Liquid Probiotics Manufacturing: The Complete FAQ Guide In 2025

Do you know how liquid probiotics as a functional element benefit your gut? Ever-growing knowledge related to gut microbes has turned consumers all over the world to obtain advantages from available nutraceutical supplements. Liquid probiotics are integral ingredients that boost the environment of your stomach by boosting beneficial gut microbes.

In this article liquid probiotic manufacturing, we will talk about the inside processes, management, handling, and equipment involved from the raw material to its final product. So if you are a manufacturer, researcher, or a newbie in the field of production, then this is the right place for you. Because here you will get to explore a bank of knowledge that you won't find anywhere. Without wasting your time let's get started on our interactive and interesting topic.

1.What are liquid probiotics?

Liquid Probiotics- Picture courtesy: NZMP

The liquid probiotics are an active media of a live bacterial culture. It means that it is already in an activated state. These strains of bacterial culture are considered good bacteria and are beneficial for your gut health.

The live and active bacteria are added into the liquid with the help of lactic fermentation which helps in the growth and fermentation process even during its packaging. Lacto fermentation is the procedure that helps in the formation of lactic acid as a byproduct. Consequently, the bacterial cultures live in an acidic environment when enter the acidic pH of your gut they continue the journey of fermentation in your gut health and start work within two to three hours to six hours to achieve success.

2.What is liquid probiotics manufacturing?

Liquid probiotics manufacturing- Picture courtesy: SCD.

Liquid probiotics manufacturing is the method of selecting particular strains of bacteria that are also known as ‘Health-Promoting Bacteria’, and allowing them to grow by process of fermentation. The culture starts to multiply the colonies of bacteria and then by passing through a series of processes and sterilization, the stable and concentrated by-product of bacterial strains are added and formulated in a liquid vehicle. Liquid probiotics manufacturing is a gateway to attain a stable and effective formulation with improved shelf life and protective packaging.

3.How liquid probiotics manufacturing is beneficial?

Liquid probiotics manufacturing is always considered beneficial to your firm. This is because it offers so many health benefits. Consequently, several thousands of consumers all around of world implement them into their regimens and have high market demand.

Offering a safe and quick solution

Safe And Quick Solution- Picture courtesy: One Life Foods

As compared to other dosage formulations, the liquid probiotics manufacturing products are quick to absorb and potent in results. It isn’t associated with disintegration and dissolution factors like capsules and tablets. Neither the manufacturing process is involved with coating and related steps. Thus, it is easy to make and easy to administer with rapid and effective response.

Providing supplements easy to consume

Providing supplements easy to consume- Picture courtesy: Women Health

The purpose and prime benefit of liquid probiotic manufacturing is to provide you with an effective dose with flexible consumption. Indeed, tablets, capsules or other formulations are quite difficult to take for some people such as kids and the adult population. When it comes to liquid probiotics, this is an excellent option for such generations and people with difficult swallowing issues.

High efficiency and potency

High efficiency and potency- Picture courtesy: Optibac

As compared to other supplements, liquid probiotics manufacturing provides you with the solution for excellent efficacy and potency in your gut flora. It reaches instantly without taking extra time and offers beneficial effects without compromising the active doses.

Maximum bioavailability

Maximum bioavailability- Picture courtesy: Next Gen

Another benefit behind liquid probiotic manufacturing is its bioavailability ratio. Liquid probiotics tend to reach the gut environment in a hurry to show their work without interacting with other entities or secretion of GIT. Therefore, your body gets a good chance to avail more good bacteria to benefit you quickly.

Nicer taste with no fuss for dose-making

Nicer taste & accurate dose

Today’s world is busy! Everyone is trying their best to get benefits from supplements in no time. Liquid probiotic manufacturing not only gives you exact doses but with improves taste without any odor or tasteless effects. The positive point is that whatever the manufacturer claims for quality, dose, or potency, you will get the guaranteed stuff.

4.At what industrial sectors on liquid probiotics manufacturing take place?

Liquid probiotics manufacturing can be applied in certain industrial sectors such as:

Food and Beverage Industry

Food and beverage

Liquid probiotic manufacturing is mainly taking place in food and beverage industries, and they are known to be the primary producers of relevant formulations. Food and beverage products such as yogurt, cheese-related products, flavored yogurt, and related dairy drinks including milk, lassie, etc. are included with energy drinks that are directly related to boosting digestive immunity as well as your overall health system.

Nutraceutical Industry

Nutraceutical Industry- Picture courtesy: Tropicana Essentials

Whenever you are thinking about having beautiful hair, attractive skin, and overall looks of your well-being, nutraceutical products come to your mind. Liquid probiotics manufacturing is the major sector of the nutraceutical industry that helps in making formulations for the maintenance of your internal damages and boosts body performance. In the nutraceutical industry, liquid probiotic products come in combination with various other trace elements, minerals, and vitamins, thus you can get an energy bunch with amazing taste.

Pharmaceutical Industry

Liquid probiotics in the pharma industry

The medicinal-related manufacturing mainly occurs in the pharmaceutical industry. Liquid probiotics manufacturing in pharma is needed to meet the demand for treatment of various diseases related to your gut such as irritable bowel syndrome, ulcerative colitis, diarrhea, and vomiting, and strengthening of your gut microbe, dealing with various inflammatory syndromes, etc.

Animal Feed Industry

Animal Feed Industry

In the animal feed industry, liquid probiotics manufacturing formulations are required that help in the enhancement of gut flora of the animals including, cows, poultry, etc to offer quality outcomes such as healthy milk, eggs, and meat along with healthy animals. Also, it is also used for pet lovers and their pets for a healthy gut.

Cosmetics and Personal Care Industry

Cosmetic industry- Picture courtesy: MYLCK

Liquid probiotics manufacturing is required in the cosmetics industry for formulation and is gaining popularity day by day. Various skin-related serums, sprays, and tonners in liquid probiotic formulations when you apply them over your skin help in reducing skin-related problems. For example, dermatitis, acne, and e enhancing your skin texture with an extremely noticeable glow.

Biotechnology and Laboratory Testing

Biotechnology and Laboratory- Picture courtesy: Henry Bloom

Liquid probiotics manufacturing samples are always required for testing and assessment in the biotechnology and R&D sectors. The purpose of doing this is to evaluate the activity of strains, improvement of probiotics when in combination with other strains, etc.

5.What are the series of steps involved in liquid probiotics manufacturing?

In the burgeoning era of well-being and healthy lifestyle, everyone is urged to know liquid probiotics. Moreover, how a certain strain of bacteria can improve your immunity, and the related plethora of your physiology is also important to explore. Firstly, we will talk about how these little health powerhouses are prepared. Let's look into the certain series of steps involved with liquid probiotics manufacturing.

Strain Selection

Strain selection- Picture courtesy: Medical News Today

The first step of liquid probiotics manufacturing is the choosing right strain that benefits you. The bacterial strain must be resilient in nature and should be capable of surviving in multiple climaxes. Moreover, the selection depends on the available probiotics pool which is mainly designed by various research studies, testing, and various trials.

Identification

Identification- Picture courtesy: Bio K+

Liquid probiotics are mainly distinguished by their genus, strain, species, or sub-species. For instance, Lactobacillaceae family strains Bacillus, Enterococcus, Streptococcus, and Escherichia. Side by side, many products were manufactured by using the strains from the Lactobacillaceae family which is known as the Lactobacillus genus before 2020 as the specific genus was redesigned using biotechnology.

We have mentioned some commonly used liquid probiotics strains used commercially

| Genus | Species | Subspecies | Strain Designation | Strain Nickname |

| Lacticaseibacillus(formerly Lactobacillus) | rhamnosus | None | GG | LGG |

| Bifidobacterium | animalis | lactis | DN-173 010 | Bifidus regularis |

| Bifidobacterium | longum | longum | 35624 | Bifantis |

| Streptococcus thermophilus | Bacilli | - | - | S. thermophilus |

Table courtesy: NIH Office of Dietary Supplements

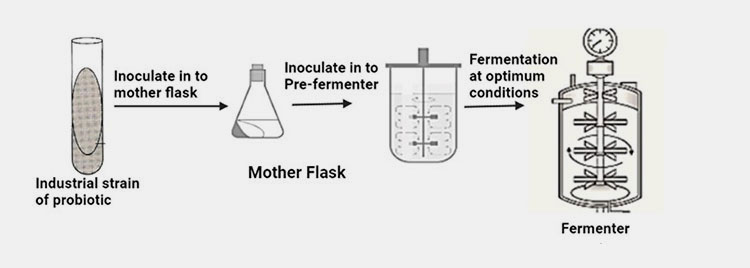

Cultivation and Fermentation

Cultivation and Fermentation- Picture courtesy: FPPN

This is the step where the selected bacterial strain cultivates and expands itself to induce a greater growth level. The nutrient-rich media is provided with controlled temperature and environment. The process in other words known as ‘fermentation’. Have you ever fermented yogurt? This is also a kind of cultivating probiotic under optimized growth conditions. The process mainly takes place in 24 to 72 hours considering warm temperatures that range from 37 to 43°C for ideal results.

You should keep in mind that every strain refers specific temperature to grow such as Bifidobacteria favors 37 to 41 °C, moreover, strains used in yogurt are mainly suitable for cultivating under 42-45°C, and strains like Lactobacillus plantarum expand around 40 °C.

Harvesting

Harvest- Picture courtesy: NutraIngredients

When the bacterial culture is cultivated and fermented completely, it should contain the live culture of the probiotic that contains active bacterial strain. Therefore, you need to harvest them first. This means you can separate the bacterial strain from the medium. Once you separate the bacterial strains, the second step is to concentrate them.

Concentration

Concentration- Picture courtesy: Livestrong

It is indeed in a semi-solid form that has to be in powdery form. For this, you need to use the various available methods. For example:

| Freeze Drying

This is also known as a lyophilization drying method that utilizes drying under vacuum pressure. First, the formulation is frozen and by inducing the vacuum the ice is eliminated into gas directly that gets around the liquid state. |

|

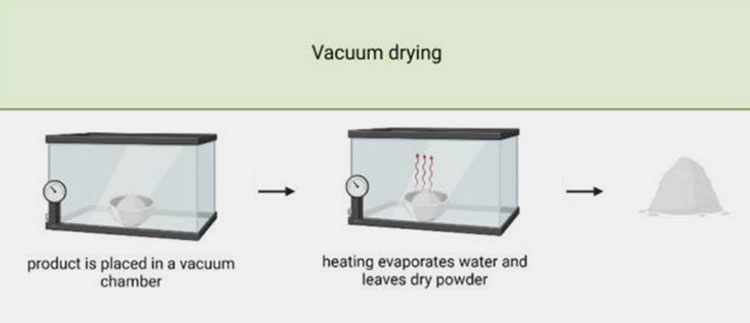

| Vacuum Drying

Here the pressure reduction takes place causing a lowering of boiling point. When it reduces the temperature the evaporation process takes place easily with the help of vacuum pumping units. |

|

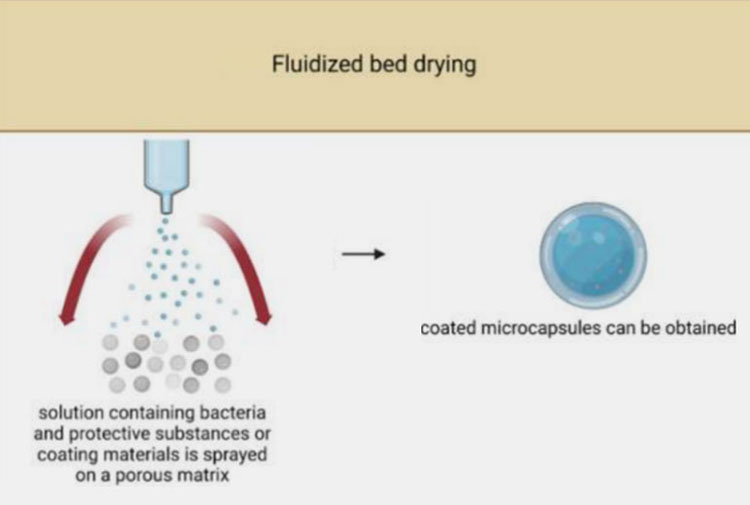

| Fluidized Bed Drying

The drying takes place through the stream of heated air that suspends the formulation particles to stay in the air and ensures rapid dryness. |

|

| Spray Drying

In this method, the liquid is converted into the finest droplets that are exposed to a hot air stream to dry and obtain the powdery substance. |

|

Formulation

Formulation- Picture courtesy: Foodsure

After harvesting and concentrating the probiotic substance, this is the time to formulate liquid probiotics. Mixing is the prime tool that helps liquid probiotics manufacturing to produce an effective and stable product. In many instances, manufacturers mix the probiotics and prebiotics to enhance symbiotic effects.

Water Administration

Water administration- Picture courtesy: Britannica

For the liquid, purified water is used for homogenizing effects, it can be prepared either with fruit juices or with dairy liquids. Remember to use purified water to maintain the activity of the prebiotic formulation with improved shelf life and potency.

Probiotics Doses & Mixing

Probiotics Doses & Mixing- Picture courtesy: BEV.Net.com

According to research designed the probiotics concentration in liquids are used around 10 6 to 10 12 CFU per ml, but it is also depending on the strain to strain. The low shear mixing takes place to form a homogenized solution well properly mixing of the ingredients such as sweeteners which is mainly used approximately 60% weight by volume.

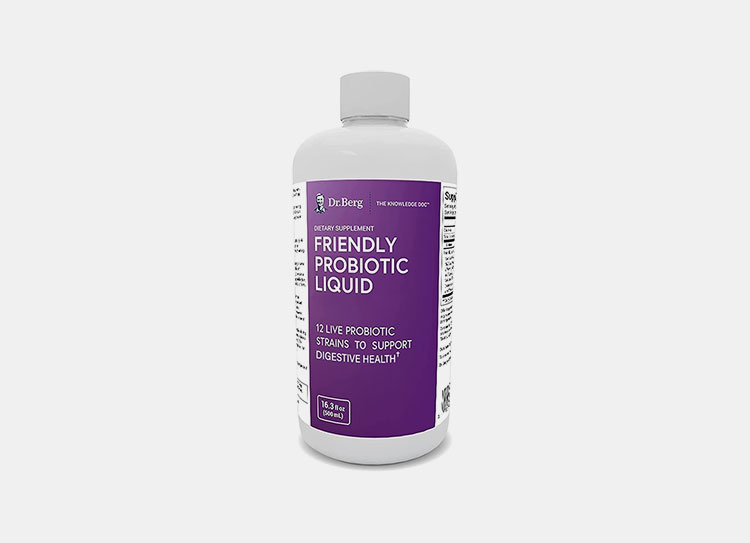

Packaging

Packaging- Picture courtesy: New beauty

Once the liquid probiotics formulation is processed, the assigned packaging materials are subjected to a filling section. The liquid formulations are packed in bottles, vials with droppers, etc. thus final product is ready to serve you.

Cold Storage

Cold Storage- Picture courtesy: Omni- Biotic

Once the packaging and related formalities are done with liquid probiotics formulation, the essential step to be carried out is to store them at an appropriate temperature. This is recommended to maintain the temperature for storage at about 4°C. The reason behind this is that it helps in the viability of the culture.

Stability testing for formulation

Testing- Picture courtesy: Probiotic

No formulation can be finalized without conducting the stability tests. The purpose of certain tests is to assure the customers and distributors have the know-how and at what temperature, pressure, and physical conditions are suitable for stable products. Therefore, the manufacturer first performs the test and claims it. There are various tests including a water activity test (which implies the CFU count that persists in the efficacy of liquid probiotics with time), a heat test (which entails how much heat is not desirable for the viability of the product), an invitro survival test, etc.

Labeling & Compliance

Labeling and Compliance- Picture courtesy: ISAPP

This is the final step where you apply a label over the product telling what specific strain was used in the formulation, the number of CFUs used, the manufacturing batch, date, nomenclature, what temperature is suitable for storage of the item, etc. The next important information included the serving size, and the supplements quantity such as carbohydrate, minerals, and protein concentrations. Remember that each step and prepared product claims must be astringent to regulatory bodies such as the FDA, WHO, and particular local regulatory standards.

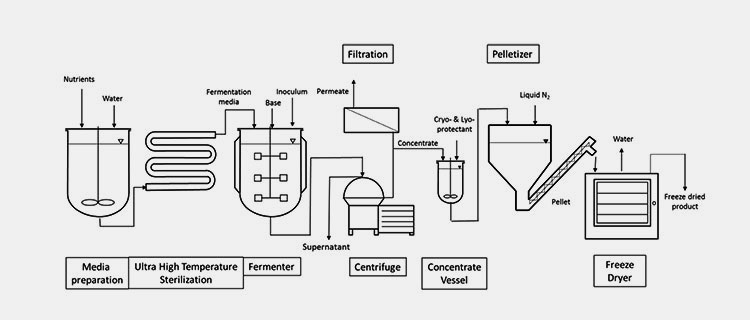

6.What important sequences of machinery are involved in liquid probiotics manufacturing?

Liquid probiotics manufacturing is not a simple process rather it needs the involvement of various equipment. Each equipment has its own significance and skipping any of them can cause failure in production. Check the following list of machineries:

Protocol Sketch of Liquid Probiotic Manufacturing- Picture courtesy: mdpi

Media Preparation Mixing Machine

AIPAK Vacuum emulsifying mixer

The vacuum emulsifying mixer is the first step of manufacturing where the mixing of ingredients linked in the making of liquid probiotics is subjected. For example, powder probiotics, sweetening agents, and flavoring agents may be colorants. The machine perfectly fuses and blends the ingredients ensuring unmatched homogenizing effects with superior media preparation.

Ultra-High-Temperature Sterilization

Ultra-High-Temperature Sterilization

An ultra-high temperature sterilization tunnel is facilitated with the innovative articulation of circulatory pipes. The structure is used for circulating heated air required for the removal of impurities present in the formulation ingredients, materials used in manufacturing as well as packaging substance. The production process is composed of pre-heating, and ultra-hot drying followed by the sterilization principle.

The working of the unit is based on laminar flow with ultra-disinfection properties used for the elimination of pyrogen and other related microbial agents. The typical temperature used for tools and materials used in manufacturing probiotic liquids ranges from 250°C to 350°C or 482°F to 662°F.

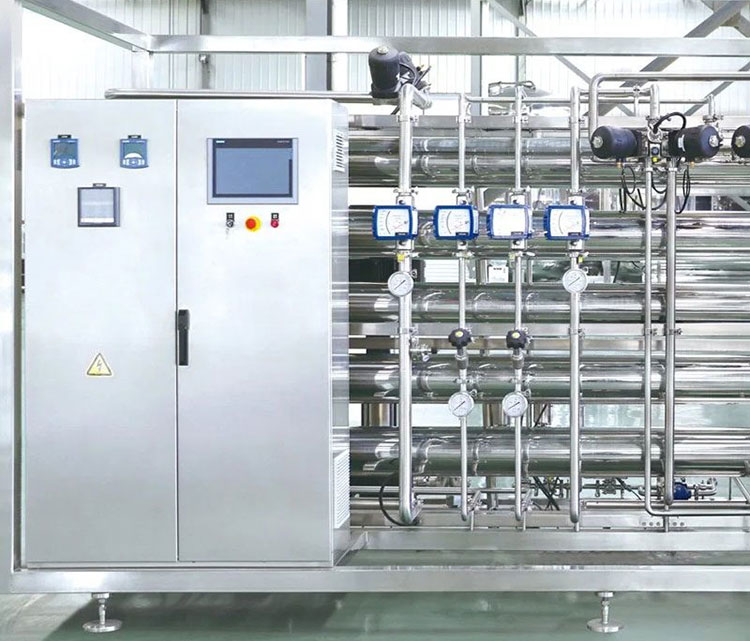

Water Treatment Plant

AIPAK Engineering Water Plant

This is an essential machine required for purified water compliant with FDA regulations. The machine provides water after extensive treatment which is composed of multiple stages. For example, coagulation, flocculation, sedimentation, and filtration followed by disinfection. Thus, the form water is safe and cleaned from impurities.

Fermenter

Fermenter

An important machine that is responsible for the fermentation process. This is the process that helps in the induction of fermentation of probiotics in a controlled environment. It is also known as a bioreactor and fermenter. The specialized equipment needed for cultivating yeast, bacteria (good bacteria), and related microorganisms such as fungi, related to research.

The unit is designed with a double-jacketed vessel with feeding pumps, a sensor, and an agitator that helps in the uniformity-controlled process and ensures a quality fermentation process.

Centrifugation Machine

Probiotic centrifugation machine- Picture courtesy: GEA

Once the fermentation process happens, centrifugation is required to separate the bacteria from the broth of fermentation. Therefore, the machine helps in extracting good bacteria in the living culture. This is a highly cleaned machine and sterile as it can be cleaned and sanitized using CIP and SIP processing thus ensuring no risk for cross-contamination of various other formulations. The machine is ideal for separating probiotic bacterial as well as postbiotics substances which is needed for other applications.

Dryer Machine

You can't ignore the drying machine when it comes to subjecting liquid probiotic manufacturing. Here we go, there are some basic drying machine included in the drying process.

| Vacuum Freeze Dryer

|

A vacuum freeze dryer is also known as a lyophilization machine which helps in the elimination of moisture or water content from the separated bacterial culture to enhance its shelf life and integrity. The machine is designed with a vacuum chamber and heated trays required for induction of sublimation.

The work takes place in three basic steps including freezing of bacterial culture, sublimation, and final drying. This machine gives a milder environment therefore probiotics released are shown to have more stable and greater survival rates. |

AIPAK vacuum freeze dryer |

Liquid Probiotic Filling Line

AIPAK Engineering Liquid Probiotic Filling Line

The liquid probiotic filling line helps in processing the series of work including bottle supplying, and liquid probiotic filling with specialized anti-dripping nozzles, once filled are treated with the application of firm and automatic cap locking. The game continues as the hot melting sealing properties ensure the firm securing of the formulation; thus, the one-stop solution imparts significantly in finishing all major responsibilities effectively.

7.Is liquid probiotics manufacturing better than solid probiotics?

Liquid probiotics manufacturing VS solid probiotics has always discussed as a debate for many years. But yes, it's all about what manufacturing product benefits you the most. Frankly, many experts believe that liquid is far better than solid. Please see below the main differences.

Solid VS liquid probiotics

| Nutrients | When it comes to talking about solid probiotic manufacturing, it offers you pills, capsules, and tablets when you take them some of their nutrients get sacrificed due to harsh stomach environments. Therefore, the times it reaches the intestine some of them are absorbed while some are compromised. Research has confirmed that solid probiotics offer 5 to 15% lower absorption of nutrients than liquid probiotics manufacturing products. |

| Price | You pay for products obtained from solid probiotics manufacturing, but it is probably higher than the positive effect you get from liquid. This is why it is recommended as you get a real impact in a shorter time. |

| Preparation | The solid probiotics manufacturing requires many steps, including filtration, grinding, granulation, mixing, etc. Moreover, in the case of capsules, pills, and tablets, you will require with coating. If ignored, the supplements won't be able to reach the active site. So it is hard to make solid probiotics and preserve the nutrients.

On the other side, liquid probiotics manufacturing isn’t involved with nasties. Here you just need to focus on liquid formulation, mixing, and packaging. Here you do not go for excipients, bulking agents, coating, etc. |

| Health Supporter- Solid or Liquid Probiotics Manufacturing | As compared to solid, liquid probiotics manufacturing formulation is all about efficacy. It supports your health more and your body only takes a few minutes to reach the active site than solid probiotics which take around 30 minutes. So, more nutritional and health support you get from liquid probiotics. |

8.What are available packaging types of options for liquid probiotic manufacturing?

Liquid probiotic manufacturing is mainly expanded with large packaging options. We have provided brief information about all types in the below table.

| Ampoule | For small-dose applications and single-dose probiotic formulations, ampoules are used. They are either made up of glass and plastic. This packaging type is typically used for traveling purposes or other and occupies less space with easy administration. The hermetically sealed ampoules that can be utilized as a single serving while remaining are suggested to be discarded. |

Ampoule |

| Bottle | This is indeed an ideal option if you want to use liquid probiotics for regular consumption. It is mainly designed with either a cap or dropper cap that helps in the taking of a particular dose easily. As compared to vials and ampoules, the bottle may store liquid probiotics in large volumes. |

Bottle |

| Vials | The vial can be used for more than one-time usage and may be able to store a greater volume of liquid probiotics. They are also sealed firmly to preserve freshness throughout their storage time. The material of the bottle can either be plastic or glass which is mainly amber color to protect the formulation from photodegradation. |

Vial |

| Gallon | The liquid probiotics in bulk storage are only possible with gallons. This is mainly required for research, organizational, clinical, and pharmaceutical applications. This is a great option when you need to distribute liquid probiotics in various sectors, as it can store multiple liters of formulation easily. |

Gallon |

9.What would be the shelf life of liquid probiotics manufacturing?

Shelf life- Picture courtesy: Culturelle

This is notably observed that liquid probiotics manufacturing products are associated with limited or shorter shelf life. Therefore, many of them are stored in a controlled condition specifically after opening the packaging. The approximately ideal life of liquid probiotics is remarked for six months to one year. Still, they depend upon strains and packaging conditions. Because the living bacteria require controlled conditions to perform the ideal activity and stability.

However, in some cases, if the storage is done with air-tight sealing with more astringent parameters, it can be extended to more than one year, if keeping temperature reduced with no modulation in light.

10.What are the available dosage sizes of liquid probiotics manufacturing?

Doses Of Liquid Probiotics

The CFU or colony forming unit is a measuring unit that tells you the dose size of liquid probiotics and their availability. It has ranges which lie between one to 10 billion in each administration and it can be exceeded more than fifty billion CFU as well. The CFU mainly tells you the concentration of vial good bacterial cells present in the formulation.

Commercially, the liquid probiotic manufacturing dosage is designed to have one to ten billion to 50 billion CFU per dose. However, your physician recommends five to ten billion CFU/day for children and ten to twenty CFU/day for adults. For children, the available doses are administered easily by simply utilizing the dropper to measure the dose of a specific concentration.

11.What are the major enemies of liquid probiotics manufacturing storage?

Nevertheless, the liquid probiotic manufacturing formulations are sensitive and delicate in nature. If their storage is not handled properly it can impose risks and can’t effectively work in your gut. Research studies confirm that if storage is not properly maintained; the liquid probiotic can decrease its CFU or vial organisms up to 85%. The major causes of declining the activity are mentioned below:

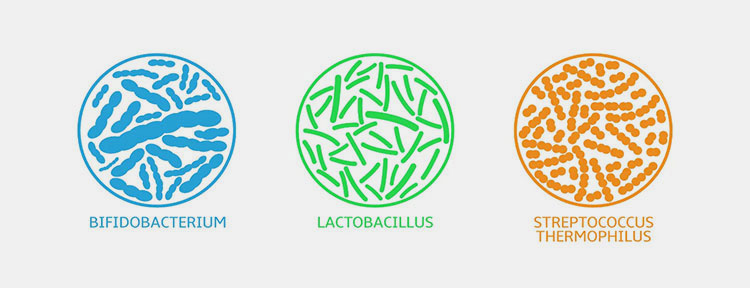

Heat Exposure

Heat

Storing the liquid probiotic manufacturing products at a cold temperature can help in the extended shelf life. In some cases, the probiotics do not need cold temperatures, but they must be in a cool and dry environment. The suggested temperature is 70 degrees F, above this limit, the principal activities can be reduced, and it can't withstand for long. Therefore, liquid probiotic manufacturing packaging must be done in a way that can resist heat and protect the formulation.

The common heat-sensitive probiotic strains are Streptococcus, Lactobacillus, and Bifidobacterium; therefore, you need to be alert and keep them refrigerated for storage purposes. Side by side, at 115°F, there will be no more viability rate of bacteria as it directly kills them. Therefore, you should not expose them to high heat.

Moisture

Moisture- Picture courtesy: Feldco

Moisture is an enemy of various formulations as it can catalyze unwanted reactions and can affect stability. In the case of moisture, it can stimulate the probiotic bacteria before it reaches your gut thus affecting the properties and efficacy. Therefore, the storage conditions must be around having a relative humidity of less than 20% and above 50% RH can directly impose detrimental effects. The packaging of liquid probiotic manufacturing must be moisture-proof material to resist unwanted factor interactions.

Conclusion

Liquid probiotics manufacturing is a well well-documented and regulated process that takes place under astringent regulatory standards and handling. However, all the types of machinery used must be of absolute quality to prevent downtime and enhance the excellent manufacturing process. In this article, we tried our best to describe and talk about each process involved in the system. If in case you have any questions in mind; contact the AIPAK Engineering team to get the right and quick answer. Also, do check our products and top-notch equipment series related to liquid probiotics manufacturing. We assure you that you will promising solutions with us. Connect us now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours