original microorganisms. The whole process includes the recovery of HPV strains, subculture, virulence and purity detection, and the establishment of working seeds later.

Step 2: Large-scale bacterial culture

Large-scale bacterial culture-sourced: technologynetworks

If you want to complete the large-scale bacterial culture, you may make good use of fermentation tanks and centrifuges. It can help you industrially produce HPV pathogens. The fermentation tank is mainly made of stainless steel, and the centrifuge is to harvest more bacterial protozoa. During the virus culture process, you should pay attention to the various operations and feedbacks of the cell factory and bioreactor, control and changes of parameters such as temperature, pH value, and nutrient content.

Step 3: Bacterial inactivation treatment

Bacterial inactivation treatment-sourced: baamboozle

Bacterial inactivation treatment refers to inactivate pathogens, retain the originality of the HPV virus and ensure its safety. To fulfill that purpose, you can apply equipment like inactivation tank with stirring and temperature control and an inactivator addition device. Its main process includes inactivating pathogens in the inactivation tank and then verifying the inactivation effect.

Step 4: Emulsification mixing

ALLPACK emulsification mixing machine

The emulsification mixing mainly refers to use a high-pressure homogenizer with an emulsification tank for high-speed shearing, and an adjuvant preparation tank that can mix mineral oil and emulsifiers. It can mix the inactivated HPV virus with the oil adjuvant to form a stable emulsion. Among them, you need to control the key parameters, including emulsification temperature, speed, particle size uniformity detection, etc.

Step 5: Vaccine packaging and sub-packaging

Vaccine packaging and sub-packaging system-sourced: springernature

The vaccine packaging and sub-packaging mainly includes vaccine bottles automatic packaging, capping, labeling, and cartoning. You can pack inactivated and prepared HPV vaccine into sterile containers, such as glass bottles and plastic bottles. Throughout the process, you need to achieve a high level of cleanliness and control the sterile environment, temperature and humidity requirements of the environment accurately.

Step 6: Quality control

| Raw material testing

Raw material testing-sourced: previnex |

After been manufactured and packaged, you need to make the quality control. Firstly, you need to test the purity of the inactivated strains, the composition of the adjuvants, and the sterility of the culture. Monitor the production process and, if necessary, test the intermediates. The test standards include the inactivation effect, the concentration of the antigen, the emulsification, etc. |

| Finished product testing

Finished product testing-sourced: njlabs |

After performing the raw materials testing, you can test the effectiveness, safety and stability of the vaccine virus through PCR instruments or ELISA detection systems. Safety tests include sterility tests and abnormal toxicity tests. Efficacy tests include animal challenge tests and antibody titer determination. Stability tests include accelerated aging tests and shelf life verification. |

Step 7: Waste processing

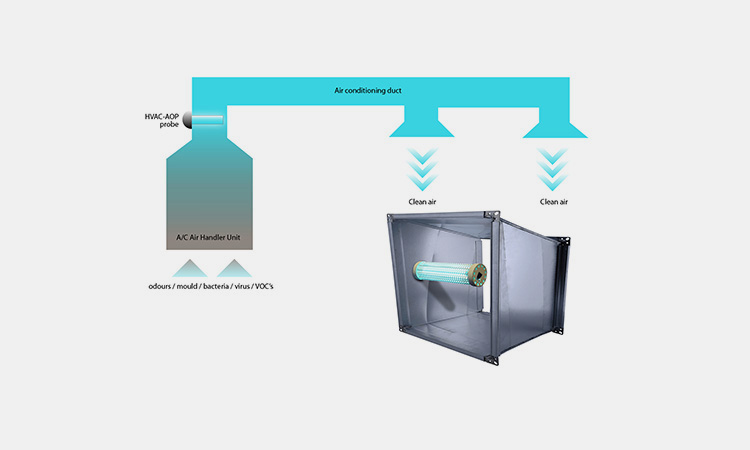

| Air purification

Air purification-sourced: marinevac |

The waste air needs to be processed before emission. Air purification can control the clean room level, such as fermentation area, filling area, etc. |

| Sterilization

Sterilization-sourced: yasuico |

Sterilization includes wet heat sterilizers for bottles and equipment sterilizing, culture media, instruments, dry heat sterilization tunnels, etc. |

| Waste treatment

Waste treatment-sourced: metchem |

Waste treatment include fire extinguishing wastewater treatment, high temperature sterilization or incineration of biological waste, etc. |

Step 8: Storage

| Cold chain storage

Cold chain storage-sourced: who |

After the finished product is made and packaged, the vaccine needs to be refrigerated or frozen in an environment of 2~8℃. The production area must be strictly divided into clean area, live virus area, and inactivated area to prevent cross contamination of vaccines with other materials during the production process. |

5.What Are The Equipment For HPV Vaccine Production?

There are many equipments for HPV vaccine production, mainly including:

Purified water equipment

AIPAK Engineering purified water equipment

Purified water equipment is specially used for making professional cleaning equipment or for preparing mixed solutions. This professional water treatment system can remove various precipitations, impurities, minerals, chemicals and toxic substances in natural water through a series of water purification processes.

Fermentation tank

Fermentation tank-sourced: vida

Fermentation tank, also known as FV. It can be used for bacterial and microbial fermentation in both the pharmaceutical and food industries. This tank can provide a relatively good development environment for microorganisms, and can also provide a good container for the initial virus culture of your vaccine. Fermentation tank has a variety of materials and types for you to choose from.

Centrifuge

Centrifuge-sourced: labcentrifuges

Centrifuge is an experimental biological device. It can provide you with three angle rotors, high-speed stability and safe centrifugation applications. Equipped with a unique rotor, it can horizontally separate different mixed liquids or blood. Designed with a unique imbalance detection system, the device can automatically shut down when the test tube in the device breaks.

Inactivation system

Inactivation system-sourced: pickheaters

The Inactivation system is designed for recycling biological waste. The biological extinguishing waste in the treatment tank is directly thermally inactivated by steam ejectors. After this step, the biological waste can be sent to the self-retention pipe and then circulated to the waste storage tank. This whole process is fast, efficient and has very good time and temperature control.

Waste water sterilizer for inactivation of liquids

Waste water sterilizer for inactivation of liquids-sourced: crystalquest

During the production process of vaccines, wastewater will be generated, whether it is equipment, filling containers, or solution preparation, especially in the early experiments and preparation process. Wastewater generated during the production process cannot be discharged through domestic water pipes and needs to be treated by waste water sterilizer for inactivation of liquids. The treatment equipment can inactivate bacteria or viruses in wastewater before treatment and discharge.

Vacuum emulsifying mixer

ALLPACK vacuum emulsifying mixer

Vacuum emulsifying mixer is a kind of emulsifying and stirring equipment specially used for liquid and viscous bodies. When some vaccines need to add emulsifying adjuvants, this equipment is needed. It is not only used in the pharmaceutical industry, but also widely used in various food, chemical, cosmetics industries, etc. In the vacuum tank, it can provide you with various bacterial adjuvants or output high-stability and high-quality emulsions.

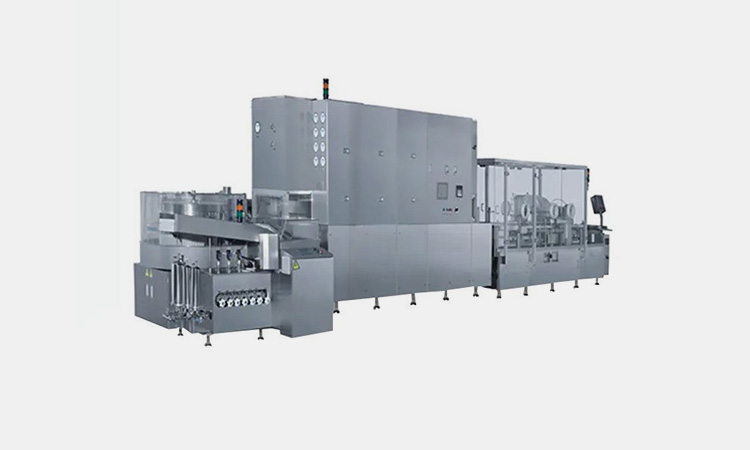

HPV vaccine ampoule filling line

AIPAK Engineering HPV vaccine ampoule filling line

The HPV vaccine ampoule filling line can fill inactivated and tested HPV vaccine cans into different containers. It will provide you with a sterile production environment and can provide sterilization and cleaning systems. It provides an excellent environment and high-quality output rate for your vaccine production. This equipment can easily handle various materials with high efficiency and meet various safety standards.

Pharmaceutical autoclave

AIPAK Engineering pharmaceutical autoclave

Pharmaceutical autoclave is a device specially used for vaccine sterilization. It is widely used in pharmaceutical, healthcare, biochemical and other industries. It provides high-efficiency sterilization for your vaccine by forming high temperature, high pressure, etc. in the tank. Its main working principle is to destroy the spores and protein structure in bacteria, thereby providing high-quality bacterial sterilization, etc.

Ultra-high temperature sterilization

Ultra-high temperature sterilization-sourced: fruitprocessingmachine

Ultra-high temperature sterilization is abbreviated as UHT sterilization. It mainly uses ultra-high temperature to sterilize high-viscosity materials and filling containers. This high temperature can be heated to 137°C-140°C. Through high-temperature disinfection and sterilization, the vaccine can be stored for a longer time and the quality can be better preserved, and the safety and stability of microorganisms can be ensured.

PCR instrument

PCR instrument-sourced: igenels

PCR instrument is a laboratory professional equipment for studying the structure of biological molecules. It can amplify the molecular structure in HPV into small fragments. It is very important for studying molecular structure and components. PCR instrument is an indispensable part of the laboratory. It is very important for the study of HPV virus and gene sequence. It is crucial to promote the development of equipment technology.

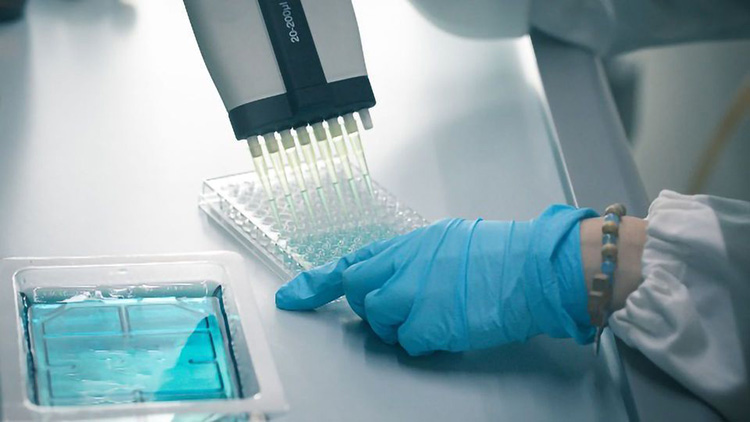

ELISA detection system

ELISA detection system-sourced: technologynetworks

ELISA detection system is a common laboratory equipment. It can be used to detect certain antibodies, antigens, proteins and hormones in pathogens or bacteria. In the process of HPV vaccine research and production, it can detect and test pathogens and antibodies in fire-killing bacteria, which greatly promotes the research and production of HPV vaccines.

6.Is It Important To Optimize The HPV Vaccine Quality And Scalability?

HPV Vaccine Quality And Scalability-sourced: nowserving

The quality optimization and scalability of HPV vaccines are very important. In the field of vaccine production, in addition to improving the quality of the vaccine itself, it is also very important to protect everyone's life, improve their health, expand the popularity of vaccines, enable different groups of people to develop sustainably, enhance the resilience of public health, and improve people's living standards and medical standards.

7.What Are The Challenges For HPV Vaccine Production?

In the future, the challenges of cervical cancer vaccines mainly lie in two aspects. These include:

Cold chain storage

Cold chain storage-sourced: viastore

After the HPV vaccine is produced and packaged, it still needs to be well stored, transported and tracked. Vaccines are sensitive, and their activity is sensitive to external environmental temperature, humidity and sunlight, so cold chain storage is a big challenge.

8.What Are The Innovative Approaches For HPV Vaccine Production?

The innovative approaches for HPV vaccine production is:

Single-dose vaccines are gradually eliminated

Single-dose vaccines are gradually eliminated-sourced: sog

In the process of HPV vaccine production exploration, single-dose vaccines are gradually eliminated, replaced by two to three injections. This technological development and scientific progress not only improves the universality of cervical cancer vaccination, but also improves the professionalism, high quality and stability of vaccines in production, later packaging and later application in actual processes.

9.What Are The Melt-Processing Technology For HPV Vaccine Production?

Melt-Processing Technology For HPV Vaccine Production-sourced: zeesandx

Melt-processing technology for HPV vaccine production is a type of vaccine production process. It provides excellent scalability for cervical cancer vaccine production and greatly improves vaccine production efficiency. This method mainly combines heat and pressure to seamlessly encapsulate virus sample particles in organisms such as PLGA. This organism can continuously ensure the stability and release of antigens.

This method does not require any solvents or cold chain logistics. This is very important for global vaccine vaccination and subsequent quality control. Because this production technology and method can ensure that the vaccine does not contain any solvents, it also increases the sensitivity of viral proteins to temperature. It not only ensures the integrity of virus encapsulation and the stability of later use, but also solves the pressure of later pharmaceutical and environmental aspects.

10.What Are The Benefits Of Melt-Processing Technology For HPV Vaccine Production?

This technology solves the cold chain challenge in the traditional cervical cancer vaccine production process, and it can bring the following benefits:

Thermal stability

Thermal stability-sourced: ddw-online

After adopting this production method, the cervical cancer vaccine can provide the virus with stronger thermal stability, ensuring that the pathogenic antibodies of the virus can maintain integrity and high quality even during high-temperature processing.

No solvent required

No solvent required-sourced: bakerinstitute

Eliminates the dependence on solvents in the production process of cervical cancer vaccine. This not only reduces environmental pressure, but also reduces pharmaceutical challenges.

Scalability

The use of such technology can greatly improve the efficiency and large capacity of cervical cancer vaccine production. This also greatly expands the probability and efficiency of vaccination for women.

Cold chain dependence

Cold chain dependence-sourced: unicef

The invention of this technology completely helps cervical cancer vaccine get rid of cold chain dependence. This not only reduces its demand for cold chain logistics, but also simplifies the difficulty of this vaccine in the later transportation and storage process, saves costs, and simplifies the distribution process.

Multiple dosage forms

Multiple dosage forms-sourced: samitivej

This method greatly improves the stability of the vaccine and expands the popularity of the vaccine.

11.What Are The Future Prospects For HPV Vaccine Production?

Future Prospects For HPV Vaccine Production-sourced: hollingscancercenter

In the future, the development of cervical cancer vaccines and the subsequent production and packaging process will also face more challenges. However, the biggest prospect is to minimize the obstacles of logistics to ensure that high-quality vaccines can cover users all over the world and improve global health and sanitation.

While reducing costs as much as possible, it can also simplify the production process of subsequent production, packaging, transportation and vaccination. This not only improves the flexibility and adaptability of the vaccine, but also can deal with this infectious disease through different solutions, so that this infectious disease can be completely defeated by humans.

Conclusion:

The development of HPV vaccine production can be greatly improved in the future. Through continuous research and progress by humans, the complete disappearance of this virus will soon become possible. Global sanitation and health conditions will be greatly improved. Through this complete FAQ guide of HPV vaccine production, if there are more you want to know, please contact AIPAK Engineering now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours