Injection Vial Filling Machine: The Complete FAQ Guide In 2025

Did you know that injection is considered the most effective way of instant drug delivery? Well, the answer may be yes or not! What here significant is to highlight the importance of injectable liquid medications. These aqueous solutions are better preserved in vials due to their enhanced safety, convenient usage, and precise body. However, accurate filling of these vials is a conundrum whose solution only lies in an Injection Vial Filling Machine!

This machine is made with standout features to fulfill all the basic and advanced requirements for injection vial filling. Not only this, but the machine also supports quick operation procedure, easy maintenance routine, and offers range of types to choose from. So, before causing any delay just take a start and give this FAQ Guide of an Injection Vial Filling Machine a good read!

1.What Is Injection Vials?

Injection vials with injection- Picture Courtesy: biopharminternational.com

Injection vial is a small size glass bottle which is used to store precise dose of liquid or powder medication. It consists of a glass body and a cap to provide a hygienic atmosphere for the content. Injection vials are particularly used for the preservation of antibiotics, injection water, vaccines and other injectable powders.

The size and structure of injection vials make its handling quite intricate that must be carried out responsibly. For this purpose, specialized machines are designed among which one of the core equipment is injection vial filling machine.

2.Define An Injection Vial Filling Machine?

Injection vial filling machine for powder- Picture Courtesy: romaco.com

Injection vial filling machine is a sophisticated machine tailored with innovative features to cope up with the complexities of injection vial filling. The machine is a construction of various components which together make up its structural body and energize it to carry out the filling of injectable liquid and powder suspension into vials.

Its stainless steel body with enclosed structure provide a safe environment for the handling of injection vials. Similarly, it works on automatic principles where it simply processes the injection vials through flexible mobilization and discharging of precise dosage. Hence, it is a comprehensive solution by functioning standalone and is also open to be integrated with other machines.

3.Enumerate The Advantages Of An Injection Vial Filling Machine?

An injection vial filling machine comes up with numerous attributes which can give you many advantages in terms of quality performance as well as efficacy. So, let's know few of them in detail!

Enhanced Production

Liquid filled injection vials- Picture Courtesy: fillmed.con

Every manufacturer dream for extending their production while minimizing time and energy spent. This aim is perfectly fulfilled by an injection vial filling machine which gives you extremely promising results in terms of production output. With automatic system and high efficiency the machine can fill up to 12,000 vials just in an hour.

Improved Safety

Hygienic operation of injection vial filling machine- Picture Courtesy: cozzoli.com

An injection vial fully displays a robust machine which is fully resistant to corrosion as well as bacteria. Thus, it can safely fill all kinds of liquids and powders whether soft or corrosive. Apart from this, the machine has multiple system for carrying out safe operation such as flexible plastic holders for handling the sterile vials, enclosed transparent window, and emergency stop for machine protection.

Filling Uniformity

Uniformly filled liquid injection vials- Picture Courtesy: adinath.co.in

Precision and dosage uniformity are considered substantial in the delivery of accurate medication and reducing risks of errors. In this way, an injection vial filling machine can perfectly weigh the precise volume of dosage and dispense it into the awaiting vial. Hence, each finished vial is a perfect display of uniformity.

High Flexibility

Various sizes of vials & caps- Picture Courtesy: environmentalexpress.com

An injection vial filling machine is extremely versatile and flexible with its automatic changeover of parts, dealing with various sizes of vials, and the capability to be scaled for meeting business needs.

Reduce Waste

No vial no filling principle- Picture Courtesy: tofflon.com

Another most significant advantage of an injection vial filling machine is its ability to reduce waste by employing different techniques. For instance, it follows the principles such as no vial no filling and no vial no stoppering. Ultimately, it reduces waste that can save your money.

4.What Is The Importance Of An Injection Vial Filling Machine In Pharmaceutical Industry?

Pharmaceutical industry display- Picture Courtesy: cozzoli.com

Pharmaceutical industry is a field where strict principles are followed from the raw ingredients processing till their final transformation into finished products and packaging. It is necessary for maintaining the quality control of range of medications because minor irresponsibly can cause great losses.

Since, injectable liquid and powder medications have been used for a long and still in practice especially after COVID-19, the importance of an injection vial filling machine cannot be denied. It provides aseptic way for hygienic packaging of the produced medications which is the most important step in pharmaceutical industry.

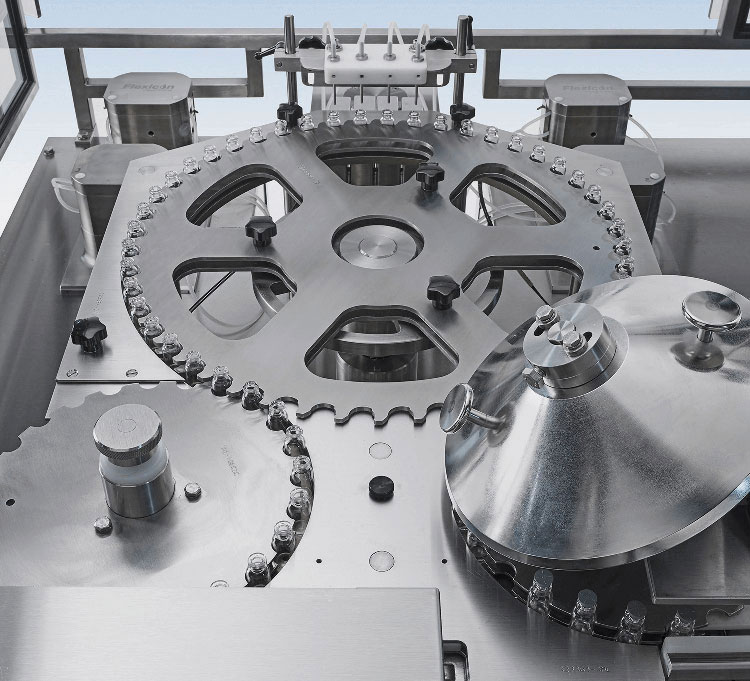

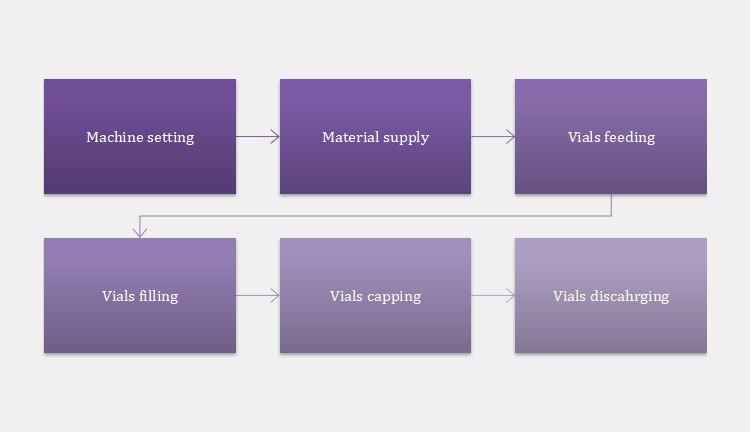

5.Explain The Working Principles Of An Injection Vial Filling Machine?

The working principles of an injection vial filling machine are pretty easy. You just need to understand how it starts and through what steps it goes on until the final discharge of filled vials. So, let's know these steps in detail which will surely help you in understanding both the process itself and how you can operate your machine in a well way!

Machine Setting

Whenever you are about to operate your injection vial filling machine, don't forget to first go for its setting which is quite simple. In this step, you just need to make sure your machine is in good working condition by checking its parts like they are located on right place. Similarly, you have to set the machine parameters through control panel which will include the fixation of amount to be filled in each vial and the speed of filling etc.

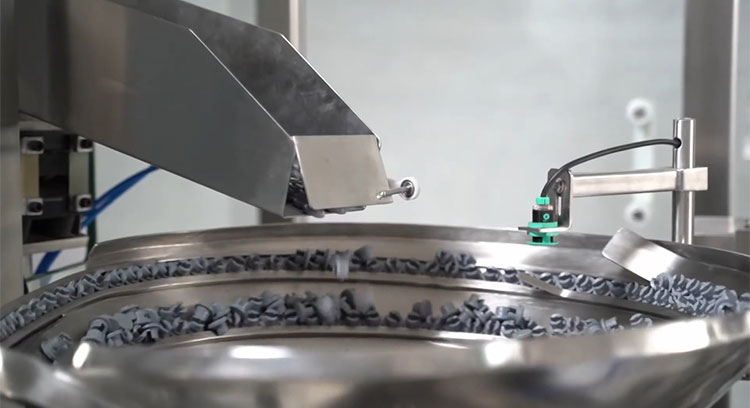

Material Supply

Vial caps hopper- Picture Courtesy: Petals Engineering Pvt ltd

Once you are done with machine setting, just move towards the second step which is supplying material to the machine. In addition, load the filling solution in machine hopper and attach a vial feeding conveyor to supply the machine during operation.

Vials Feeding

Vials feeding- Picture Courtesy: cozzoli.com

Now, the machine is ready to be started. As your injection vial filling machine is powered on, the glass vials will initiate gradual movement from feeding conveyor towards the machine. During this phase, the glass vials are responsibly transferred to machine with the help of rubber stoppering mechanism which pick and place the batch of vials to supply the machine with vials.

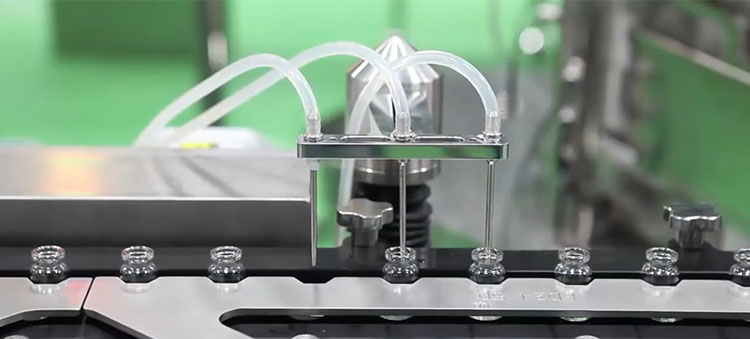

Vials Filling

Vials filling- Picture Courtesy: ambica.co.in

Proceeding further, these vials are moved ahead for filling where they are stopped under the filling heads. At this point, the machine start dispensing the precisely weighed volume of material into awaiting vials through nozzles. The filled batch of vials is then replaced with empty vials and the process goes on until desired number of vials are filled or operator stop the machine.

Vials Capping

Vials capping- Picture Courtesy: Petals Engineering Pvt ltd

In this step, the filled vials are brought by conveyor from filling station towards the capping unit. These vials are then provided with caps or stoppers and these caps are tightly sealed around their necks to create tight sealing.

Vials Discharging

Vials discharging- Picture Courtesy: Petals Engineering Pvt ltd

Finally, the finished injection vials are ready for outlet. With the help of conveying mechanism, these injection vials are discharged from the machine and processed further for packaging such as labeling and cartoning etc.

6.Describe The Structure Of An Injection Vial Filling Machine?

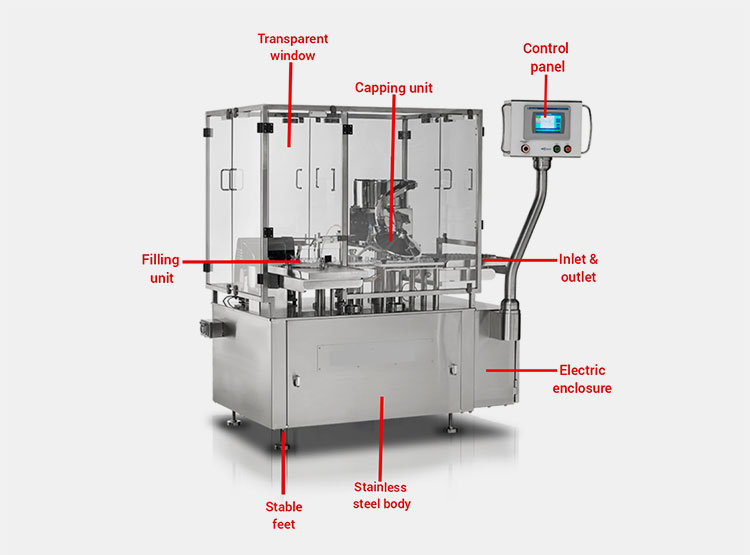

The structure of an injection vial filling machine is composed of several components which are described below:

Structure of an injection vial filling machine- Picture Courtesy: cozzoli.com

Transparent Window

The machine has transparent glass window that surrounds the working chamber and constitute upper structure of the machine. The purpose of this protection window is to keep the inside environment of machine free from environmental elements and allow user to conveniently administer the entire cycle of injection vials filling.

Filling Unit

Filling unit is the most important part of an injection vial filling machine. It consists of the hopper, weighing pump, and filling nozzles. Together, these components help in the accurate weighing of material and dispensing it into the vials through nozzles. The number of filling heads vary from one type of machine to another.

Capping Unit

It is another important component which is integrated into the machine for capping filled vials. It consists of a hopper, caps unscrambler, cap applicator, and sealing unit. This unit is responsible to seal the vials after filling. Depending upon the type of caps such as plastic caps or aluminum caps, the sealing method also vary as cap application and crimping sealing respectively.

Control Panel

It is the brain of the machine which picks information, stores it, and apply it in form of machine functioning. The control panel include a touch screen interface where multiple set of data is provided for operator convenience. Apart from it, knobs for emergency stop and power switch are also located here.

Inlet & Outlet

The machine has a separate path which works as a gateway for the entrance and exit of vials. The inlet is through which empty vials enter into machine and after they get filled and sealed, discharging take place through outlet station. Thus, a serialized system is adopted to avoid haphazard and product damage.

Electric Enclosure

Electric enclosure is consistent as the power house of an injection vial filling machine as it holds within it multiple electric tools such as wires, fuses, and other devices which collectively regulate the machine.

Stainless Steel Body

An injection vial filling machine has a stainless steel body comprising the main frame that support the other parts for their structural adjustment. It is fully sure against corrosion.

Stable Feet

The machine has multiple stable feet located under the main structure. These feet are helpful in ensuring stable performance.

7.What Are The Types Of An Injection Vial Filling Machine?

An injection vial filling machine can be broadly categorized into two types on the basis of material they fill. These types are explained below in detail:

Injection Vial Liquid Filling Machine

Injection Vial Liquid Filling Machine- Picture Courtesy: cozzoli.com

As the title illustrates, this type of injection vial filling machine is designed for filling liquid solution into vials. It can accommodate range of vials in an efficient manner. The machine is available in fully automatic and semi-automatic technology and can be simply integrated with other machines to make production line.

Structure

The structure of machine is composed of several units including a liquid filling unit, capping unit, conveying system, electric system, and main frame etc.

Working Process

It simply works by taking empty vials and processing them through filling and capping unit. The weighing of filling material is done automatically during operation.

Injection Vial Powder Filling Machine

Injection vial filling machine for powder- Picture Courtesy: romaco.com

Injection vial powder filling machine is another type of equipment which is specialized in filling vials with injectable powders. The machine features different systems to carry out the powder filling and it supports various types of capping and vials such as aluminum capping. The speed of machine is higher as compared to liquid injection vial filling machine with output ratio of finishing up to 24,000 in an hour.

Structure

The structure of machine is simple with main components including a hopper, filling heads, main frame, capping station, and control system etc.

Working Process

It works automatically by transforming the empty vials into finished one by passing them through filling and capping.

8.Differentiate Between An Injection Vial Filling Machine And An Injection Ampoule Filling Machine?

While injection vials and injection ampoules are often considered the same, there is much difference between both types of packaging containers. Similar is the case with machines which process these containers. That's why, it is important to mark distinction line between an injection vial filling machine and an injection ampoule filling machine. These differences can be simply understood by looking into the table below:

| No | Factors | Injection Vial Filling Machine | Injection Ampoule Filling Machine |

| 1 | Definition | Injection vial filling machine is designed to deal with glass vials for filling injectable material. | While as, injection ampoule filling machine is employed to carry out the filling of ampoules. |

| 2 | Structure | Its structure is comparatively precise with few major components. | On the other hand, it has complicated structure with separate stations for filling, heating, and sealing. |

| 3 | Process | Its process is simple with major steps of material filling and vials capping. | In contrast, it follows long operation of nitrogen flushing, preheating, filling, flaming, and sealing. |

| 4 | Used for | It is used for both liquid and powder solution. | While as, it is only applicable to liquid injectable solution. |

| 5 | Sealing method | It employs capping method for closing vials. | It uses heating method for sealing where glass is molten and fused for creating seal. |

| 6 | Picture |

VR840S – Liquid Filling & Stoppering Machine- Picture Courtesy: cozzoli.com |

AIPAK ENGINEERING- AKA series ampoule filling and sealing machine |

9.Highlight The Applications Of An Injection Vial Filling Machine?

An injection vial filling machine has wide application in various fields. Some of the prominent sectors are highlighted below:

Pharmaceutical Industry

Doctor infusing injection in vials- Picture Courtesy: gerresheimer.com

The use of an injection vial filling machine is inevitable in pharmaceutical industry where the production and processing of drugs is a routine task. Thus, to carry out packaging of injectable solutions, this machine is the first priority of pharmacists that provide extra safety and efficiency.

Nutraceutical Industry

Nutraceutical medication presentation idea- Picture Courtesy: medlineplus.gov

With unstoppable advancements, now its not only the therapeutic drugs which can be infused into human body rather vitamins, minerals, and amino acids are also included among them. So, what here significant is to highlight that an injection vial filling machine is also applicable in nutraceucal industry.

Veterinary Industry

Doctors holding pets- Picture Courtesy: vetpracticemag.com.au

Injection is considered one of the convenient ways to conduct animal treatment as solid dosage form like tablets and capsules are hardly swallowed by them. Thus, veterinary injections are commonly produced in veterinary industry for which machine like injection vial filling machine is a must have equipment.

Beauty Care Industry

Various beauty injection vials

Every other day, we see new ways being introduced for enhancing the external beauty. Among them, injectable solutions are becoming rapidly famous. Thus, for the preservation of these injectable liquid and powders, an injection vial filling machine can be simply employed in beauty care industry.

Chemical Industry

Chemical representation- Picture Courtesy: chemindigest.com

Chemicals need enclosed environment to be dealth with or else they may cause physical harm. In this way, vials are popularly used for the storage of various liquid and powder chemicals because of its simple operation and safe handling. Hence, we can say that chemical industry is also among the beneficiaries of an injection vial filling machine.

10.What Other Machines Can Be Integrated With An Injection Vial Filling Machine?

Well, there are wide range of machines which can be integrated with an injection vial filling machine. These machines are enlisted below:

Ultrasonic Washing Machine

AIPAK ENGINEERING- AKCA series vertical ultrasonic washing machine

Ultrasonic washing machine is one of the important machines that can be integrated with an injection vial filling machine for disinfecting the glass vials. It has heavy-duty structure which is composed of several units including an ultrasonic unit, washing system, and vials conveying mechanism etc. It simply works by holding the glass vials in clamps which move these vials through washing phase.

Sterilization Tunnel

AIPAK ENGINEERING- AKDH series hot air circulation sterilization tunnel

Sterilization tunnel is yet another significant machine pivotal for the sterilization of injection vials. Its structure resemble a tunnel which has several sections for the intermittent drying, heating, and cooling of glass vials. These units greatly help in removing the bacteria and pyrogens which may be present in the vials. Thus, it provides the injection vial filling machine with fully purified glass vials.

Bottle Labeling Machine

APC-T1 Round Bottle Side Face Labeler- Picture Courtesy: Allpack

Bottle labeling machine play important role in applying labels to the finished vials. It is made up of main frame, label reel holder, control panel, conveyor, fir brush, label pulling mechanism, sensors, and label cutter etc. It works by unwinding the label from reel through multiple pulleys after which the label is cut of through cutter and applied around the injection vial. Hence, this machine can be attached to an injection vial filling machine.

Bottle Cartoning Machine

Full Automatic Bottle Cartoning Machine- Picture Courtesy: Allpack

Packaging is a critical step in the preservation and safety of goods. Similar is the case with injection vials which must be properly packed for safe handling throughout transportation. In this way, bottle cartoning machine is of paramount importance that can be integrated with an injection vial filling machine. This equipment has simple body with few components including a carton magazine, flappers, conveyor, and main frame etc. In the same manner, it follows easy way from forming carton, packing the injection vials into it, and finishing it through flaps closing.

11.How To Clean And Maintain An Injection Vial Filling Machine?

Cleaning and maintenance are the key steps that must be fulfilled by operators and the same goes for an injection vial filling machine. So, we have explained these two steps for you along with some guiding tips. Make sure to understand them thoroughly:

Operator maintaining the machine- Picture Courtesy: Syntegon

Cleaning:

- Disassemble the detachable parts of machine like hopper, filling heads, and capping device for accurate cleaning.

- Use recommended cleaning agent for washing and removing out the dirt, debris, and residues.

- For external and other sensitive parts, use soft damp cloth to clean the surface.

- Once, you have cleaned all the parts, make sure to dry them well and locate them on their proper areas. For this, you can also take the help of operation manual.

Maintenance:

- Keep your machine structurally maintained and check it each time before starting operation.

- Conduct the setting of machine parameters whenever you process new batch to avoid filling inconsistencies.

- Keep the movable parts of machine lubricated to avoid friction and parts wear and tear.

- In case of parts damage, replace the defected parts timely before the affect other tools.

- During operation, keep observing the machine functioning and voice. If you find any abnormality, stop the machine and try to find the root cause for troubleshooting.

12.Explain The Troubleshooting Of An Injection Vial Filling Machine?

It is obvious that at any point your injection vial filling machine may show abnormality due to some technical fault. So, there is no need to rush. You just have to identify the problem, know the cause, and take relevant action. In this way, below troubleshooting explanation can be helpful for you:

Inconsistent Filling

Inconsistently filled injection vials

This is a common problem which is prevalent in both liquid and powder filling for injection vials which is caused by following reasons:

Cause:

- Wrong calibration of the filling system.

- Uncleaned filling heads which causes blockage.

- Fill volume is not settled in control panel.

Solution:

- Make sure to calibrate the filling system that is compatible to the filling material.

- Clean the filling nozzles in order to remove residues for smooth flow of material.

- Set the fill volume through parameters setting in control penal.

Vials Breakage During Operation

Broken injection vial- Picture Courtesy: apsf.org

During the operation, the vials may break or get damaged due to conveying for which several reasons are there:

Cause:

The rubber holders for holding vials may be loose which result in the shaking of vials that may damage or break them.

The size of the vials is too small then the rubber holder used for their holding.

Solution:

Tight the screws of vials rubber holder.

Make sure to use the compatible size vial rubber holder with changing size of vials.

Capping Error

Various types of caps for vials- Picture Courtesy: romaco.com

The filled vials are not properly capped.

Cause:

The large space between vial and cap applicator results in missing caps over vials.

Using inappropriate size of caps causes loose capping.

Inadequate or excessive sealing pressure for capping may result in poor capping.

Solution:

Reduce the distance between vials and cap by adjusting the cap chute.

Use the appropriate size of caps.

Adjust the sealing pressure for strong sealing of caps.

13.Factors Responsible For Choosing An Ideal Injection Vial Filling Machine?

Selecting an ideal injection vial filling machine require you to be on the ideal level to have clear understanding of several factors including:

Type of Filling Material

Powder & liquid filled vials- Picture Courtesy: romaco.com

What type of filling material do you want to process? Is it powder or liquid? Answering these questions will simply help you to scrutinize an ideal machine for you. Similarly, you can further go into the details of material nature like whether is it free flowing or adhesive as these factors influence the type of machine you will use.

Production Level

Large number of COVID-19 vaccine vials- Picture Courtesy: usatoday.com

Now, another critical aspect is to look for your current production level. It ask you to have a look on your manufacturing scale which can be on small scale, medium scale, or large scale. Similarly, understanding this will enable you to opt for either semi-automatic, fully automatic machine, or full fledged injection vial filling line.

Containers Specifications

Do you want to process only same size of vials? Or is there any variation in their size? Similarly, the question can be on part of the vial caps which can be plastic or aluminum and both need entirety different capping technique. So, make sure to determine your preference before opting for any machine.

Quality Certification

Quality certification icon- Picture Courtesy: Shutterstock

Last and yet most important thing to look for is the quality of machine. Now, it can be check by assessing the certification of machines which must include ISO, FDA, GMP, and EU. Along with this, supplier reputation, experience, and warranty policy are other facets of the coin to ensure quality of the machine.

Conclusion

So, let's wrap up this composite FAQ guide about an Injection Vial Filling Machine. We hope, this review has been a source of information and motivation for you to not only the user of an injection vial filling machine but be the master of it! The significance of the machine is hidden from no one especially in pharmaceutical, veterinary, and chemical industry. Thus, it is necessary to choose the machine after thorough research. In this way, we can help you in finding your ideal injection vial filling machine by presenting you world class machines at AIPAK ENGINEERING. You can simply approach us through our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours