Syrup Filling Machine: The Complete FAQ Guide In 2025

Change in weather always brings cough and sore throat. But do you know what is the remedy for these illnesses? You have guessed it right! It is syrup. It is full of ingredients- both natural and synthetic- that ease your respiratory problems.

Have you ever contemplated about filling processes of syrup? What machines are used for packing these products? A superior addition called the syrup filling machine, seamlessly brings out filling processes with perfection. It advances the production lines with its diligence and cost-effectivity.

However, before procuring this machine, first, take a step back and read this enlightening FAQ guide about a syrup filling machine. This blog post is full of useful facts that’ll assist you in operating your machine in the right way. Let's go full steam ahead.

1.What do you know about the syrup filling machine?

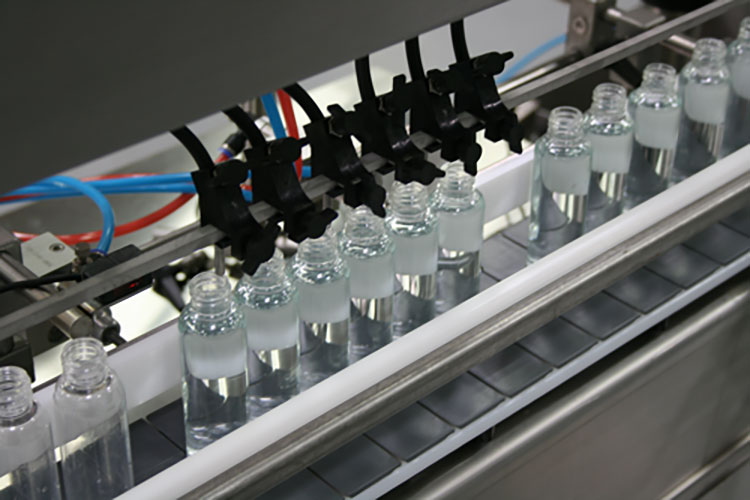

AIPAK Engineering Syrup Filling Production Line

A multitude of syrups- varying in fluidity and texture can be spotted on the market aisles in diverse kinds of packaging. What equipment is used for filling syrups? This equipment is called a syrup filling machine that also goes by the name syrup filler in other industrial sectors. It is a specialized piece of equipment best for manufacturers, who are dealing in thinner or thicker consistency solutions and suspensions.

This machine is designed to aid you in filling and sealing a diverse range of liquids- whether free-flowing or non-free-flowing in a broad range of containers. It provides you with syrupy products in packed containers with a perfect amount of accuracy and hygiene.

2.How does a syrup filling machine aid production?

A syrup filling machine has precision filling for every single drop. It guarantees you fast and consistent filling every time and everywhere. With this machine, you’ll have absolutely no discrepancy in product loading because it is customized for your processing needs. It has a vast list of advantages through which it aids production. So, we are detailing some of these benefits for your learning.

Built for Speed and Efficiency

Built for Speed and Efficiency- Picture Courtesy: AND & OR

This machine comes in handy when every manual filling method fails. The fast-paced world demands medications- such as syrups- at swift rates. Thus, developers have fabricated this device to accomplish high-speed filling and improved throughput rates.

Its core is fabricated with automated technology and advanced control and processing centers. With which you can fill hundreds of thousands of containers per batch. Hence, there is no chance of late delivery using this machine.

Cost-Efficiency is Goal

Cost-Efficiency is Goal

Financial success and profit margins are always occupying the thoughts of brands and producers. They ensure that their syrup filling machine is worth the investment. It certainly is. It takes the profit graph upward and lowers the wastage of products at the same time. Furthermore, you do not need a huge labor force after procuring this machine. This reduces your labor wages. While boosting the cost-effectivity of this machine.

Ultimate Precision

Ultimate Precision- Picture Courtesy: ADM

It is a game-changer for your business. Why? This is because of fact that a syrup filling machine is a one-stop solution with sophisticated filling systems and sensors, by means of which you can check and verify the volume of every single drop of syrup. It is the finest example of accurate filling reliability in every container.

Rapid Changeovers

Rapid Changeovers- Picture Courtesy: Accutek Packaging Equipment

This device is furnished with innovative and high-tech control screens and processing units. With which you could speedily fine-tune and amend its fill checks. And you’re able to continue with your filling cycles without even the tiniest bit of downtime. Diverse container types are packaged through a syrup filling machine, thereby, diversifying your product portfolio.

Model for Cleanliness and Hygiene

Model for Cleanliness and Hygiene- Picture Courtesy: Reliance Machinery

Manufacturers habitually fret over the possibility of product contamination. Because it casts a cloud over their selling chances. Product contamination never happens with the syrup filling machine. Now you’re surely questioning what measure this machine takes to certify product sterility.

Well, first of all, it is manufactured using high-quality and hygienic materials that do not release any contaminants in the syrups. Secondly, it is very easy to take apart and fully clean this machine. Further lessening the risk of product buildup, which could deteriorate product quality.

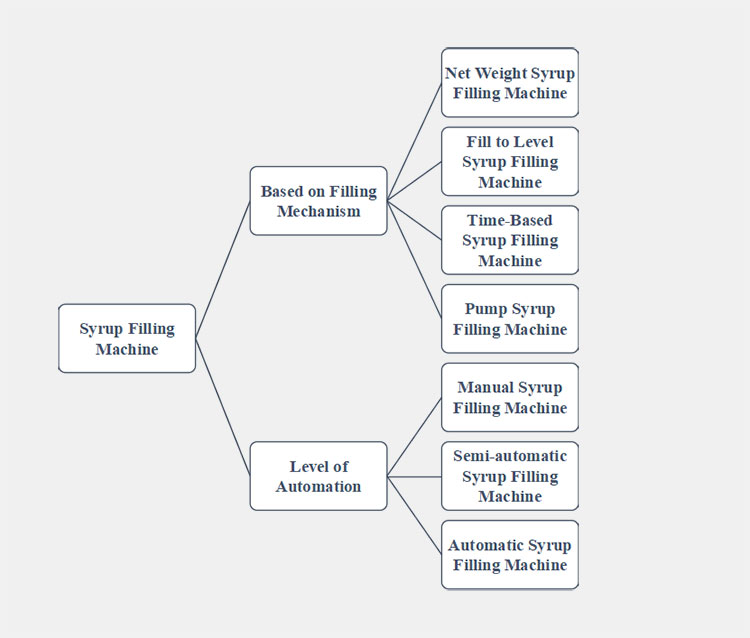

3.Are there types of a syrup filling machine?

Yes, the syrup filling machine is categorized into multitudes of types, depending upon the filling mechanism and level of automation. Let’s discuss the major types of a syrup filling machine:

Based on the Filling Mechanism

Net Weight Syrup Filling Machine

Net Weight Syrup Filling Machine- Picture Courtesy: Federal Mfg

This type of syrup filling machine is quite distinct from other categories of syrup filling machines. As it loads syrups by their weight instead of filling them by volume. Definitely! It offers superior control over accuracy. It is desired in various facilities because it does not allow even a little variability in dosing.

Therefore, you can achieve quality control as well as regulatory compliance using such a device. In addition to this, you can conveniently pack all types of syrups, whether they have dilute consistency or have concentrated and viscous runniness.

You easily cut down your expenses using this device because it prevents overfilling. Which is ideal for loading high-end syrups.

Fill to Level Syrup Filling Machine

Fill to Level Syrup Filling Machine- Picture Courtesy: ACASI Machinery

This equipment is better known as an overflow syrup filling machine. It is dissimilar from other syrup filling machines for the reason that its working principle is based on level-based filling. This means that instead of relying on filling accuracy, it loads every container in the batch to the same level. Indeed, this is useful for improving the visual appeal of the products. Moreover, brands use this machine to create every bottle with a uniform appearance.

You can use this equipment for loading clear or semi-clear containers. Besides, this instrument is preferred for dispensing thinner to medium viscous syrups. It also works best for foamy syrups. Because they could be fluidized back to the filling tank once loading is completed. Hence, you can save precious and costly syrups.

Time-Based Syrup Filling Machine

Time-Based Syrup Filling Machine

This machine has one of the simplest filling mechanisms. It basically uses a time limit for loading various quantities of syrups. In contrast to other kinds of syrup filling machines that dispense precise volumes or weights of the syrup, the filling in a time-based syrup filling machine is determined by time-based fillers.

Users just have to adjust their preferred time and the machine will dose the syrup for that particular duration of time. You can employ this machine when dealing with thinner or watery syrups. Furthermore, it is typically used when precision is not the first choice.

One of the most beneficial pros of a time-based syrup filling machine is that it comes with a lower price tag. You can easily maintain and clean this instrument because of its smaller number of parts.

Pump Syrup Filling Machine

Pump Syrup Filling Machine- Picture Courtesy: N.K Industries

You’ll find this type of pump syrup filling machine in every industrial unit. The reason is because it is a highly flexible unit having various kinds of pumps-such as piston, peristaltic, gear, or, diaphragm pumps. Therefore, you can use this machine to fill every liquid under the sun. These fluids could have any type of consistency and fluidity, from watery to highly viscous. Not only this, a pump syrup filling machine is also utilized for loading foamy or bubbly liquids.

You can conveniently utilize this machine owing to its extreme filling precision. Undeniably, it loads exact quantities of syrups. Ultimately resulting in fill uniformity in every filling vessel.

Based on the Level of Automation

Manual Syrup Filling Machine

Manual Syrup Filling Machine- Picture Courtesy: Rhino-Pak

It is a compact-sized filling device, specifically built for small-sized facilities and home-based pharmacies. Even though it is on the smaller end of the spectrum, still it packs huge sets of advantages- for instance, simple operativity and budget-friendliness. It has the simplest type of control. So, you can operate this machine without extensive training.

You could move this device anywhere owing to its lightweight property and smaller footprint. However, it requires excessive labor supervision. Because loading to unloading is completely manual. Therefore, it needs huge effort on the operator's part.

Semi-automatic Syrup Filling Machine

Semi-automatic Syrup Filling Machine- Picture Courtesy: Bhalani Group

This kind of syrup filling machine is usually found in mid-level filling production. Do you know why? Because it has a dual mode of operativity- both automation and manual. It has partial automation, due to which it needs users for its working- for example, depositing containers and syrups in the filling machine and offloading the packed product from the instrument.

It requires the presence of workers to start and monitor its filling process. But you can automatically load syrups in containers with its customized and high-tech control systems. This instrument has modifiable settings to adjust filling rates according to requirements. Consequently, it results in lesser product wastage and regulation in volume control.

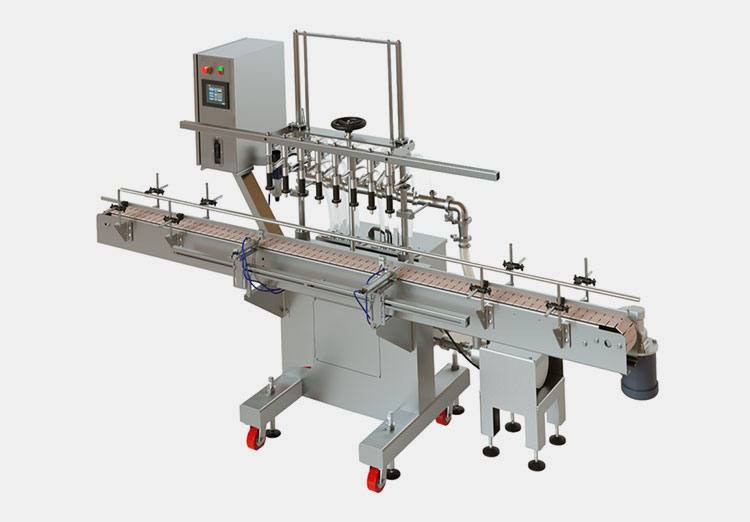

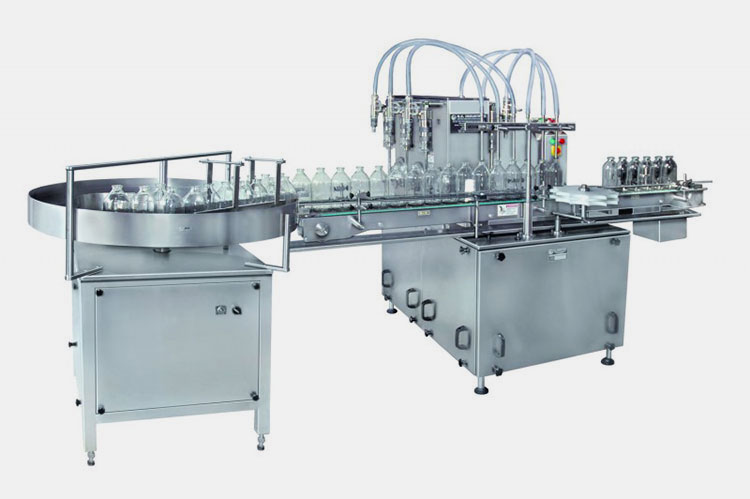

Automatic Syrup Filling Machine

Automatic Syrup Filling Machine

It is the latest model of syrup filling machine because of its advanced automation. It is the preferred choice for mass-scale production. Why is that? Because it is completely mechanized and integrated with automatic loading and discharging systems. So, it needs little to no operator supervision.

It is a large-sized machine, optimized to process bulk batch loads, leading to higher throughput. You can use this device for different types of syrups and containers due to its configurable settings. It is favored in large settings. Owing to its optimal efficiency, every cycle.

4.What are the market applications of a syrup filling machine?

A syrup filling machine is a notable component of every global industry. Since it is perfect for bottling concentrates, syrups, and every sundry liquid. It is a must-have for an efficient syrup filling line setup. And it has unmatched precision and top-tier yield.

Let’s explain various industrial applications of a syrup filling machine in-depth:

Pharmaceutical Industry

Pharmaceutical Syrup- Picture Courtesy: Behance

A syrup filling machine is the backbone of the pharmaceutical industry. Because every medication drop counts, therefore, pharmaceutical brands always fill their cough syrup, dental mouth washers, painkillers for children, liquid antibiotics, and gastric formulations utilizing this device. It is an engineering marvel, quite marvelous in its precise dosing. That absolutely promises the dose accuracy for patients.

Nutraceutical Industry

Nutraceutical Syrups- Picture Courtesy: Nutzabouthealth

Are you tired of ingesting nutraceutical pills and capsules? Nowadays, you can switch to liquid vitamins and minerals. They are available in a diverse range of bottles that are loaded by a syrup filling machine. Sure, this device carved its niche in the nutraceutical industry as well. It is well-regarded owing to its smooth operativity and clean configuration. Ensuring error-free and sterile filling time and again.

Food Industry

Food Syrups- Picture Courtesy: Behance

The food industry deals with every type of liquid product having diverse viscosity profiles. A syrup filling machine is FDA and GMP-compliant. So, every food brand producing liquid consumables favors this system over manual filling because of its hygienic assembly and no drip and spill instances. It dispenses caramel, liquid sweeteners and flavors, chocolate spread, honey, mustard, dressing, concentrated juice, coffee syrups, maple syrups, and much more.

Cosmetic and Personal Care Industry

Cosmetics and Personal Care Products- Picture Courtesy: Behance

Syrup filling machine is an absolute necessity of the cosmetic and personal care industry. Why it has a special place in the cosmetic industry. Because it is fabricated with specialized filling parts that gently handle delicate and sensitive cosmetic products. Without damaging their composition, visual appeal, aroma, texture, and, functionality. It is reliable every single time. Hence, it introduces lotions, gels, serums, essential oils, body washes, sanitizers, and liquid makeup.

Agriculture Industry

Fertilizer- Picture Courtesy: Behance

At first glance, it may seem confusing to you. However, a syrup filling machine has craved its way into the agriculture industry. As it is made with chemical and corrosion-resistant parts, thus can handle harsh agriculture chemicals. Exact dosing of concentrated products is its principal pro in the agriculture industry.

Dairy and Specialty Foods

Dairy Products- Picture Courtesy: Behance

Various dairy products like milk, cream, butter, and cheese as well as specialty items, for instance, dessert sauce, flavored syrups, and others are available in glass and plastic bottles. Therefore, you will see a syrup filling machine routinely in the dairy and specialty food industry. Is this machine safe for processing dairy? Certainly! It hygienically doses dairy products with no likelihood of contamination with its closed and sanitary construction.

5.How does a syrup filling machine work?

From filling to capping- it performs every step with automated efficiency. It involves a series of coordinated stages to ensure streamlined efficiency at work. A complete list of various steps occurring in the operation of a syrup filling machine is penned below to enlighten your minds:

Setting up Machine

Setting up A Syrup Filling Machine- Picture Courtesy: Robbe Industries

At first, you’ve to deposit bulk volumes of syrups inside the large tank and hopper, particularly designed to enclose the product. In some cases, these hoppers have temperature controls to accomplish uniformity in the flow of thicker syrups.

Now you’ve to input programming parameters on the touch screen or toggle screen of a syrup filling machine. What do these parameters include? These parameters include fill volume, fill speed, and nozzle height.

Positioning of Containers Under Nozzles

Positioning of Containers Under Nozzles- Picture Courtesy: IVEN-Pharma

This step is carried out with manual labor in manual or semi-automatic machines. The job of the operator is to place the container under the nozzle. On the other hand, containers are loaded in the unscrambling machines and then they automatically travel along the conveyor towards the filling nozzles.

Filling

Syrup Filling- Picture Courtesy: IVEN-Pharma

You’re likely thinking about the filling mechanism of a syrup filling machine. Well, here is a detail of the filling step for you. In manual types, the operator is in charge of initiating the filling process using a lever or button. While, in automatic types, the sensors equipped in these machines identify the presence of a container under the filling nozzles, which commences the filling procedures. How filling step actually happen?

Different mechanisms and components- for example- gravity, piston, or pump- play an integral part in filling. These systems exert pressure force to draw fluids from the hopper and then liquids are pushed to filling nozzles.

Filling Completion

Filling Completion

The loading of syrups automatically stops, as soon as input volume or weight is attained. Some versions of filling nozzles have anti-drip characteristics. What for? They fundamentally to avert chances of leakage after every cycle.

Container Discharge

Container Discharge- Picture Courtesy: Pack Leader

It is the last step in the working of a syrup filling machine. In automatic models, the filled containers are transported to other machines for post-filling protocols using conveyor systems after the conclusion of filling.

6.What are other instruments installed with a syrup filling machine?

A syrup filling line does not only have a syrup filling machine but also has other devices as well, for seamless packaging. These sets of machines are pivotal in helping you attain hygiene and meticulousness. Let’s have a look at the order of machines found in a syrup filling line:

Unscrambler

AIPAK Unscrambler

This device is the first-in-line machine that carries out the useful function of placing containers on the conveyor of a syrup filling machine. What is its structure? It has a rotary table and container hopper in which bulk quantities of containers are placed initially. First, containers are randomly tossed into huge hoppers. Unscrambler usually receives containers in random and disoriented patterns. And it executes the task of putting upright containers at fixed gaps.

Accurately performs its function. Without it, your filling line does not work correctly and will ultimately break down.

Industrial Washer

AIPAK Industrial Washer

Did you ever see an impurity in a syrup bottle? Certainly not! This is because there are several sterile systems, one of them being the industrial washer. It has decisive significance in the industries. How come?

It is well-accepted in the industrial sector, as it completely separates and clears out contaminants and foreign objects from both the inside and outside of containers. It has heavy-duty water spray systems, air jets, and, ultrasonic radiations.

Tunnel Sterilization Oven

AIPAK Engineering Tunnel Sterilization Oven

It is imperative that you sterilize and remove microorganisms from every container in the batch. But how it is done? A highly dedicated unit called a tunnel sterilization oven is ideal for performing this feat. This machine uses high temperatures and hot air to completely eliminate harmful pyrogens and other microbes from containers.

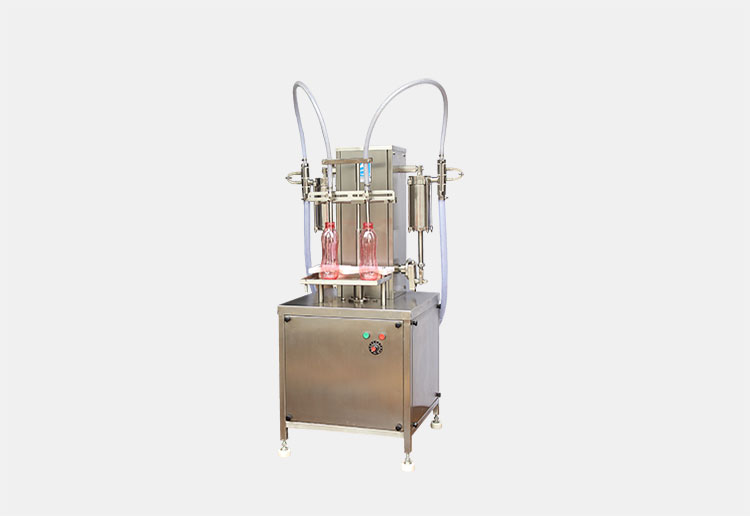

Liquid Filling Machine

Liquid Filling Machine- Picture Courtesy: Pacific Inline Filling

It is a central machine on which the whole syrup filling line is based. It is furnished with top-notch filling pumps, controls, and nozzles that guarantee perfect syrup loading on every occasion. Filling nozzles are the main components of this instrument that actually come in contact with containers and precisely deposit varying liquids in syrups.

Liquid Capping Machine

AIPAK Liquid Capping Machine

Surely, you’ve observed vials and bottles with caps on the market shelf and you may find yourself guessing what machine is associated with the capping process. Liquid capping machine- a superior device- is favored in syrup filling lines since it sorts and fixes different kinds of caps on the syrup containers.

With this machine, you’re able to preserve the quality, purity, and potency of your product. The liquid capping machine tightly closes the openings of the container to prevent any possibility of leakage and contamination.

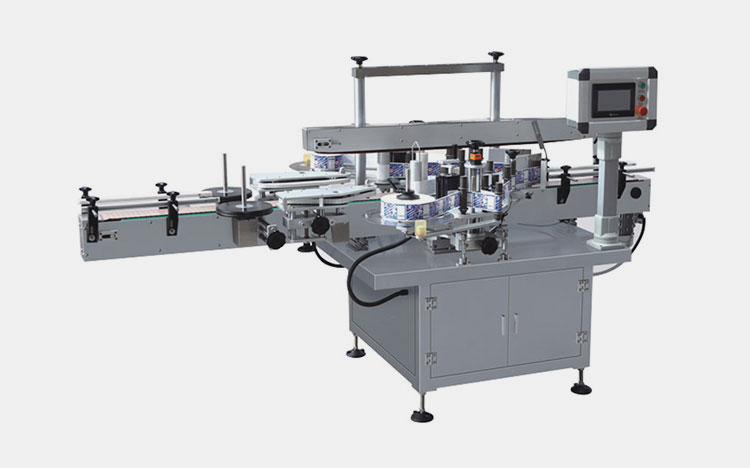

Liquid Labeling Machine

AIPAK Liquid Labeling Machine

Liquid labeling machine uses labeling heads, rolls, unwinders, and, label press devices. What is its advantage? This device has a spotlight due to its significance in product branding and communication. Because it attaches and glues a diverse range of striking and informational labels at different positions of containers.

7.Can syrup filling machines process various viscosities of syrups?

Viscosities of Syrups- Picture Courtesy: Accutek Packaging Equipment

Manufacturers dealing in syrup having different viscosity profiles, often contemplate this question. However, the short answer is yes. A syrup filling machine is a renowned unit that effortlessly dispenses syrups that are thinner water-like as well as thicker honey-like s. It handles a full range of viscosities using its advanced features, including:

It is customized with a variable pressure pump with which you could alter the pump force to have uniformity in the fluidity of syrups with diverse runniness. This machine is supplied with various nozzles, differing in their dimensions and geometries. So, that you’d process both watery and viscous syrups.

A syrup filling machine has different speed ranges to dispense different viscosities. For example, low speed for thicker syrups and fast speed for thinner syrups. In addition to this, some models may also have heating elements to heat sticky syrups to increase their flow.

8.What types of containers can syrup filling machine load?

When you go out shopping, you’ll notice syrups in diverse types of containers. How can this happen? Well, by a syrup filling machine. It has adjustable program options, with which it can dispense assortments of container types, for example:

Bottles

Syrup Bottles

They are manufactured in different styles to catch the eyes of customers. There is a diversity in syrup bottles which are created in rectangular, oval, cylindrical, square, and intricate shapes. Glass bottles are clear and you can use them to store premium and high-value syrups.

Cans

Syrup Cans

Indeed! Different variations of syrups are packed in durable cans for long-term storage. Are there different types of cans? Absolutely! Although syrup cans are typically found in cylindrical or rectangular geometries. They are created from different metals- aluminum and tin plates.

Jars

Syrup Jars

They are a common type of container for enclosing syrups. A syrup filling machine easily handles jars because they have similar dimensions to that of bottles. You can use glass jars to contain viscous syrups, such as fruit preserves. While plastic jars are utilized for bulk packaging.

9.Is it effortless to clean and sterilize the syrup filling machine after batch processing?

Syrup Filling Machine- Picture Courtesy: In-Line Packaging Systems

Cleaning a syrup filling machine is an integral aspect of operating a machine. Without a doubt, it can aid you in improving the yield and processing of equipment. Hence, let’s have an insight into machine capacities through which you can clean and sanitize a syrup filling machine effortlessly:

| Clean-in-Place (CIP) Measures | Today, improved CIP systems are being introduced into the market. Using these systems you can conveniently improve automation in cleaning. CIP devices wash the syrup filling machine with cleaner, detergents, and, water. In this way, you’ll achieve faster and more efficient cleaning. |

| Quick-Release Components | Yes, you could significantly enhance your cleaning outcomes by buying a device that has quick-release components, for example, nozzles, hoses, pipes, seals, etc. They’re rapidly detached and separably washed and dried. |

| Hygienic Material | You’ll unquestionably cut down the possibility of accumulation of microbes and residues by using a machine manufactured from stainless steel and polished exterior. These materials are quite easy to clean. Syrup clogging could be minimized with the use of non-stick coating parts. |

| Automation in the Rinsing Cycle | Cleaning is also done thoroughly by utilizing customized rinsing cycles. This automatically sprays water or cleaning agents into the device and wash out syrup particles. |

10.What are ways to solve various technical issues in a syrup filling machine?

Are you running into minor or technical issues with your syrup filling machine? Do they are decreasing your work efficiency? If yes, then for your peace of mind, we are describing various technical issues and ways to rectify them.

Irregularity in Fill Amounts

Irregularity in Fill Amounts- Picture Courtesy: Apex Filling Systems

| Problem | Troubleshooting |

| It is certainly a huge issue that could break the reputation of a brand. Overfilling and underfilling are the result of various reasons, for instance, malfunctioning fill pumps, fluctuations in air pressure, and faulty instrument programming. | You can have proper filling levels by:

Assessing the appearance and working of filling pumps. And ensuring they are working smoothly and are not damaged in any way. Also, there should not be any air bubbles or leaks in the pumps. Maintaining the stability of the air pressure within the optimized range. Calibrating the equipment programming to ascertain homogeneity in fill amounts. |

Syrup Leakage from Nozzles

Syrup Leakage from Nozzles

| Problem | Troubleshooting |

| Have you seen syrup dripping from nozzles? It is a fairly frequent issue that occurs during operation. This results in the loss of high-priced syrups, causing severe monetary difficulties for businesses. It can be attributed to old or damaged seals on nozzles or also to erroneous settings for nozzles. | These instructions help you in solving syrup leakage or dripping issues:

You should systematically inspect every section of nozzle seals and immediately replace them if they look significantly worn out. Also, you should scrutinize the alignment of nozzles and their settings. And orient and tighten them to have a smooth loading cut-off. Think about installing anti-drip nozzles or cut-off valves if you’re still having dripping difficulties. |

Incorrect Positioning of Bottles

Incorrect Positioning of Bottles

| Problem | Troubleshooting |

| From time or time, you would’ve notified improper alignment of bottles on the conveyor. In fact, this perhaps reduces filling throughout and wastes expensive syrups. Definitely, the misalignment of guides and wrong settings of the positioning sensor contribute to this issue. | Some suggestions to correct this problem are:

First, it’s best to examine the alignment of guides and properly align them so that you can achieve proper orientations of containers. Likewise, give it a once-over at the positioning sensors to calibrate and clean them. |

Reduced Syrup Flow

Reduced Syrup Flow- Picture Courtesy: Tecnomaco

| Problem | Troubleshooting |

| Have you faced the problem of decreased fluidity of syrup from nozzles? If yes, then it could minimize filling speed. You may have a blockage or clogging in the pipeline that could be the cause of the above-mentioned problem. | To resolve this error, you should consider:

Checking the pipes for jams and cleaning them meticulously. Replacing portions of the pipeline that are drastically worn-out or have a tendency to regular jamming issues. Also, proactively flushing out hoses, nozzles, and pipes, prevent this issue from happening in the first place. |

Incorrect Speed Regulation

Incorrect Speed Regulation- Picture Courtesy: Tecnomaco

| Problem | Troubleshooting |

| If you’re experiencing inadequate speed regulation, it could decrease your filling rate and production flow. This issue is largely connected with defective or worn-out motors or glitches in the control panel. | The possible approaches to correct this problem are:

First, take a look at the motor component of the machine. You should replace it if it’s beyond repair. Secondly, errors in the control panel are effortlessly solved by recalibrating the control board of the equipment. After calibrating, you should ensure all the operational settings are correctly adjusted and the machine is working in the right way. |

Conclusion

A syrup filling machine is gaining recognition worldwide because of its pure efficiency and zero hassle. You simply have to set it and then watch it work. Owing to its absolute precision, it’s become a permanent fixture in every production type. Its wide range of advantages include financial stability, high throughput, and, thorough cleaning. You can cross every success block by integrating this machine into your business. Now after reading this guide, you’ll be able to choose the perfect machine. Without delay, get in touch with us now. Why us? Because, AIPAK Engineering offers you a vast portfolio of machines with high-quality parts, long-term warranties, and the finest customer support.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours