Protein Liquid Supplements Manufacturing: The Complete FAQ Guide In 2025

More and more young people are prone to take a closer look at the labels when choosing nutritional supplements. In addition to paying attention to the calorie content of food, protein content has also become an important criterion for them to choose food. In addition to protein powder, protein liquid supplements have also become the main choice for people at present.

Do you know how protein liquid supplements are produced? What machines will be involved? Do you have any requirements for producing protein liquid supplements? Next, let’s take a look at the complete FAQ guide on protein liquid supplements manufacturing.

1.What Are Protein Liquid Supplements?

Protein Liquid Supplements -Sourced: Netrition

Protein liquid supplements are a type of health supplement that can improve human health. The development of protein liquid is very rapid in the field of dietary supplements or health products.

With the continuous evolution of the protein food, the innovative form of liquid protein is gradually becoming the new favorite of the market. Its unique properties and convenient way of consumption make protein liquid show great potential in meeting consumers’ needs for health and nutrition.

2.What Are the Benefits of Protein Liquid Supplements?

Why are many people taking protein liquid supplements now? The reason lies in its many benefits.

High absorption rate

High Absorption Rate - Sourced: Naked Nutrition

Compared with solid protein products, liquid protein does not require complex digestion and decomposition processes, and can provide the body with the necessary protein nutrition faster, promote muscle growth and repair, and enhance the body’s self-protection ability.

Beauty and skincare

Plant protein contains various nutrients, and appropriate consumption by the human body can inhibit free radicals in the body, which can delay aging, beautify and nourish the skin, making it smoother, more delicate and elastic.

Regulating immune function

Regulating Immune Function - Sourced: ER of Texas

Protein in the human body can provide various amino acids, reduce plasma cholesterol levels, and supplement the body with necessary energy, thereby regulating immune function.

3.What Are the Different Types of Protein Liquid Supplements?

Have you ever taken protein liquid supplements? What type of medication are you taking? To be honest, protein liquid supplements can be used in different industries and have different effects.

Protein drinks

Protein Liquid Drinks - Sourced: Parentgiving

After drinking protein liquid drink, it can supplement the body with the necessary protein and to some extent assist in enhancing one's own immunity, making it suitable for people with weakened immunity to drink.

Proteinliquid with vitamins

Protein liquids are rich in vitamins, which have the characteristics of easy absorption, convenient use, stable composition, good taste, and wide applicability to a wide range of people.

Protein liquid supplements for sports nutrition

Protein Liquid Supplements For Sports Nutrition - Sourced: Eric Favre

In the field of sports nutrition, it is a must-have for athletes, helping them quickly recover their strength after high-intensity training and promoting muscle growth.

Protein liquid supplements for sleep

Protein liquid supplements can improve sleep quality, but the specific treatment plan should be selected according to the causes and severity, and medication should be taken under the guidance of a doctor to avoid adverse effects caused by blind medication

4.What Is the Protein Liquid Supplements Manufacturing Process?

Protein liquid supplements have similarities with ordinary liquid production processes, but some steps are still different.

Preparingraw materials

Selecting whey protein from high-quality milk sources as raw materials to ensure purity, freshness, and pollution-free properties. As you can know, liquids cannot do without water, so it is necessary to purify the raw water.

Mixing

Mixing protein raw materials with other ingredients, such as sugar, essence, vitamins, minerals, etc. During the mixing process, attention should be paid to hygiene to avoid other impurities from entering and affecting the subsequent processing of the product.

Homogenization

By physical means, large particles in liquid materials are broken down into small particles and evenly dispersed in the medium. After homogenization, the fat particles in protein are refined, avoiding the problem of fat floating up and making the texture of protein more delicate.

Filling

Filling - Sourced: Antonio Mengibar

Filling the formulation into a suitable container and seal it. Common packaging materials include glass bottles, plastic bottles, etc., which should be selected according to the characteristics and usage requirements of the formulation

Labeling

Labeling or labeling on protein liquid supplements is primarily used to provide relevant information about the product.

5.What Machines Are Used in Protein Liquid Supplements Manufacturing?

What machines are involved in the production of protein liquid supplements?

Purified water treatment equipment

AIPAK Engineering Purified Water Treatment Equipment

Using various pretreatment methods during the raw water treatment stage, the purified water equipment ensure that the raw water meets the expected indicators and thus meets the requirements of subsequent purification processes. These pretreatment methods mainly include removing suspended particles, organic matter, heavy metals, colloids, microorganisms, and free residual chlorine from raw water

Mixer

AIPAK 3D Motion Mixer

The 3D motion mixer places the raw materials of liquid protein supplements into a mixing chamber or container, and uses the motion of the stirring device to stir, push, and collide the materials, thereby achieving uniform mixing of the materials. Different types of mixers may adopt different mixing methods and mixing chamber designs to meet different mixing needs.

Homogenizer

AIPAK Homogenizer

Homogenizer is an efficient material processing equipment, which has the advantages of good homogenization effect, improved production efficiency, wide processing range, and easy operation.

The fluid flow velocity inside the homogenizer increases, and the shear stress increases, resulting in an increase in the flowability of particles and a more uniform dispersion of materials. The centering effect during the homogenization process causes the material to undergo multiple shearing and other effects within the homogenizer, further improving homogenization.

Liquid filling machine

Due to the different forms of packaging, the packaging machines involved are also different.

(1)Doypack machine

AIPAK Doypack Machine

The doypack machine uses advanced sensors and control systems to accurately control various parameters during the packaging process, such as bag size, sealing quality, etc., ensuring that each liquid protein supplements meets the specified packaging standards and improving the overall quality of the product.

(2)Bottle liquid filling machine

AIPAK Bottle Liquid Filling Machine

By precise measurement and efficient filling, the bottle liquid filling machine can ensure liquid protein supplements to enter packaging containers, such as plastic bottle, glass bottle and others, thus meeting the diverse needs of the market. Users can choose the filling quantity based on their production capacity to determine the number of filling heads. The touch operated color screen can display production status, operating procedures, filling methods, etc.

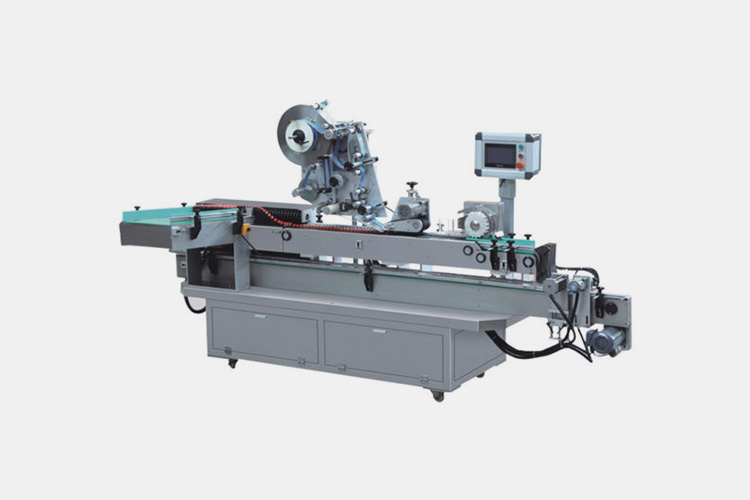

Labeling machine

AIPAK Automatic Labeling Machine

Automatic labeling machine is a specialized equipment for product labeling, which accurately attaches labels to products through automation, improving production efficiency and labeling quality. In addition, the conveyor belt can also be equipped with a coding machine to meet the need for information printing of products before or after labeling.

6.What Types of Packaging Can Be Used for Protein Liquid Supplements Manufacturing?

Protein liquid supplements are becoming increasingly popular among consumers due to their healthy and nutritious properties. However, the choice of packaging materials for such supplements is also an important factor affecting their market performance and consumer acceptance.

PET plastic bottle

PET Plastic Bottle - Sourced: Packaging Strategies

PET plastic bottles are one of the most commonly used packaging materials for protein liquid supplements. It is lightweight, not easily breakable, and has good transparency, making it easy to display the color and texture of supplements. In addition, PET plastic bottles also have good barrier properties, which can effectively protect the quality of beverages.

Metal cans

Metal Cans - Sourced: GoSupps.com

Metal cans are mainly used for large capacity packaging, with the advantages of good sealing, moisture resistance, light resistance, and long shelf life. Metal canned protein liquid supplements have higher stability during transportation and storage, which can effectively extend the shelf life of products.

Glass bottles

Glass Bottles - Sourced: Freepik

Although glass bottles are not as portable and cost-effective as PET plastic bottles and metal cans, their environmental friendliness, recyclability, and high-end appearance are still favored by some consumers. Protein liquid supplements in glass bottles are commonly found in the high-end market and are suitable as gifts.

Carton packaging

Carton Packaging - Sourced: Amazon

Paper boxes can be customized according to different market demands and product characteristics. From shape, size to printed patterns, they can be flexibly adjusted to meet the aesthetic and practical needs of different consumers. Compared to traditional plastic packaging, the paper material used in carton packaging is easier to degrade and recycle.

Doypack

Doypack - Sourced: Makeup

The doypack is easy to carry and use, allowing consumers to directly drink or squeeze out protein liquid through the nozzle, avoiding the hassle of using other containers. In addition, doypack can avoid direct contact with products, reduce the risk of contamination, and maintain product hygiene.

7.What Regulations Should Protein Liquid Supplements Manufacturing Follow?

The production of protein liquids must strictly comply with relevant regulations to ensure that the products meet the relevant requirements.

FDA standards

FDA Standards - Sourced: LinkeIn

One of the obstacles to entering the US market is product compliance, and FDA certification is key to ensuring that products comply with US regulatory standards. The production of protein liquid supplements requires FDA certification.

The FDA’s primary concern for medical devices is safety. Manufacturers need to provide sufficient data and evidence to demonstrate that their products are safe for their intended use and that the risks are acceptable. This includes assessing and managing potential risks to ensure that the product does not pose a risk to patients or users during use.

GMP standard

GMP Standard - Sourced: GOL Solution

GMP requires protein liquid supplements to have a reasonable production process, good production equipment, advanced scientific production procedures, sound quality control, strict operating procedures, and a finished product quality management system. Through correct control of their production process, the goal is to achieve comprehensive improvement in nutrition and safety.

8.What Testing and Quality Assurance of Protein Liquid Supplements?

In the supplement industry, it is necessary to strictly control the quality of products and conduct rigorous testing to ensure that they meet the highest standards.

Ingredient testing

Ingredient Testing - Sourced: Beaconpoint Labs

The protein determination process is very simple, first test the blank solution, and then directly test the protein. This makes the results appear very unstable. The direct protein quantification method is suitable for testing relatively pure and single component proteins.

Compared to colorimetric methods, UV direct quantification is faster and easier to operate; But it is susceptible to interference from parallel substances, such as DNA interference; In addition, low sensitivity requires a high concentration of protein.

Stability testing

Regularly measure the content of recombinant collagen in the product using high-performance liquid chromatography (HPLC) and other methods to observe whether it degrades or changes over time. Analyze other chemical components that may affect stability based on product characteristics.

9.What Should Be Consider When Choosing Protein Liquid Supplements Equipment Manufacturer?

Choosing the right machine manufacturer is half the battle, so you need to be cautious when choosing a protein liquid supplements equipment manufacturer.

Service quality

Service Quality - Sourced: Trengo

Protein liquid supplements equipment manufacturer needs to provide professional services, including technical support, after-sales service, marketing promotion, etc. We need to pay attention to whether the manufacturer has a complete service system, and whether the service quality and response speed meet customer needs.

Visiting and inspecting

Before choosing a protein liquid supplements equipment manufacturer, it is recommended to visit and inspect the manufacturer’s production site, research and development center, etc. to understand the actual operation and management level of the manufacturer. At the same time, it is also possible to communicate with the employees and management of the manufacturer to understand their professional abilities and attitudes.

Product quality

Product Quality - Sourced: The Salpila

Product quality is the core element for measuring protein liquid supplements equipment manufacturers. You can understand the quality of a manufacturer’s products by checking their past production records, user reviews, and reports from third-party evaluation agencies. In addition, manufacturers should provide detailed information on product ingredients, efficacy, and consumption methods to enhance consumers’ trust in the product.

Collaboration case

Understanding past cooperation cases of manufacturers can help you assess their overall strength. Excellent health product processing manufacturers should have rich cooperation experience and have provided processing services for multiple well-known brands. By examining the cooperation cases of manufacturers, you can understand their production capacity, quality control ability, and market competitiveness.

10.What Future Development of Protein Liquid Supplements?

Liquid protein, as an important force in food innovation, is increasingly favored by the market. Its convenient way of consumption and unique nutritional value provide consumers with new choices on the path of pursuing a healthy lifestyle.

The market size continues to expand

According to Mordor Intelligence data, the global protein supplement market has reached $25.2 billion in 2023 and is expected to continue expanding at a compound annual growth rate of 8%.

As an important structural component and basic nutrient of human functional tissues, protein deficiency not only affects physical development, but also has adverse effects on the normal operation of the immune system. Therefore, the global protein craze has persisted for a long time, especially in European and American countries where it is thriving.

Increasingdemand for protein liquid supplements

Increasing Demand for Protein Liquid Supplements - Sourced: Business Insider

Affected by the epidemic, people’s demand for nutrition, health, and immune enhancement has significantly increased, which further promotes the prosperity of the protein food market.

The main factor driving the significant expansion of the global protein water market is the increasing popularity of protein supplements among health conscious consumers. The continuous increase in the number of athletes and fitness enthusiasts worldwide is another key factor driving the growth of demand in this market.

Conclusion

Protein liquid supplements have multiple benefits and are favored by many people. The production of protein liquid supplements involves many processes and machines. After reading this article, have you gained some understanding of the production of protein liquid supplements? If you have any further questions, please feel free to contact AIPAK Engineering at any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours