Liquid Curcumin Manufacturing: The Complete FAQ Guide In 2025

Ever thought about how yellow spice- turmeric- has changed into a health-boosting liquid extract- curcumin- that has become a major staple fixture of nutraceutical markets around the world?

Well, the answer to your curiosity lies in liquid curcumin manufacturing. The curcumin supplement you see on aisles is due to advanced and innovative techniques included in liquid curcumin manufacturing.

Are you in the business of supplement manufacturing, R&D technologies, or simply interested in knowing the intricacies of botanical extract, you probably have various queries about liquid curcumin manufacturing. So, in this FAQ-styled guide, we’ll answer your every question clearly and practically. Let’s explore the approach behind making this golden elixir!

1.What is liquid curcumin? How does it differ from powdered curcumin?

Liquid Curcumina

Although turmeric has long been celebrated for its powerful health benefits, however, liquid curcumin- a compound present in turmeric- has taken fitness enthusiasts worldwide by storm. Liquid curcumin is a well-utilized form of raw curcumin.

It is prepared by different novel approaches that boost its solubility in the liquid phase and bodily uptake. Liquid curcumin is present in the market in shot, drops syrup, and tincture forms.

On the other hand, powdered curcumin is derived from the extraction of turmeric roots and is taken as pills or powder mixed with food and beverages. It has low body assimilation because of its hydrophobic nature.

Liquid curcumin is vastly different from powdered curcumin because of its fast therapeutic action, improved bioavailability, easy dosing, higher convenience, and taste-making potential.

2.What is liquid curcumin manufacturing?

Liquid Curcumin Manufacturing – Picture Courtesy: CODEAGE

Liquid curcumin manufacturing is a series of operational steps in which the liquid curcumin is developed by extracting powdered curcumin from the turmeric roots and converting it into liquid for improved bioavailability. In this manner, its absorption rate from the digestive tract is increased.

You can think of this industrial process as an operation in which liquid formulation containing curcumin is formed using diverse industrial steps, for example, extraction, purification, blending, quality assessment, and packaging. Also, specialized equipment and high-quality raw materials are utilized in liquid curcumin manufacturing to acquire safe, potent, and, high-quality liquid curcumin.

3.Why liquid curcumin manufacturing has gained popularity in nutraceutical sectors?

As curcumin supplements are all the rage in the current decade, so you have surely heard about expansion in nutraceutical sectors to include liquid curcumin manufacturing. Since demand for liquid curcumin is at an all-time high, having this type of manufacturing in nutraceutical setups is bound to bring a huge array of benefits.

Let’s have an insight into diverse advantages of liquid curcumin manufacturing:

High Absorbed Quantity

High Absorbed Quantity – Picture courtesy: Revolution Fermentation

Surely, it is one of the biggest advantages of liquid curcumin manufacturing. Curcumin in powdered form is difficult to absorb by the body. However, its bioavailability climbs sharply when it is in liquid form. This means faster action of curcumin in the body, offering more noticeable health benefits even with tiny doses.

A Powerpack Bundle of Convenience

Powerpack Bundle of Convenience- Picture courtesy: BIO TOP LEVEL

Liquid supplements are favored by many consumers because of their convenience. With liquid curcumin manufacturing, nutraceutical brands create liquid preparations that are easily stored in bags and travel packs and consumed at any time of day. Moreover, you can consume it by just taking a spoonful from a bottle without worrying about preparing doses, which is often the case with powders.

Vast Product Uses

Vast Product Uses – Picture courtesy: AMY HILTON

Liquid curcumin manufacturing has acquired traction in the nutraceutical setups because its product is the manufacturer's dream. Did you think that liquid curcumin is only used in capsules? Certainly not, you can incorporate it into functional drinks, fitness shots, tinctures, smoothies, and soups. This versatility has led to the development of innovative formulations.

Easy to Shallow Treatment Format

Easy to Shallow Treatment Format

Let’s be real, several individuals have a fear of taking pills and they’re unable to swallow them. Liquid curcumin manufacturing develops products that are preferred by many patients, especially children and the elderly. They favor liquid quick sips over giant pills. Moreover, liquid curcumin also helps in overcoming pill fatigue.

Longer Product Expiration Period

Longer Product Expiration Period- Picture courtesy: insights.tessmed

Liquid curcumin manufacturing offers wellness enthusiasts a powerful remedy that comes with an extended shelf life. Why is that? Nutraceutical brands include various stabilizers and preservatives in their formulation while packaging the liquid curcumin is airtight packaging. In this way, they protect their products and keep them safe from physical, chemical, and biological impurities.

4.What are the principal ingredients in liquid curcumin manufacturing?

Before reading about the steps involved in liquid curcumin manufacturing, first, you must learn about the principal ingredients used in it. These key players not only make this golden preparation but also offer it potency and stability. Here is a detailed description of the ingredients utilized in the preparation of liquid curcumin.

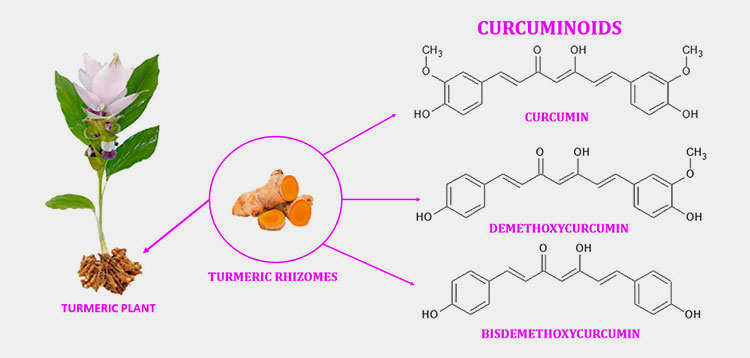

Curcumin Extract

Curcumin Extract- Picture courtesy: Everyday Health

You can consider it a star of liquid curcumin preparation. It is mainly obtained from the roots of the turmeric plant. It has concentrated quantities of curcuminoids. It is normally acquired in powdered form and then dissolved in solvents. Curcumin is best known for its anti-inflammatory and antioxidant properties.

Solvent

Solvent- Picture courtesy: Botaniq

It is another major component in liquid curcumin preparation, as you can’t obtain a liquid preparation without the use of solvents. They provide a medium to solubilize and suspend curcumin. Mostly purified water is used as a solvent but MCT oil can be employed for dissolving oil-based or liposomal curcumin. Glycerin is utilized in some instances for thickening formulation.

Surfactants

Surfactant – Picture courtesy: Actera Ingredients

They are like detergents with both poplar and nonpolar constituents. These parts aid in the mixing of formulation ingredients in both the water and oil phases. In this way, you can have a stable and homogenous emulsion in which curcumin doesn’t settle down. They may include polysorbate 80, lecithin, and PEG-based surfactants.

Absorption Boosters

Absorption Boosters- Picture courtesy: GoToChef

How does liquid curcumin have better absorption? It is because of absorption booster compounds included during its preparation. They help in the better absorption of curcumin from the gastrointestinal system so that more of the treatment reaches its target area to deliver its effect. Absorption boosters are piperine or nanoemulsifying agents.

Preservatives

Preservatives

They aid in extending the usage period of liquid curcumin and ascertain that it will retain its safety and potency till its expiration rate. Their examples are citric acid, potassium sorbate, and, xanthan gum (natural).

Flavor Enhancers

Flavor Enhancers

They are added to the formulation to improve its flavor. Liquid curcumin is taken orally, so it should have a better flavor profile. You can use both natural and artificial flavors or sweeteners like stevia.

Food Dyes

Food dye- Picture courtesy: Florida crystal

They are 100% food-safe and are incorporated sometimes during liquid curcumin manufacturing, as the natural yellow color of turmeric is usually enough to enhance supplement appeal.

5.What are the primary working stages in liquid curcumin manufacturing?

Working Stages In Liquid Curcumin Manufacturing – Picture Courtesy: QUNOL

Liquid curcumin manufacturing doesn’t consist of a single step but multiple stages occur in this production to produce excellent-quality liquid curcumin. It includes several different testing studies, designing, extraction, and packaging.

And for your information, we’re describing all these primary working stages one by one in the following sectors.

Selection of Raw Material

Selection of Raw Material- Picture courtesy: MDPI

As you already know curcumin is derived from turmeric roots that are harvested largely from India and China. After that, these harvested plants are washed, cut, and dried either using direct sunlight or with dryer machines and then pulverized into finely ground powder that is used for the extraction of curcumin.

Extraction

Extraction- Picture courtesy: Botanic health

In order to isolate curcumin from the turmeric roots, various methods are used in which manufacturers employ solvents, such as ethanol, carbon dioxide, and ultrasonic waves. These approaches mainly work by increasing the solubility of curcuminoids in solvents.

This step produces a concentrated form of curcumin, normally containing about 90-95% of curcuminoids.

Solvent Extraction

| First and foremost is the solvent extraction method. It is one of the oldest methods of curcumin extraction and still is considered as standard for its isolation. Solvent extraction is widely used by commercial plants because of its lower cost. After curcuminoids dissolution, these solvents are vaporized, generating less volatile curcuminoids in a more concentrated form. |

Solvent Extraction- Picture courtesy: Kumar Metal |

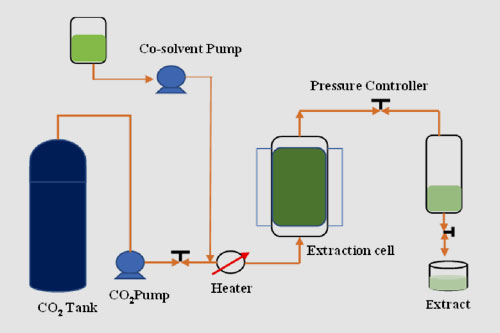

Supercritical CO₂ (SC-CO₂) Extraction

| You’ve guessed it right, in this procedure, carbon dioxide is used for extracting curcumin from turmeric. This method is named as such because of the supercritical state of carbon dioxide, which is achieved using high temperature and pressure critical points (31.1 °C and 7.38 MPa or 73.8 bar).

In this state, it shows both liquid and gas properties. So, you’ll pass this SC-CO₂ through turmeric powder and this gas behaves as a solvent and dissolves curcuminoids. After that, SC-CO₂ and the extracted curcumin mixture are transferred to a separator device, where you lower the pressure. Consequently, SC-CO₂ transitions back to a gaseous state, which causes the precipitation of curcumin. |

Supercritical CO₂ (SC-CO₂) Extraction- Picture courtesy: MDPI |

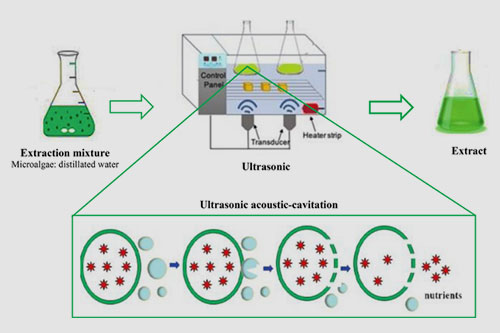

Ultrasound-Assisted Extraction (UAE)

| It's like an assistant to the solvent extraction method. Ultrasonic waves are utilized to increase the solubility of curcuminoid compounds in solvent. The purpose of sound waves is to create cavitation bubbles in the solvents, which break the cell walls of turmeric and increase the discharge and solubility of curcumin in solvents.

It is a more quick and cost-effective method owing to its less use of solvent. |

Ultrasound-Assisted Extraction (UAE) |

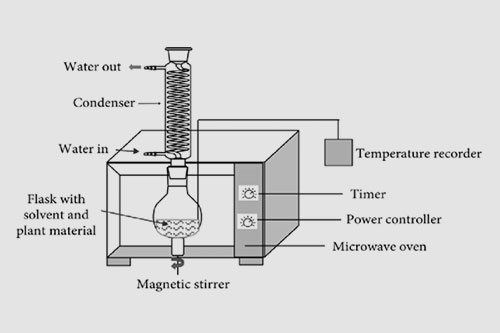

Microwave-Assisted Extraction (MAE)

| You are spot on. This method is similar to the UAE method but instead of using sound waves, it utilizes microwaves. The energy of these waves is essential in heating the solvent and turmeric powder mixture, which aids in the dissolution of curcuminoids. It is a quick and sustainable method and is suitable for heat-sensitive compounds. |

Microwave-Assisted Extraction (MAE) |

Emulsification of Curcumin

Emulsification of Curcumin

As you are aware curcumin powders are very difficult for the body to absorb, therefore, liquid curcumin manufacturing uses different innovative techniques to boost the absorption rate of curcumin. By these procedures, you can transform powdered curcumin into a liquid state that is easily used by the body.

Now, the liquid curcumin is dissolved or suspended in various solvents, like water, oil, or glycerin to create a stable product. Sometimes, emulsifiers are also incorporated at this stage to improve the dispersion of liquid curcumin. Then, the resulting blend of liquid curcumin is uniformly mixed and homogenized. In this way, you can ensure that liquid curcumin doesn’t precipitate at the bottom after its packaging.

Quality Check and Packaging

Quality Check and Packaging

Once all the main formulation steps are completely done, now you can assess the quality of the product using various testing approaches. If the formulation successfully passes through quality control, then it’s time for packaging.

The liquid curcumin formulation is transferred to filling systems, where its specified volume is accurately dispensed into bottles or other packaging formats. After filling, the bottles are capped, sealed, labeled, and boxed. Finally, the formulation is ready for distribution.

6.What kind of equipment is present in liquid curcumin manufacturing?

Liquid curcumin manufacturing constitutes a diverse set of machines. Each of these systems is responsible for a specific task in the production of liquid curcumin. So, let’s learn about each piece of equipment to get a basic understanding of its working:

Dryer

AIPAK Vacuum Freeze Dry Machine Lyophilizer Machine

Dryer is typically the first machine in liquid curcumin manufacturing. It is used for vaporizing the watery content from the turmeric root pieces. Mostly, vacuum dryer, freeze dryer or vacuum lyophilizer are used for bulk-volume operations. High heat is used to evaporate the water, resulting in fully dried turmeric pieces.

Grinding Mill

AIPAK Grinding Mill

It is also known by the name of pulverizer and is required when you want to crush dried turmeric roots into fine powders. It basically works by using diverse kinds of impact devices, such as steel balls, hammers, rollers, pins, discs, steel rods, or compressed air. Raw materials are ground into smaller pieces through impact and attrition.

Sifting Machine

AIPAK Sifting Machine

Sifting machine is needed when want to achieve homogeneity in the particle sizes of turmeric powders. It uses diverse kinds of sifting screens to filter out particles with specific sizes. It outputs powders with ideal dimensions, subsequently helping in smoother down-the-line processes.

Extraction Devices

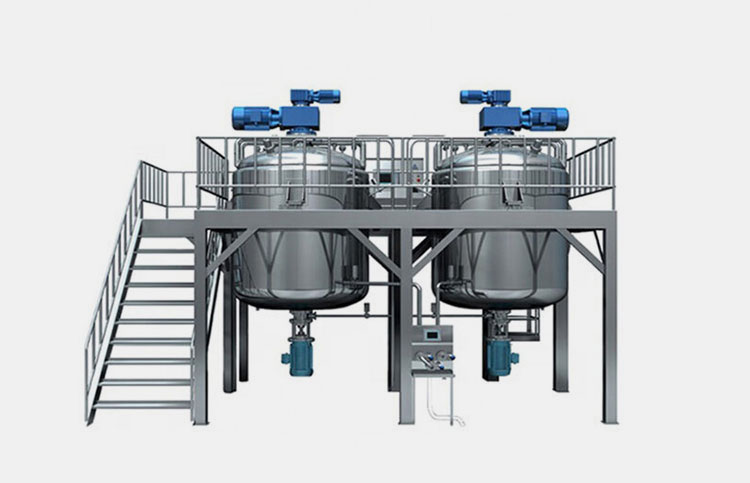

AIPAK ENGINEERING Multi functional Extraction Devices

Indeed, it is the heart of the entire liquid curcumin manufacturing line. Depending upon your product needs and budget requirements, you can either utilize extraction machines such as: a solvent extraction tank, supercritical CO₂ extractor, or, ultrasonic-assisted extractor. Extraction devices are generally large steel tanks and high-pressure vessels that may feature stirring devices and heating and cooling jackets to effectively extract curcumin from turmeric powders.

Purifying System

Purifying System- Picture courtesy: Hunan Micheal

For the purification of extracted curcumin, this device is pivotal in liquid curcumin manufacturing. The purpose of this unit is to remove undesired solid fragments, undissolved plant substances, debris, or, other contaminants from crude extract. You can use frame filters, centrifuge filters, and cartridges to acquire highly pure curcumin extract.

Vacuum Emulsifier Mixer

AIPAK Vacuum Emulsifying Mixer

Needless to say, that liquid curcumin formulation is composed of diverse types of ingredients in addition to liquid curcumin. Subsequently, to mix and blend them all, you certainly require a system that finely dissolves every ingredient in the solvent phase. For this, you might use a vacuum emulsifying mixing device.

It has a fairly simple mechanism of working in which rotary impellers are used under vacuum conditions to generate shear forces that facilitate consistent mixing of ingredients in the liquid phase.

Liquid Curcumin Filling Line

AIPAK ENGINEERING Liquid Curcumin Filling Line

The liquid curcumin filling production line having different units, for instance, an unscrambling unit, bottle washing machine, drying tunnel, filling system, and capping machine. In this production line, bottle unscrambler orient randomly ordered bottles and bottle washing machine employs fast spraying systems and ultrasonic waves to dislodge impurities from bottles.

Then, in the sterilization unit, high temperatures are used for sterile and dry bottles. Afterward, filling systems are utilized for pouring liquid supplements into bottles, and then capping systems seal them securely.

7.What solubilization technologies are employed in liquid curcumin manufacturing?

Solubilization method- Picture courtesy: Crafter choice

Curcumin is naturally hydrophobic meaning it doesn’t dissolve in water under normal conditions. Hence, manufacturers employ different innovative solubilization techniques to improve their solubility and stability in water.

| Micelle Technology

|

As you have already read about surfactants. They’re used in liquid curcumin manufacturing to improve its absorption. They form tiny structures made of two ends- the head that is hydrophilic (water-loving) and the hydrophobic tail (water-hating). When they are placed in water, they form tiny ball molecules with curcumin at their center. The tail ends go inward, interacting with curcumin, while the head ends are in contact with water. |

| Liposomal Encapsulation

|

In this technology, liposomes are used for encasing or encapsulating curcumin. Liposomes are hollow spheres formed by fat-like molecules called phospholipids. Yes, they are the same type of molecules, making up the outer boundaries or membrane of our cells. They are like microscopic delivery vehicles that deliver curcumin to target tissues. |

| Nano-emulsion Technology

|

It is a solubilization technique in which you’ll initially dissolve curcumin in a tiny quantity of oil. Then this oily phase is reduced into nano-sized minute droplets. Following that water and surfactants are added to stabilize the oily phase. By the end, you’ll notice the formation of the milky or clear solution. In this solution, curcumin is encased in nano-sized droplets that are homogeneously mixed with water. |

| Cyclodextrin Complexation

|

To put it in simple words, cyclodextrins are structures that have a ring or donut shape and are created from starch (sugar). Their core is water-hating, so it traps curcumin inside it, while its outer surface is water-loving, thus it attracts water. Curcumin is accommodated inside the cyclodextrin core, consequently, effectively increasing its solubility in water and stability in liquid formulation. |

8.What packaging is included in liquid curcumin manufacturing?

Many people believe that packaging in liquid curcumin manufacturing is only used to make products look pretty. But what they don’t know it is also employed for product preservation, protection, and stability.

Here is a complete list of packaging formats that keep liquid curcumin safe and potent:

Glass and Plastic Bottles

Glass and Plastic Bottles

If you've visited supplement stores, you've likely seen ample supplies of liquid curcumin in glass or plastic. This sheer number of bottles is because numerous manufacturers prefer to pack their products in bottles. For forming plastic bottles, mostly FDA-approved plastic (HDPE or PET) is used. These bottles are less expensive and have shatter resistance.

On the other hand, glass bottles are used for premium and high-end packaging of liquid curcumin. You’ll see liquid curcumin in amber-colored glass bottles. This is because these bottles provide the highest form of protection against light and oxygen. Furthermore, glass doesn’t react with curcumin, thereby, preserving its potency.

Dropper Bottles

Dropper Bottles

As the name indicates, dropper bottles are sealed with dropper caps. They are the customers' dosing dreams. With droppers, customers not only have convenience in usage but also precision in dosing. You can find these bottles in both glass and PET plastic material.

Liquid Sachet Packs

Liquid Sachet Packs

In the present on-the-go era, liquid sachet packs are quite trendy. They’re well-liked by people who are always traveling because sachets are portable, lightweight, and have a single dose of liquid curcumin. They’ve smaller dimensions and are manufactured from multi-layer laminated foil.

9.What are the challenges associated with liquid curcumin manufacturing? How to solve them?

Liquid curcumin manufacturing is not as simple as one might think. As, it is comprised of different innovative approaches and specialized machines, which necessitate careful handling and management during operation.

However, issues still emerge during operation, despite your best efforts to prevent them. Are you interested in exploring ways to overcome these challenges? Then read the below-mentioned common challenges of liquid curcumin manufacturing and their remedies.

Issues in Curcumin Solubility

Curcumin Solubility

It is one of the biggest challenges in liquid curcumin manufacturing. Curcumin has a water-hating nature so, it has poor water solubility. This makes it difficult to form a stable and drinkable liquid formulation.

Solution

To solve this issue, you’re required to employ innovative procedures discussed in the above section. Some of these methods include micelle formation, nano-emulsions, and liposomal encapsulation. These methods improve curcumin dispersion in water by trapping it inside various molecules.

Poor Bioavailability of Curcumin

Poor Bioavailability

This challenge will arise even if you mix curcumin into the water and form a stable formulation. It is a well-known fact that curcumin has poor bioavailability and the body barely absorbs it. Because most of its fraction is degraded by the stomach before it exhibits its therapeutic effect.

Solution

Fortunately, there are some well-tested approaches to remedy this problem. You can use liposomal encapsulation in which liposomal bubbles move curcumin past the digestive tract. Moreover, you can add absorption enhancers, such as piperine to boost its uptake from the intestine.

Sensitivity of Curcumin to Environmental Conditions

Environmental Sensitivity

The potency of curcumin is hampered by its sensitivity to varying environmental agents. It is a significant challenge to maintain the stability of liquid curcumin over its shelf life as it degrades upon exposure to light and high temperatures. pH changes and oxidative environment also negatively impact its effectiveness.

Solution

However, there is no doubt that you can tackle this challenge with simple steps. For example, you can incorporate stabilizers and antioxidants to increase its stability. Moreover, sophisticated encapsulation approaches shield delicate curcumin from harsh elements. Besides this, you can use opaque or amber-colored packaging to safeguard liquid curcumin formulation from light.

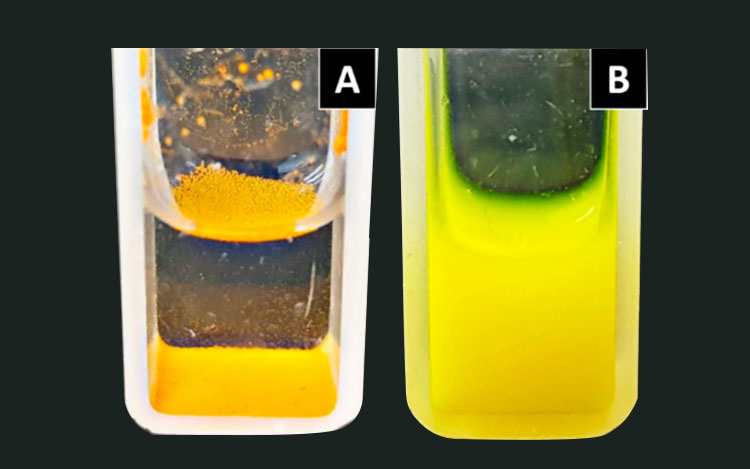

Sedimentation of Curcumin

Sedimentation of Curcumin- Picture courtesy: MDPI

It is quite a concerning issue that you may encounter over time after preparing or packaging curcumin. You may observe that your product has curcumin particles settling down at the bottom.

Solution

To overcome this challenge, you can use various emulsifiers, for instance, lecithin or polysorbate 80. These agents will keep curcumin solubilized in water. Moreover, high-speed homogenization or ultrasonication techniques are recommended to form stable solutions. Lastly, the incorporation of gelling agents or viscosity modifiers is vital in improving the suspension of particles.

Earthy Taste of Curcumin

Taste problem- Picture courtesy: 1-2 Taste EU

Let’s be real- curcumin has an earthy or slightly bitter taste when consumed raw. Hence, a bitter-tasting liquid formulation isn’t a hit among consumers.

Solution

This problem has an easy fix. For example, you could add flavor masking agents, such as natural fruity flavors, artificial flavoring agents, or sweeteners (stevia) during liquid curcumin manufacturing. Also, the encapsulation technique is favored by manufacturers because it stops curcumin from coming in direct contact with taste buds. Essential oils could be included in preparation to improve the flavor profile of these supplements.

Conclusion

From slicing roots, extracting curcumin, and solubilizing it in water to precisely filling liquid drops in a sleek bottle, each step in liquid curcumin manufacturing has its own piece of equipment to facilitate seamless workflow. These machines are the driving force behind liquid curcumin manufacturing and lend you a hand to reach your desired outcomes. Interested in investing in liquid curcumin manufacturing or planning to change your liquid curcumin production setup? Then click on the link below to get amazing offers on high-quality supplement manufacturing solutions. We, AIPAK Engineering, offer comprehensive services to address your complete range of machine preferences.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours