Ibuprofen Suspension Manufacturing: The Complete FAQ Guide In 2025

Does ibuprofen suspension remind you of your childhood? Do you know there is a complicated manufacturing process behind a simple bottle of ibuprofen?

Indeed! Behind this apparently modest product lies an enthralling processing operation, mixing chemistry, strict quality testing, and state-of-the-art pharmaceutical technology. Ibuprofen suspension manufacturing involves selecting the right combination of pharmaceutical ingredients with effective therapeutic potential, dispersing, homogenization ingredient blends, and honing the flavor and thickness of suspension.

Are you intent on unraveling hidden secrets about ibuprofen suspension manufacturing? Do you want to learn how this widely used pharmaceutical product attains maximal therapeutic potency? Then let’s explore together diverse aspects of ibuprofen suspension manufacturing from formulation strategies to processing steps and more in this FAQ guide

1.How do you define ibuprofen suspension manufacturing?

Ibuprofen Suspension Manufacturing- Picture Courtesy: Helix Pharma

It is the processing and manufacturing operation in which a liquid preparation with active ingredients is developed. This process is carefully managed to deliver accurate and potent doses of ibuprofen to the patients.

In this procedure, normally fine particles of pharmaceutical component ibuprofen and other excipients are dispersed in a liquid phase- generally water- to generate a uniform, stable, and flavorful suspension for alleviating muscular aches, headache, ear pain, dental pain, and fever.

In short, ibuprofen suspension manufacturing is an operation in which bitter and water-insoluble drug is transformed into liquid medication that is not only easy to take but also has the desired healing effect.

2.What are the ingredients and excipients in ibuprofen suspension manufacturing?

People are concerned about what are they consuming and ibuprofen is no exception to this. Pharmaceutical manufacturers cautiously choose active ingredients as well as excipients to deliver stable and effective ibuprofen suspension to their customers. These ingredients have a specific role in ensuring the therapeutic efficacy and stability of ibuprofen suspension.

For your information, we are detailing the ingredients and excipients in ibuprofen suspension manufacturing.

Active Ingredients

Active Ingredients- Picture Courtesy: Oprah Daily

The chief active pharmaceutical ingredient in ibuprofen suspension is ibuprofen. Usually, this compound (RS)-2-(4-(2-Methylpropyl) phenyl) propanoic acid is crushed into a fine powder before mixing. It is poorly water-soluble but readily dissolves in acetone and alcohol.

It is excellent in treating mild to moderate level pain and also decreases fever in both adults and young kids. It also serves as an anti-inflammatory agent and lowers arthritis-related inflammation.

Excipients

Excipients- Picture Courtesy: SMP Nutra

Just like tablets or capsules, excipients are also incorporated into the ibuprofen suspension. Why? Because they have different roles in boosting stability, safety, palatability, and quality of medications. Let’s read about integral excipients present in ibuprofen suspension manufacturing one by one:

Suspending Agents

Suspending Agents- Picture Courtesy: EasyBuy Ingredients

Do you know how uniform distribution of ibuprofen particles is achieved? It is by stabilizing or suspending agents. They evenly suspend and disseminate ibuprofen particles in the solvents and do not allow them to settle at the bottom. They are also incorporated in formulation to increase the viscosity of suspension. Examples are xanthan gum or methylcellulose.

Solvents

Solvents

They are vital ingredients in an ibuprofen suspension and mainly act as the liquid phase in which ibuprofen powders and other components are dispersed. Water is the primary solvent and the main medium for dissolving medium. It is considered a non-toxic base for suspension preparation.

In other cases, small amounts of co-solvents, for instance, glycerin or propylene glycol are added to boost physical characteristics, such as texture, stability, and, dissolution of ingredients.

Sweeteners

Sweeteners

How does ibuprofen taste sweet? It is due to sweeteners. It offers a sugary taste to the ibuprofen suspension while concealing the bitter taste of ibuprofen. It increases the delectableness of suspension and increases children's compliance. Sucrose, sorbitol, and, xylitol are examples of sweeteners.

Preservatives

Preservatives

Ibuprofen suspension does not have a microbial presence. Why? Because of preservatives. They safeguard suspension from microbial invasion and extend its shelf-life. Methylparaben and propylparaben are included as preservatives.

Flavoring Agent

Flavoring Agent

You would surely have seen ibuprofen come in orange or strawberry flavor. How is that possible? Pharmaceutical developers usually include artificial or natural FDA-approved flavoring agents to enhance its sensory appeal and tastiness for young children.

Coloring Dyes

Coloring Dyes

Bright colors generally entice toddlers and children. Hence, ibuprofen suspensions are formulated in bright and vibrant colors, for example, pink or sunset yellow. Therefore, these hued suspensions not only attract young patients but also are pivotal in distinguishing different products.

Surfactants

Surfactants- Picture Courtesy: Biolin Scientific

You surely would have known surfactants by the name of surface-active agents. Why they are included in ibuprofen suspension? They serve an important function of facilitating the mixing of fat-soluble drug particles in the aqueous phase by coating them. This improves their interactions with liquid medium. They include polysorbate 80 (tween 80), sodium lauryl sulfate (SLS), and others.

Stabilizers

Stabilizers- Picture Courtesy: Study

As the name suggests, they stabilize suspension by averting the chances of particle clumping and settling during storage.

Buffers

Buffers- Picture Courtesy: Solution Pharmacy

Buffers are well-regarded for their adeptness in maintaining the pH of ibuprofen suspension. They are essential in averting pH-associated damage to ingredients and crystallization of ibuprofen. Critic acid and sodium citrate are used as buffering agents.

3.Why ibuprofen suspension manufacturing is popular among manufacturers?

You're right! Ibuprofen suspension manufacturing holds unlimited potential. It's a game-changer for both patients and the pharmaceutical industry. If you are keen on finding out its vital benefits, then take a look at the following points:

Simple Consumption for Sensitive Individuals

Simple Consumption for Sensitive Individuals

Pediatric and geriatric patients always opt for liquid ibuprofen suspension. Because it is fairly easy to take. Whereas, large capsules or tablets are difficult to ingest. This liquid formulation is designed to keep in mind the comfort of the patient. You can effortlessly adjust the dose adjustment with a spoon or a dropper.

More Medication for Relief

More Medication for Relief- Picture Courtesy: AdvaCare Pharma

Are you aware ibuprofen suspension provides quicker treatment relief? You would want to know why. During ibuprofen suspension manufacturing, tiny ibuprofen particles are readily dispersed in a liquid medium. Which rapidly solubilizes in the stomach's acidic environment; hence, more medication is available for absorption and therapeutic relief.

Appealing Flavors

Appealing Flavors- Picture Courtesy: ProPharma Group

Did you ever swallow bitter-tasting ibuprofen? Certainly not! Because ibuprofen suspension manufacturing involves the addition of sweeteners and fruity flavoring agents; so, the medication has an enjoyable taste. This appealing flavor makes the suspension more likable to young children.

High Expiration Duration

High Expiration Duration

Do you know that you can use ibuprofen suspensions for 1-2 years? This remedy has a prolonged shelf life because it is comprised of various preservatives and stabilizing agents. They minimize particle precipitation, pH alteration, and acidity changes that may result in loss of structural integrity of ibuprofen.

Budget-Friendly Processing

Budget-Friendly Processing- Picture Courtesy: Silverson

It is the biggest advantage for pharmaceutical manufacturers and it assists them in attaining financial stability. You do not need to buy expensive excipient ingredients, advanced equipment, and tools for ibuprofen suspension manufacturing. This decreases the manufacturing cost and optimizes resource utility.

4.Enumerate the key operational steps in ibuprofen suspension manufacturing.

Pharmaceutical manufacturers are normally interested in learning about key operational steps in ibuprofen suspension manufacturing to successfully formulate their superior-quality products. Let's shift our focus from benefits and learn about discrete operational steps in ibuprofen suspension manufacturing:

Preparing the Building Blocks: Raw Materials and Aqueous Base

Preparing the Building Blocks: Raw Materials and Aqueous Base - Picture Courtesy: Engineers Ireland

At the initial stage, operators are required to meticulously weigh the amount of ibuprofen as well as other additional excipients for example, sweeteners, preservatives, etc. Keep in mind to inspect the quality of your raw materials by visually examining them and conducting sterility studies.

After weighing the ingredients, the next step is adding purified water to the mixing container. After that, water-soluble ingredients, for instance, excipients and buffering agents are mixed in water. You are required to adjust the pH (4 to 7) of the mixture for ibuprofen stability.

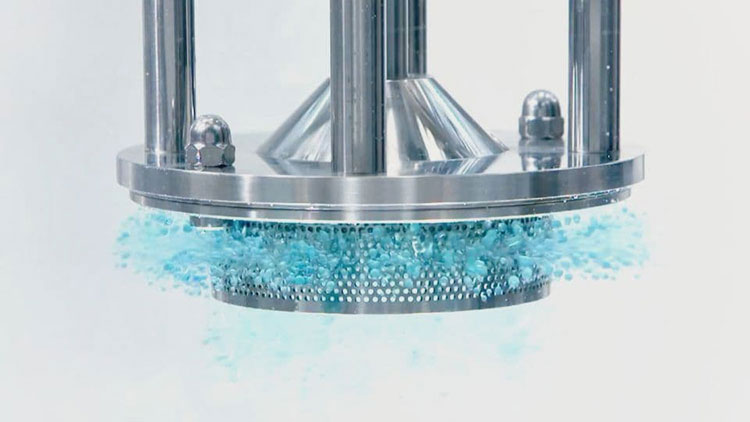

Creating the Ibuprofen Slurry Base

Ibuprofen Slurry Formation- Picture Courtesy: Silverson Machines

This step involves mixing ibuprofen with a small quantity of liquid and surfactant. This is carried out to form a consistent and smooth slurry. After that, the slurry is processed by different milling machines to minimize the size distribution of particles in the slurry and obtain homogenous dispersion.

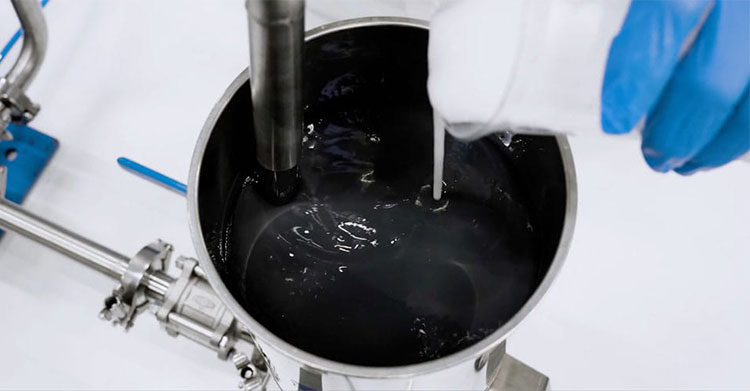

Suspension Formulation and Homogenization

Suspension Formulation and Homogenization- Picture Courtesy: Silverson

This is the primary step in the ibuprofen suspension manufacturing and at this stage, the ibuprofen slurry mixture is slowly added in the aqueous phase (prepared by water and excipients). This mixture is consistently stirred to prevent lump formation. Suspending agents are also incorporated in ibuprofen suspension to avert particle sedimentation.

Afterward, a high-speed mixer or homogenizer is employed to formulate a consistent and smooth suspension. Air bubbles- trapped in suspension- are also de-aerated at this stage. Finally, after homogenization, flavoring agents are incorporated into the slurry to impart the desired flavor.

Filtration and Quality Assessment

Filtration and Quality Assessment- Picture Courtesy: Scott Process

Now it's time for the filtration step, which is performed using advanced filters. In this step, various types of particulate contaminants and other impurities are cleared out from the suspension. Then, samples from batches are withdrawn to analyze particle distribution, viscosity, pH, and more.

Filling and Packaging

Filling and Packaging

At last, the ibuprofen suspension is ready for filling and packaging. The suspension is dispensed into the sterilized containers typically bottles with the help of filling machines. Subsequently, the filled bottles are sealed with automated capping units. Then, labels are glued on the bottles for communication purposes.

5.What machinery is essential in ibuprofen suspension manufacturing?

You might be wondering about the kinds of machines, needed to prepare ibuprofen suspension. Well, here is an answer for you. We are detailing a list of machines essential in ibuprofen suspension manufacturing.

Water Treatment System

AIPAK Engineering Purified Water Treatment System

First and foremost, the water treatment system is a must in ibuprofen suspension manufacturing because potable water is full of harmful toxins and contaminants that can jeopardize the health of consumers. A water treatment system is essential in purifying the water and generating pharmaceutical-grade water for use in ibuprofen suspension preparation as solvent.

There are different systems for water purification, such as reverse osmosis systems, deionization units, and ultra-filtration systems that remove dissolved impurities, ionic particles, and microbes, respectively.

Mixing and Blending Instruments

AIPAK High Shear Mixer

For properly homogenizing solid or liquid raw materials, mixing and blending equipment are utilized in ibuprofen suspension manufacturing. It mechanically processes substances and disperses, lifts, folds, and mixes them with diffusive or convective mixing. The material particles are mixed by the tumbling or shearing action of the mixing vessel.

Milling Devices

Allpack Colloid Mill

In this device, size reduction of ibuprofen particles or agglomerates is carried out by using various approaches of dicing, pulverizing, and grinding particles. Typically, by using physical forces, like attrition, shear, or impact, larger particles are crushed into smaller pieces. Different kinds of impact tools like blades, hammers, rollers, rotor-stators, or grinding mediums are used for the size reduction of particles. Milling instruments are vital in emulsification and slurry formulation.

Deaeration Systems

Allpack Vacuum Degassing Machine

Sometimes, de-aerated devices, for example, vacuum deaerators are employed in ibuprofen suspension manufacturing to remove dissolved air from preparation. Normally, a vacuum is created to suck air bubbles from suspension.

Filtration Systems

Filtration Systems

These instruments have an integral role in the separation and filtration of solid particles from the liquid suspension medium. Fine mesh filters and membrane filters are generally used for filtering larger insoluble substances as well as tiny minute microscopic contaminants like microbes from the suspension. Usually, filtering mesh or membrane retains solid impurities while liquid and ultra-fine materials pass through the apertures of the filtering device.

Filling and Capping Machines

Allpack Filling Machine

After the manufacturing of ibuprofen suspension, a liquid-filling machine is required to load the suspension into bottles. This system has automated filling units through which precise quantities of product are filled into bottles. Capping and sealing machines are also utilized in ibuprofen suspension manufacturing to place caps on bottles and seal them to retain product quality.

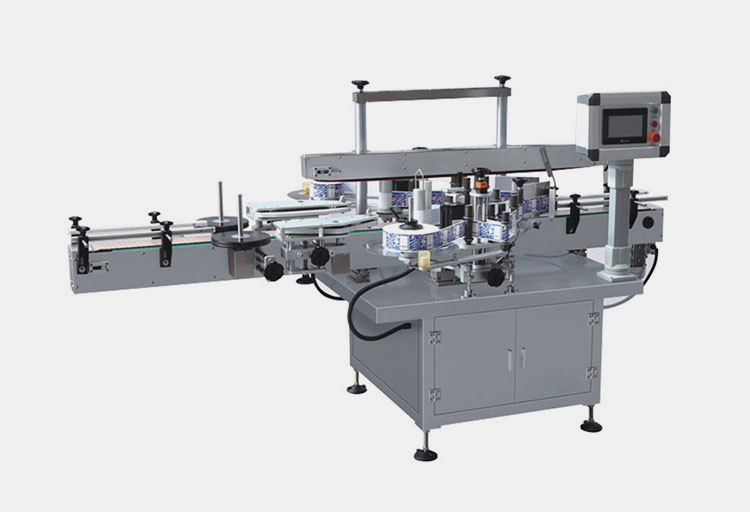

Labeling Machine

AIPAK Labeling Machine

Labels detailing critical product facts, for example, product name, ingredient list, dosage guidelines, expiry dates, and more are placed on suspension bottles by labeling machines. Diverse types of labeling machines are present to label the whole circumference of bottles, their front or back sides, and top corners.

6.What are critical problems related to ibuprofen suspension manufacturing?

If are you a part of ibuprofen suspension manufacturing, then you would have faced some critical problems. They certainly hamper manufacturing quality, safety, and regulatory compliance. These challenges arise from the intricate interaction of preparation, processing, and packaging factors.

Some of the significant critical challenges along with their mitigation strategies are penned below:

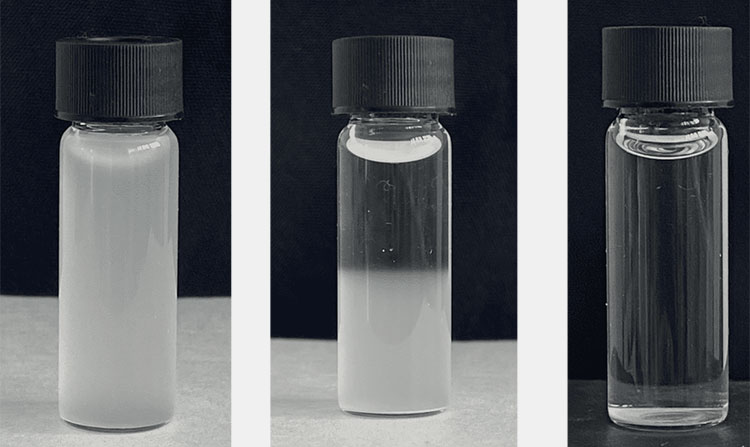

Crystallization and Sedimentation of Particles

Crystallization and Sedimentation of Particles- Picture Courtesy: Rheolution

It is a quite serious problem associated with ibuprofen suspension manufacturing. You will see that ibuprofen particles may deposit at the bottom of the container with time, resulting in uneven dosing. Or they may clump or agglomerate together due to alterations in temperature or pH. It has also been observed that ibuprofen molecules are broken down into inactive or toxic byproducts when exposed to certain conditions.

Solution

There are some strict control measures to resolve this issue, for example, by using effective suspending agents, sedimentation is prevented. Secondly, it is advised to narrow down the size range of particles to avoid crystallization or clumping. You can strictly regulate pH and temperature fluctuations during processing and storage to stop product degradation.

Poor Ibuprofen Availability

Poor Ibuprofen Availability

You will surely have problems with lower solubility and less than desired absorption of ibuprofen on your hands if you do not lower the size range of ibuprofen particles to a certain limit.

Solution

This problem has an easy fix. It is mitigated by the latest size reduction approaches, for instance, wet milling or high-shear mixing.

Irregularities in Suspension Viscosity

Irregularities in Suspension Viscosity- Picture Courtesy: Green Matter

It is absolutely established that variabilities in the viscosities of suspension will have a major effect on the measuring of dosage amount, leading to over- or under-dosing. Moreover, viscosity alterations also have a role in particle settling or hard clumping. Forgoing the addition of suspending agents or poor mixing could be the cause of this problem.

Solution

You can address this challenge by including the suspending agents in the preparation and properly mixing and homogenization materials with each other. Moreover, it is suggested to regularly conduct viscosity assessments throughout processing to ensure the desired quality.

Drug-excipient Compatibility

Drug-excipient Compatibility

Sometimes, you'll notice that ibuprofen and excipients are incompatible with one another and interact together, causing the breakdown of ingredients, undesired potency, or alteration in the color or flavor of suspension.

Solution

It is crucial to carry out compatibility and interaction studies between ibuprofen and excipients to assess and identify likely incompatibilities. It will allow you to choose excipients that are chemically stable and do not interact with ibuprofen.

Packaging Issue

Packaging Issue- Picture Courtesy: GEPACK

Did you encounter bottle leakage? Poor quality and unsound packaging materials are indeed the cause of this problem. It will result in product contamination, and permeability to light, air, and moisture.

Solution

Packaging challenges are easily mitigated by using excellent-quality, sturdy, tamper-resistant, and light-blocking materials. It is pivotal to carry out leakage and stability testing on packaging containers before their distribution.

7.What quality control tests are performed to validate the safety and efficacy of products in ibuprofen suspension manufacturing?

Quality Control Tests- Picture Courtesy: Compliancequest

In order to produce safe and effective ibuprofen suspension, you must properly implement quality control testing both in between and after product production. This testing is integral in verifying that ibuprofen suspension satisfies all the essential regulatory guidelines. So, let's have an overview of various quality control tests:

| Tests | Description |

| Testing of Active Pharmaceutical Ingredients

|

It is an important examination, conducted to assess the amount of ibuprofen in the suspension. Normally, high-performance liquid chromatography (HPLC) is performed to gauge the exact concentration of ibuprofen. Afterward, the results are compared with pharmacopeial standards to check if the concentration of the therapeutic compound is within the range or not. |

| Viscosity Analysis

|

In this testing method, the fluidity or flow characteristics of ibuprofen suspension are determined. This quality control test is integral for product dosing accuracy and patient acceptance. You can use a Brookfield viscometer to estimate viscosity under various regulated conditions. |

| Dissolution Testing | This appraisal is conducted to evaluate the timing and amount of ibuprofen released from suspension in an instrument that mimics the environment in the gastrointestinal tract. Dissolution apparatus is utilized for this testing. |

| Sedimentation Rate Testing | This test has major significance in ibuprofen suspension manufacturing. It determines the ability of particles to tolerate the settling during storage. It also checks the re-dispersibility rate. In this analysis, suspension is allowed to settle and then its sedimentation volume is measured. Also, redispersion is analyzed with manual shaking or employing automated instruments. |

| Microbial Limit Assessment | In manufacturing, this test is executed to validate that ibuprofen suspension is free of dangerous pathogens. Total aerobic microbial count and total yeast and mold count identify aerobic bacteria and fungal contamination, respectively. Also, tests are performed to investigate E. coli, salmonella, Staphylococcus aureus, and Pseudomonas aeruginosa contamination in suspension. |

| Heavy Metal Testing | In this analysis, suspensions are checked to investigate the presence of harmful heavy metals, such as lead, arsenic, or mercury. Typically, inductively coupled plasma mass spectrometry (ICP-MS) is used for heavy metal testing. |

8.What advancements in technology are shaping the future of ibuprofen suspension manufacturing?

In today, technological-driven world, wherever you turn, you will see technological revolution has left its mark. Similarly, ibuprofen suspension manufacturing has also benefited from technological advancements. Let's discuss how technology has shaped the world of ibuprofen suspension manufacturing:

Continuous Production System

Continuous Production System- Picture Courtesy: SOMAÍ Pharmaceuticals

Nowadays, more and more pharmaceutical businesses are opting for continuous manufacturing to develop ibuprofen suspension. Traditional batch processing is comprised of numerous distinct steps, which could cause production inefficiencies and risk of manufacturing errors and contamination.

But with continuous manufacturing having a single integrated system, you can get all-in-one production from raw feed to end product.

Latest Particle Size Reduction Techniques

Nano-milling- Picture Courtesy: Hockmeyer

Nano-milling and high-pressure homogenization are the latest milling techniques that generate ultra-fine particles to boost ibuprofen solubility and dispersal in the liquid phase. This in turn translates to better absorption and bioavailability.

Process Analytical Technology (PAT)

Process Analytical Technology (PAT)- Picture Courtesy: Bruker

PAT is introduced to allow real-time monitoring during manufacturing by examining the concentration of active ingredients and excipients during mixing and ensuring their even solubilization in suspension. You can also effectively control discrete parameters, such as pH, viscosity, temperature, and more through PAT.

Automation and Robotics

Automation and Robotics- Picture Courtesy: Contract Pharma

In this era of artificial intelligence, automation, and robotics have become a new norm of success. Integration of robotics in ibuprofen suspension manufacturing enables you to automatically weigh, mix, fill, and label final products for both accuracy and speediness. This has the advantage of reduced human involvement and lowering contamination and error rates.

Conclusion

Ibuprofen suspension represents more than simple relief- it is a testament to the elaborate science and unyielding innovation propelling modern pharmaceutical processing. The manufacturing of this trusted pain ally involves careful selection of excipients, mastering particle size reduction, fine-tuning mixing, exact dose filling, and secure sealing. With sophisticated pharmaceutical equipment such as mixers, millers, and fillers, you can take your ibuprofen suspension manufacturing business to new heights. And this is only possible with the help of experts like AIPAK ENGINEERING. We have an extensive catalog of machines related to ibuprofen suspension manufacturing, so make sure to reach us if you want to find the right machine for your production line.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours