Ampoule Filling Line: The Complete FAQ Guide In 2025

Ampoules provide safe and convenient way for the storage and preservation of liquids in various industries. The provision of hygienic environment of the glass helps in prolonging the shelf life of sensitive and sterile fluids. That's why, manufacturers across the globe are preferring the use of ampoules for the packaging of their produced drugs, serums, and chemicals etc.

In this way, the trickiest problems which they encounter are the precise filling as well as sealing of ampoules. Together with the need for efficiency, an Ampoule Filling Line is designed to end all the worries. This innovative solution offers extremely comprehensive performance by accomplishing multiple tasks. Not only that, but its working process, maintenance, and troubleshooting are also very easy. So, make sure to dive deep into this FAQ guide about Ampoule Filling Line!

1.What Is Meant ByAmpoules?

Ampoules containing different fluids- Picture Courtesy: darmastir.com

Ampoules simply refer to the small glass bottles which are used to store aqueous solutions in different sectors especially in medical industry. These tiny containers have small tube shape body with a narrow tip. Due to their enhanced hygienic level and durability against environmental elements, ampoules are always considered perfect to preserve drugs, chemicals, and beauty care liquids.

The shape and size of ampoules vary slightly, however, their packaging involves the same steps of washing, filling, and sealing etc., for which an ampoule filling line is designed.

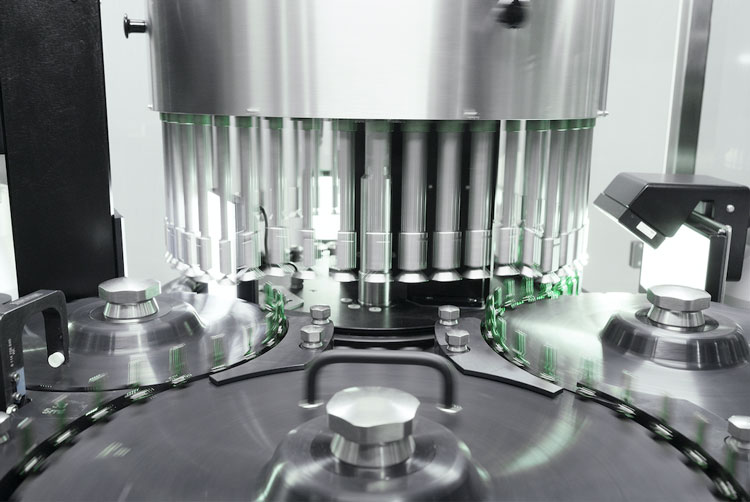

2.Define An Ampoule Filling Line?

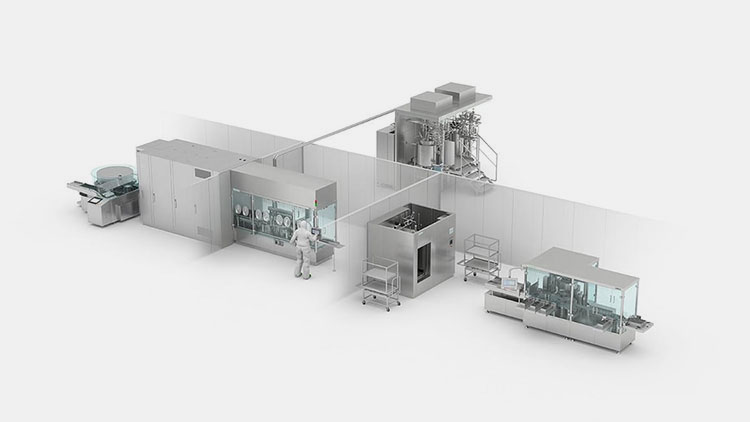

Allpack- High Quality/Output/Precise 1-20ml Ampoule Filling Line

Ampoule filling line is high-speed, composite industrial solution employed for the complete processing of ampoules. It encompasses multiple machines integrated in a single line such as ultrasonic ampoule washing machine, ampoule dryer sterilizer, and ampoule filling and sealing machine.

Together these units enable the ampoule filling line to carry out the task of ampoules washing, sterilization, drying, filling, and sealing in one go. This equipment is the state-of-the-art creation which provides a sustainable and enclosed environment for the safe packaging of ampoules. The entire working mechanism of the line is automatic which can better deal with the changing size and volume of ampoules and liquids respectively.

3.How An Ampoule Filling Line Can Benefit Your Business?

When it comes to discuss the essence of ampoule filling line for your business, some of its aspects must be highlighted in order to identify its potential and worth. So, let's enumerate the features of ampoule filling line and how they can help you in elevating your current growth as well as the quality of production!

Multifunctional

Ampoule sealing and discharging- Picture Courtesy: syntegon.com

An ampoule filling line is a comprehensive solution with multitasking capabilities. It can perform various functions in one run by spraying water into inner and outer side of the ampoules for washing. Similarly, it undertakes the sterilization, nitrogen flushing, liquid filling, and ampoule filling simultaneously.

Boost Production

Large number of finished ampoules

This sophisticated solution can better address your concerns regarding the expected production targets. With automatic system and quick parts changeover, it supports continuous working. Eventually, it can produce thousands of ampoules in an hour at an extremely high rate while meeting the hygienic and safety standards.

Enhanced Safety

Ampoules are considered inevitable to preserve the vary medications prepared in pharmaceutical industry. At the same time, their delicacy makes it challenging to conduct undamaging packaging. But this fear has simply ended with the use of an ampoule filling line which provide an enclosed environment for the safety of both the ampoules as well as drugs to maintain their sensitivity.

High Precision

Precise sealing of ampoules- Picture Courtesy: cozzoli.com

Precision and accuracy are the two facets of same coin which are considered core elements in healthcare industry. Since, an ampoule filling line is more than just an automatic solution, its super intelligent monitoring capabilities enable it to conduct a real-time accurate processing mechanism by detection and rectification of errors. Eventually, the ampoules finished by it depicts high accuracy filling, sealing, and packaging.

Convenient Handling

Women holding ampoule in hand- Picture Courtesy: laboratoriosbabe.com

Dealing with such a giant production line may seem horrible but that's not the case with an ampoule filling line as it is pretty easy to handle. For instance, the line has easy-to-use operation mechanism where operator is only required to observe the process once it loaded and settled. Similarly, it has simple maintenance schedule and lower chances of technical issues, preventing unnecessary indulgence.

Adaptability

Various sizes of ampoules- Picture Courtesy: beautyontheduty.wordpress.com

An ampoule filling line can also benefit you by dealing with range of ampoules sizes, shapes, and filling volume. So, you can easily process your B type, C type, D type, and other forms of ampoules.

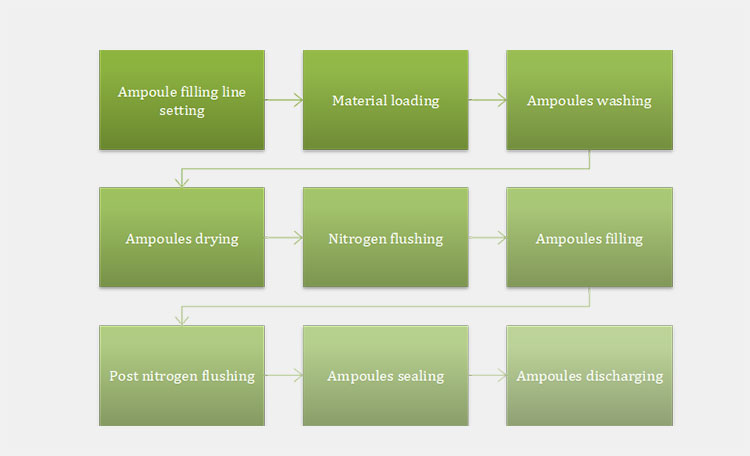

4.Explain The Working Principles Of An Ampoule Filling Line?

Although, the working process of an ampoule filling line seems complicated due to the inclusion of long-standing machines, however, it can be simply understand by breaking down these working principles into simple steps. These are as follows:

Ampoule Filling Line Setting

Operator setting the ampole filling line- Picture Courtesy: Pharmec

It is mandatory for every machine that it must be properly fixed before operation. Similar is the case with an ampoule filling line which needs to be adjusted both structurally and by parameters. It can be easily set by using the touch screen penal located at each unit. So, adjust the temperature requirements, fill volume, and sealing specifications etc.

Material Loading

Ampoules loading- Picture Courtesy: iven-pharma.com

Once you are done with the basic setting of your ampoule filling line, just supply the glass capillaries to washing unit, add a water connection to the ultrasonic washing machine, and load the filling liquid (medicine) into the filling machine hopper. Now, your ampoule filling line is ready to be started.

Ampoules Washing

Ampoules washing- Picture Courtesy: Dara Pharma

Ampoule washing is the first step that takes place when equipment is powered on. Here, the empty ampoules are passed through several stages to let them free from contamination. The ampoules are holded into turntable whose rotation helps in their washing by circulating water. Ampoules are properly cleaned by simultaneous inner and outer washing of amouples with the help of water induced by compressed air.

Ampoules Drying

Ampoules washing- Picture Courtesy: Pharmec

This is one of the major steps of an ampoule filling line working which is also called sterilization phase. It involves the sterilization of washed ampoules through drying and application of intense heat in order to remove out the possible existence of pyrogens.

For this purpose, the washed ampoules are transferred to mesh belt which carry the glass ampoules to high temperature zone. Here, these ampoules are exposed to high temperature of 250- 350 C° to ensure pyrogen free outcome. Afterwards, these ampoules are passed through the cooling zone to cool them down to normal temperature.

Nitrogen Flushing

Now, when ampoules are properly sterilized against contamination, the next step is nitrogen flushing. Nitrogen flushing is important for the reason that it eliminates the oxygen from ampoules and provide safe room for drug storage.

Ampoules Filling

Ampoule filling- Picture Courtesy: ROTA

At this point, ampoules are conveyed to the filling station right under the filling nozzles. This section is fully protected and enclosed to ensure safe delivery of liquids into ampoules. The aqueous solution is firstly measured by the machine and then precise volume is discharged into awaiting ampoules via narrow tubes.

Post Nitrogen Flushing

To ensure further protection, post nitrogen flushing step is carried out where the liquid filling ampoules are exposed to nitrogen flushing.

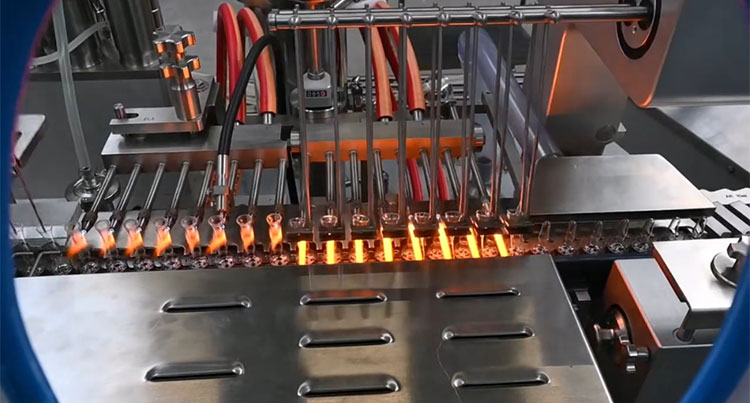

Ampoules Sealing

Ampoule sealing- Picture Courtesy: ROTA

Moving forward, the nitrogen flushed ampoules are sealed by the sealing unit. The sealing takes place with the help of heat generated by the torches of brush fire track. Consequently, the top tip of glass ampoules begins melting, resulting in the creation of stringent sealing.

Ampoules Discharging

Ampoules discharging- Picture Courtesy: ROLSTECH

In the last step, finished ampoules are ready for outlet. Thus, these ampoules are discharged by the machine.

5.What Machines Constitute The Structure Of An Ampoule Filling Line?

An ampoule filling line is made up of three major machines which are themselves product of subcomponents. Therefore, to properly understand the parts of an ampoule filling line, it is necessary to know the structure and composition of each unit which is described below:

Vertical Ultrasonic Washing Machine

AIPAK ENGINEERING- AKCA series vertical ultrasonic washing machine

Vertical ultrasonic washing machine constitute the first unit of an ampoule filling line. It plays eminent role in disinfecting the glass capillaries by thorough washing and rinsing steps. The structure and functions of the machine can be better understood by looking into its components such as:

Washing Chamber:This is the main part where actual washing of the ampoules take place. The chamber has a transparent window which surrounds the washing area. Inside it, the rotary turret is placed which holds the ampoules.

Conveying Mechanism:It refers to the feeding inlet as well as other parts such as mesh belts and ampoule out feed which help in the convenient mobilization of ampoules from one place to another.

Control System:The vertical ultrasonic washing machine is driven by AC motor, frequency conversion speed regulator, and touch screen interface. These components energize and regulate the functioning of machine.

Water System:Water system is another important mechanism of the machine which include the separate water tanks for distilled and detergent water, pumps, and water infusing nozzles etc.

Sterilization Tunnel

AIPAK ENGINEERING- AKDH series hot air circulation sterilization tunnel

Sterilization tunnel is another crucial part of the ampoule filling line. It is employed to fulfill the sterilization of washed ampoules through simultaneous drying, heating, and cooling in order to remove the moisture content and presence of pyrogens. The machine is made up of following parts:

Main Frame:The main frame of sterilization tunnel is durable which is made up of stainless steel body. It has several stable feet which helps in smooth placement over the surface.

Aur System:It composed of intake air system, exhaust air system, and internal air circulation. Together, they help in processing inside the tunnel.

Drying Unit:The drying unit of the sterilization tunnel perform the function of drying washed ampoules.

Heating Unit:It is responsible for heating the ampoules. The heat is produced by the heater current device which transform the electric current into heat.

Cooling Unit:This section is located at the end area whose task is to normalize the temperature of ampoules by cooling down.

Ampoule Infeed & Out feed:Ampoules infeed and out feed sections are used for the feeding and discharging of ampoules.

Ampoule Filling And Sealing Machine

AIPAK ENGINEERING- AKA series ampoule filling and sealing machine

Ampoule filling and sealing machine is the final and most important machine of an ampoule filling line. It is considered the core equipment in carrying out the ultimate task of ampoule filling and sealing. Therefore, its structure is a bit lengthy with several components including:

Feeding Unit:It is also called ampoule Infeed which is responsible for the sorting and transferring of bulk ampoules in a serialized manner. It also reduces the chances of ampoules jamming and breakage.

Protection Window:The machine has transparent protection windows on all sides to make the internal environment free from pollution and dirt while allowing for easy monitoring of the process.

Control Panel:It is a computer like device with touch screen display and certain knobs. Together, it enables the user to set machine parameters and control its functioning.

Gas Flushing System:Gas flushing system is integrated for the purpose of pre, and post has flushing in order to remove out the presence of oxygen and provide safe environment for drug preservation.

Conveyor Belt:Conveyor belts carry out the transmission of ampoules throughout the machine. It is responsible for taking ampoules from infeed, passing them through different sections of filling and sealing, and their discharging from machine.

Filling Nozzles:Multiple filling nozzles are fitted in machine to fill the liquid into ampoules. The number of filling heads vary from 8 to 12 in fully automatic machines.

Sealing Unit:This unit perform the sealing of filled ampoules. It consists of flame ignition and flow meter. The former ignite the fire while as the latter ensures a regulated flame. Moreover, gas safety valve is used to maintain the gases concentration.

Ampoule Discharging Unit:It is an outlet station where all the finished ampoules are collected for discharging.

6.Highlight The Sectors Where An Ampoule Filling Line Can Be Used?

The use of an ampoule filling line can be seen in every other industry being involved in any kind of sensitive liquid production. In this way, some of the popular sectors where an ampoule filling line can be used are enumerated below:

Pharmaceutical Industry

Therapeutic ampoules pack

Pharmaceutical industry is the top user of an ampoule filling line which is constantly engaged in producing large number of liquid medications apart from solid dosage form. That's why, ampoules are considered useful for the preservation of liquid pain medication, emergency drugs, nutraceuticals, and sedatives. Such large production targets can only be met by this sophisticated machine with enhanced safety level.

Veterinary Industry

Doctor treating pets- Picture Courtesy: Shutterstock

The importance of an ampoule filling line is also prevalent in veterinary industry where multiple types of pain relieving drugs are delivered in ampoules. As the concern for animal care is growing, demand for efficiency in drug production and packaging is also on rise. Thus, in such a scenario, fully automated filling line is always suitable.

Biotechnology Industry

Nature biotech- Picture Courtesy: Shutterstock

Although, biotechnology is a newly established field as compared to other fields, yet its importance is far reaching in making human lives better. With the help of research, technology, and use of natural resources, it is paving way for healthy human life. During this process, the need for preservation of living organisms and obtained products is required which is better fulfilled by an ampoule filling line.

Dermatology Industry

Ampoule essence for skincare- Picture Courtesy: colorholicsmarketplace.com

With advancements in technology, skin care treatment is not discussed under the separate field of dermatology industry. Similarly, the liquids produced for skin beautification including moisturizing ingredients, serums, spa agents, and anti-aging injection water are now delivered in ampoules. For the thorough packaging of these fluids, an ampoule filling line is an ideal solution.

Chemical Industry

Various chemicals in beakers & testing tubes- Picture Courtesy: nextmsc.com

Chemicals must be dealt with immense care especially when processed on large scale. To protect different types of liquid chemicals against air and contamination, ampoules are considered the best means for their storage. Since, an ampoule filling line offers a complete solution, there is no question left for its importance in the field.

7.How To Check The Quality Of An Ampoule Filling Line?

It is necessary to check the quality of an ampoule filling line in order to know the competitiveness of the equipment. Moreover, it is also useful for the durability of the machine which is a core aspect for modern day machines. In this way, we have enlisted few important quality standards which can prove that your ampoule filling line is a quality product. These include:

FDA quality standard icon- Picture Courtesy: contemporarypediatrics.com

GMP:Good Manufacturing Practices ensures that all the goods and products which are produced in medical industry must meet the general safety principles in order to eliminate health hazards and errors during manufacturing.

FDA:Food And Drugs Administration is USA based agency with primary purpose of ensuring public health by strictly regulating safety of the pharmaceutical, biological, and veterinary drugs as well as machines.

CE:Conformate European is a collective symbol that represents the safety aspirations of European Union countries. Thus, an ampoule filling line with CE certification is meeting all the safety requirements of EU.

ISO:International Organization for Standardization is an international organization established for the purpose of maintaining public safety by controlling the manufacturing of goods and machines.

8.What Is The Maintenance Requirements Of An Ampoule Filling Line?

The maintenance of an ampoule filling line is pretty simple because the equipment is requiring same steps of cleaning, lubrication, and setting which are necessary for every machine. However, it is important not to skip this important function on your part or your production line will display inefficiencies. So, let's know some maintenance tips!

Engineer maintaining an ampoule filling line- Picture Courtesy: Syntegon

Cleaning:Cleaning should be done on regular basis after the completion of daily filling of ampoules. For this, you need to conduct the cleaning of different machines one by one. First, disassemble the removable parts and wash them with clean water and recommended cleaning agent. Second, wipe out other parts with dump cloth like window and main frame. Lastly, let the machines dry and assemble the parts to relevant areas.

Setting:Make sure to set the parameters of each section of an ampoule filling line before starting the operation. Similarly, keep updating the software of control panel to get new features and avoid touch screen issues.

Repair & Replacement:It is possible that any part of the machine may get old or damaged. So, timely repair affected tools and replace the defective ones to eliminate unwanted problems.

Structural Adjustment: Make sure that your ampoule filling line is structurally adjusted. For instance, the tools of machine should be adjusted according to the size and shape of ampoules.

Lubrication:Lubrication is a crucial factor in the efficiency and life-expectancy of an ampoule filling line as it holds several rotating tools. These movable parts must be lubricated weekly and monthly to avoid friction, wear, and generate heat for effective performance.

9.How To Counter The Common Issues Related To An Ampoule Filling Line?

While operation an ampoule filling line, certain technical issues may obstruct the way for smooth functioning. In that case, it is crucial to identify the problem, find the root causes, and then take relevant action. So, we have highlighted some of the common issues along with their solutions which will surely be helpful. These are explained as under:

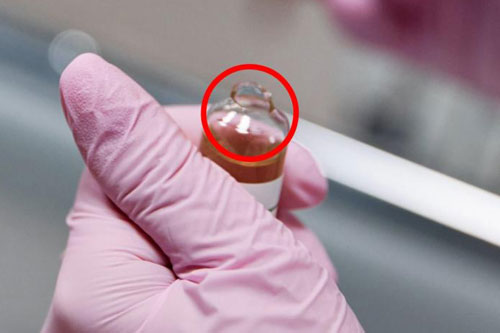

| i. Deformed head of ampoule | ||

Ampoules with deformed heads- Picture Courtesy: heuft.com |

Cause:

It is caused by the inadequate drawing of ampoule head during sealing due to insufficient flame. The bearing of ampoule holding is inflexible causing difficulty in its rotation. The wall of individual ampoule is extra thick. |

Solution:

Increase the fire power of front and rare flame to help melt the top of glass ampoule. Replace the new bearing or adjust the spring of ampoule grippers for their flexible moving. Use quality ampoules witj same consistency. |

| ii. Weak sealing | ||

Poorly sealed ampoule- Picture Courtesy: qlicksmart.com |

Cause:

Too high temperature can cause bubble like sealing which is easily breakable. The slow flame may cause incomplete sealing. The dwell time of sealing may be another cause for brittle sealing. |

Solution:

Reduce the flame to suitable level to avoid bubble formation. Increase the flame intensity for effective sealing. Increase the dwell time of sealing to let the glass melt and fuse properly for strong sealing. |

| iii. Ampoules breakage during operation | ||

Ampoule with broken head- Picture Courtesy: lookfantastic.com |

Cause:

The ampoules used are very thin to resist pressure. Rigidity of bearing holding the ampoules is a symbol of pressure increase which can break them. Clamps holding ampoules are rough. |

Solution:

Use ampoules of high quality. Adjust the bearing through spring fitted inside to increase the flexibility in rotating ampoules. Replace the clamps with new smooth ones. |

| iv. Variation in the fill volume | ||

Ampoules with different fill volume- Picture Courtesy: nordicpack.com |

Cause:

Blocked nozzles can cause poor flow of liquid. The parameters of machine is not fixed properly. There is an issue in filling nozzles. |

Solution:

Clean the filling nozzles and remove out dirt and residues. Set the fill volume through control panel each time before starting operation. Check the filling nozzles for damage and repair or replace if needed. |

| v. Foaming of liquid after filling | ||

Ampoule with foamy liquid drops- Picture Courtesy: apotheekenhuid.nl |

Cause:

The filling nozzles are unsuitable to the type of liquid filled. Increased pressure of filling may cause bubble in ampoules, eventually leading to foaming. |

Solution:

Use compatible nozzles in accordance with liquid type such as diving nozzles for foamy fluids. Reduce the pressure of filling, so that, liquid will get enough time to settle. |

10.What Is The Future Market Progression Of An Ampoule Filling Line?

The future market progression of an ampoule filling line is categorically promising. It can be simply understood by its ever increasing worth especially after COVID-19. Let's, ponder what factors play instrumental role in shaping the future market progress of an ampoule filling line!

Automatic ampoule filling line- Picture Courtesy: Syntegon

Firstly, the globalization has contributed a lot in enlightening people about the importance of drug safety which is dependent upon the use of effective machinery. It demonstrates that local manufacturers are now aiming towards the establishment of their own businesses and adopting the advanced technology used across the globe.

Secondly, the rapid pace of innovation in internet and AI are another potential factor which can surely influence the way how future ampoule filling line will be designed. They will be integrated with more advanced system for automatic functioning to enhance the efficiency as well as machine's ability to deal with diverse products and support self diagnosing.

Ultimately, it can be said that ampoule filling line in future may not bother humans for monitoring which can be done by robots. Thus, it may promote the use of minimal time, resources, as well as energy

11.Factors Responsible For Choosing An Ideal Ampoule Filling Line?

Whenever you want to plan a purchase of an ampoule filling line, make sure to consider some of the essential factors including:

Specifications

User checking machine features in control panel- Picture Courtesy: Syntegon

Specifications of an ampoule filling line such as the type of integrated filling system, number of filling nozzles, type of sealing, type of filling heads, and production efficiency vary from one type of equipment to another. Thus, knowing this will help you to choose the solution with flexibility to deal with various types of ampoules.

Types of Ampoules

Various types of ampoules

Ampoules are of different according to their size, breakage, and sealing. Similarly, the adjoined machine used in ampoule filling line must be in accordance with the type of ampoules you want to use. So, it you want to buy a standout equipment then pay heed to this factor and ask your vendor for compatible solution.

Supplier Reputation

The reputation of supplier is a key factor in choosing a quality machine. After all, the ampoule filling line is going to be your life long partner in business. So, make sure to find a trustworthy supplier. For this purpose, you can take help from the vendor experience in the field, history in providing services, quality certifications, and the customer feedback.

Budget

Considering budget- Picture Courtesy: uct-asia.com

Where does your current financial status lay? Answering this question can assist you to opt for the right solution. In addition, if you are new to the field but wishing to have full fledged production line, considering used solution will be a safe choice. In case, you are an experienced manufacturer in the field then new ampoule filling line can better fulfill your needs.

Conclusion

Let's wrap this detailed review about an Ampoule Filling Line: A Complete FAQ Guide In 2025! We are glad to have conveyed all the necessary information about the solution to you. The significance of an ampoule filling line can be easily found in areas dealing with any sort of sensitive liquids. Thus, for their protected packaging, this production is the best choice with automatic functioning, convenient handling, and quick troubleshooting. So, if you are eager to learn more or want to become the owner of sophisticated ampoule filling line, then don't forget to discover the inventory of AIPAK ENGINEERING!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours