Ampoule Machine: The Complete FAQ Guide In 2025

Hygiene and protection are the top priorities of pharmaceutical industries around the globe especially for liquid packaging. Here comes the need for ampoules which are fully safe to store therapeutic fluids and other stuff. To carry out this function, Ampoule Machine has been brought into the field.

This equipment is specialized enough to deal with various sizes of ampoules. By following simple operational procedure, sophisticated structure, and convenient maintenance schedule, Ampoule Machine is the ideal choice of every concerned manufacturer whether in field of medicine, food, or chemical. If you are also among one of them, don't skip exploring this comprehensive FAQ Guide!

1.What Is An Ampoule?

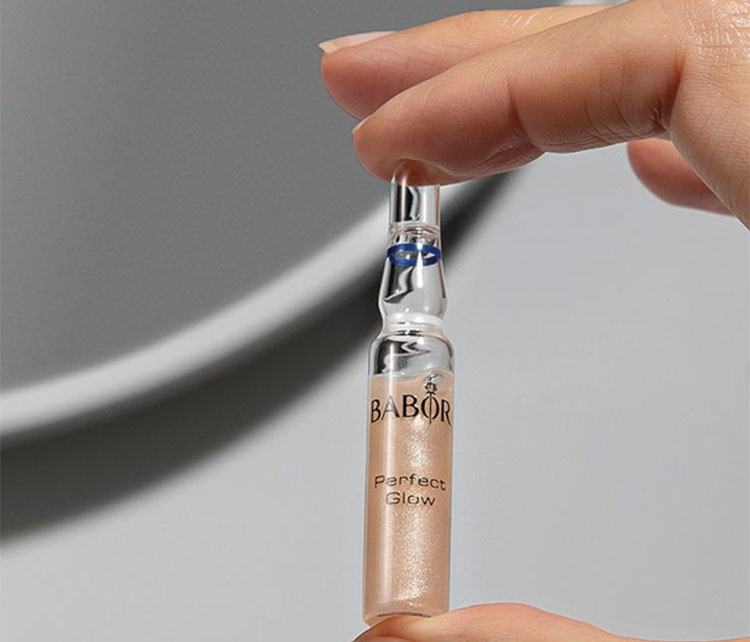

Ampoules containing liquids- Picture Courtesy: Babor

An ampoule is a small, sealed container made up of glass. Due to the airtight sealing and resistance to moisture and bacteria, it is usually employed for the preservation of liquid substances such as injection water, liquid medication, and chemicals etc.

It features a tube shape body part and a cap which are sealed using gas torches. Ampoules are widely applicable to liquids especially in medical industry, that's why, a particular machine is used to fill the liquid into ampoules and seal them which is known as ampoule machine.

2.Define An Ampoule Machine?

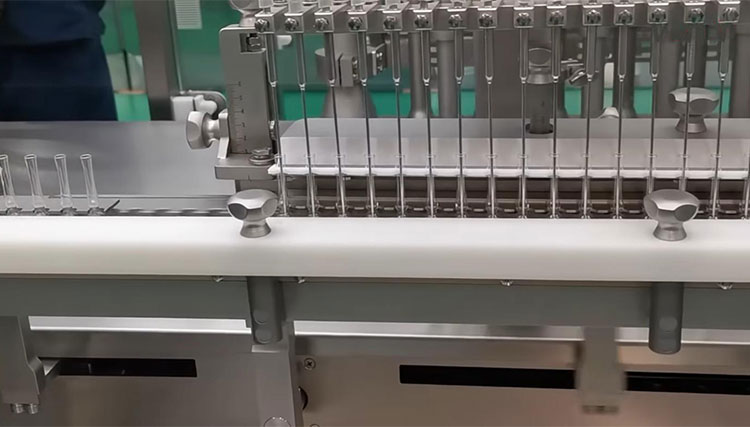

Aipak Engineering- Picture Courtesy: High Quality/Output/Precise 1-20ml Ampoule Filling Line

Ampoule machine refers to an advanced equipment tailored with astonishing features to carry out the task of processing ampoules. It performs the function by filling single dose of liquid into ampoule and then sealing it by using open flame.

The machine has automatic technology with easy-to-use operation. With its dynamic filling capability and efficient working, it supports multiple types of ampoules. Thus, ampoule machine can be used in different industries to fulfill the packaging of various sensitive fluids.

3.Enlist The Various Advantages Of An Ampoule Machine?

Ampoule machine features several characteristics which eventually enhance its advantages and help you transform your production. So, let's enumerate few of the notable benefits!

Dynamic Filling Capability

Small to large liquid filled ampoules- Picture Courtesy: informacionpublica.svet.gob.gt

Ampoule machines display a perfect dynamic capability in filling different liquid volume in ampoules. It is the result of advanced system which accept and regulate the commands set by operator and discharge accurately weighed volume into ampoules.

Multitasking

The machine is multitasking in a way that it simultaneously nitrogen flush, fill, and seals the ampoules. Along with this, it supports quick and automatic parts changeover with changing ampoule types such as b type or c type ampoules mouth. Thus, much can be done by using a single machine.

High Productivity

High production speed of ampoule machine- Picture Courtesy: Shutterstock

Increase in the production output is the dream of every manufacturer. Similarly, by using an ampoule machine, you can easily attain the aim with its high speed of finishing up to 15000 ampoules per hour.

Enhanced Safety

Precisely finished ampoule- Picture Courtesy: Babor

With quality stainless steel body and enclosed structure, the machine plays instrumental role in providing safe environment for the processing of ampoules. It is fully safe against corrosion and microorganisms itself and ensure product safety for lifetime due to precise liquid filling and stringent ampoules sealing.

Automatic Operation

Automatic operation of an ampoule machine- Picture Courtesy: Iven Pharmatech

Ampoule machine has automatic and up-to-date technology which makes its operation run easily without any special skills. The precise tooling system and integrated system of PLC and sensors help in controlling the functioning of machine.

4.What Are The Sealing Methods For An Ampoule Machine?

An ampoule machine may employ one of the two sealing methods for the sealing of filled ampoules. These are enlisted below:

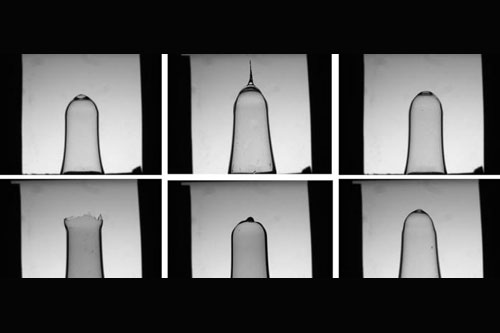

Tip Seal Method

Tip sealed ampoules- Picture Courtesy: real simple.com

Tip seal method is one of the popular sealing methods employed for ampoule sealing. It is done by melting the glass top of ampoule downward. During sealing, the ampoule is in constant rotary position to create smooth round seal. Thus, the sealed ampoules are hemispherical with strong sealing and uniformity in height as well as shape.

Pull Seal Method

Pull seal method- Picture Courtesy: us.phyto.com

Pull seal method is a method which is characterized by a tip on the top of glass ampoule. It is carried out in a way that heat is applied to the middle of neck and the melted glass is stretched upward, resulting in the creation of seal with sharp or hanging tip. That's why, ampoules sealed through this method are often irregular in shape and height

5.What Type Of Ampoules Are Supported By An Ampoule Machine?

An ampoule machine can process wide range of ampoules. These can be be simply known by looking into the underlying explanation:

Types Of Ampoules Based On Shape

Form B Ampoule

Form B ampoule- Picture Courtesy: nipro-group.com

Form B ampoule is a specific type of glass ampoule which is also known as straight-stem ampoule. These ampoules have straight neck with precise shape consistency. With strong resistance against thermal shocks, these ampoules are innovative creation of the latest technology which are easily filled and sealed by an ampoule machine.

Form C Ampoule

Form C ampoule- Picture Courtesy: nipro-group.com

Form c ampoules are conventional type of ampoules which can be distinguished from other types due to its wider opening. These ampoules are also called funnel type as their opening resemble funnel.

Form D Ampoule

Form D ampoule- Picture Courtesy: nipro-group.com

Form d ampoules are referred to as closed ampoules. Such ampoules are already closed, thus skip washing, drying, and depyrogenation step during processing. Thus, they are employed only for injectables that do not require aseptic filling. However, the use of form d ampoules may pose the risk of getting contamination.

Types Of Ampoules Based On Breakage

One Point Cut Ampoules

One point cut ampoule- Picture Courtesy: fs50glass.com

In one point cut ampoules, small incisio or cut is marked on their bulbous part around neck. This colored score shows the breakage point. Thus, one point cut ampoules provide safe and easy way for breaking of ampoules while eliminating the hazard of splintering and rough edges.

Color Break Ring Ampoules

Color break ring ampoules- Picture Courtesy: medikepack.com

As the name indicates, color break ring is another type of breakage which can be processed by an ampoule machine. It is done by creating a colored ring around the ampoules construction. Hence, it helps in the smooth cutting of ampoules.

Score Ring Ampoules

Pre-scored ring ampoules- Picture Courtesy: carlroth.com

Pre-scored ring ampoule is yet another convenient way for the breakage of ampoules. These ampoules have pre-scored rings around their neck which makes it easy to open them for use.

6.Explain The Working Mechanism Of An Ampoule Machine?

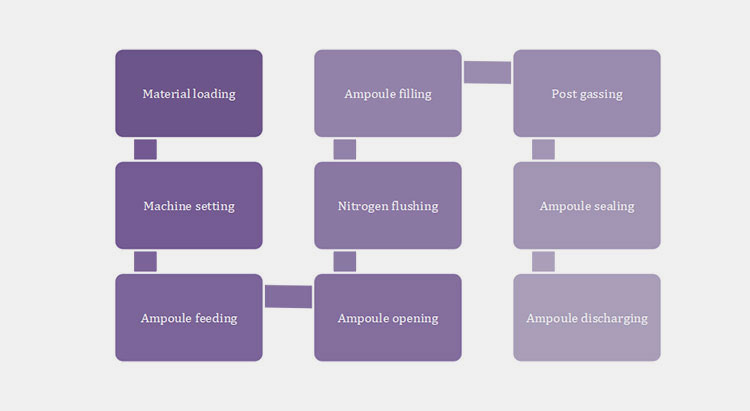

An ampoule machine follows several steps to carry out the ampoule filling and sealing. This working mechanism can be better understood by looking into the underlying explanation:

Material Loading

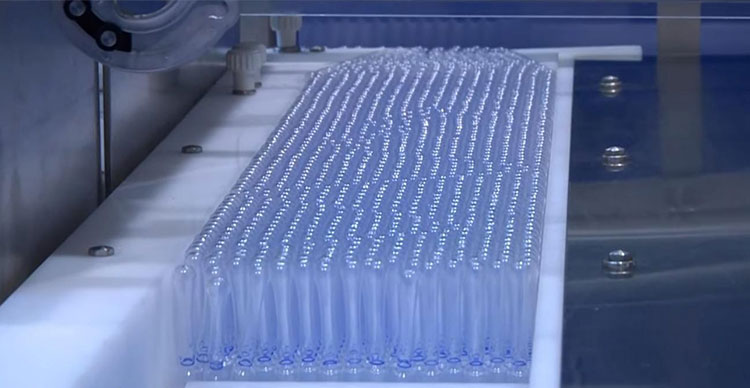

Ampoules loading

The ampoule packaging first requires proper loading of the material into machine which includes the liquid and empty ampoules. Liquid solution is loaded into the hopper from where the machine takes liquid during operation. Similarly, stock of empty ampoules is supplied to the machine via conveyor.

Machine Setting

Now, the second essential step of ampoule machine setting is supposed to be carried out responsibly. It simply involves setting the parameters and configurations of machine such as the amount of liquid to be filled in each ampoule, nitrogen flushing time, preheating and sealing temperature and other structural adjustment.

Ampoule Feeding

Ampoules feeding- Picture Courtesy: Iven Pharmatech

Once the machine setting gets done, it is ready to be started. As the machine is powered on, conveyor will start feeding empty ampoules to the machine via ampoules feeding screw.

Ampoule Opening

Ampoule opening

Moving forward, these empty ampoules are passed through preheating step for their opening. It is done when the heat generated by the ampoule machine touches the top of ampoules. Resultantly, the glass started melting and ampoules are opened. This step is included only for closed ampoules.

Nitrogen Flushing

Nitrogen flushing

These ampoules are now mobilized towards pre-gassing through transport system where they are sterilized after thoroughly undergoing nitrogen flushing. This step is significant for removing out the oxygen and other undesired elements present in ampoules.

Ampoule Filling

Ampoule filling- Picture Courtesy: Iven Pharmatech

At this point, the ampoule machine start weighing the exact volume of liquid and precisely dispense it into awaiting ampoules. Depending upon the number of filling heads, batch of filled ampoules is replaced with empty one and the process is continued until desired number of ampoules are filled.

Post Gassing

After filling, ampoules are once again exposed to gas flushing in order to eliminate possible presence of oxygen and enhance their sterility.

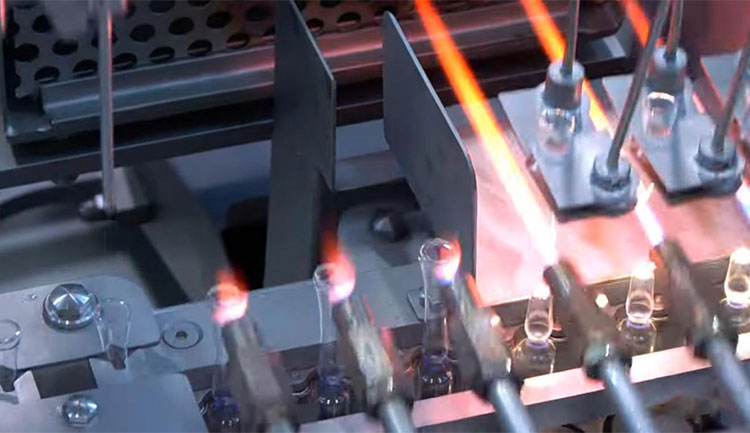

Ampoule Sealing

Ampoule sealing

As the filling and post gassing gets completed, the filled ampoules are hermetically sealed. This step involves preheating through which the top side of ampoules is molten. Similarly, the heated glass is fused, and tamper evident sealing is created over the top side of ampoule.

Ampoule Discharging

Ampoule discharging

Finally, all the finished ampoules are one by one discharged from the machine through conveyor and mobilized for further processing of labeling and packaging.

7.Describe The Structure Of An Ampoule Machine?

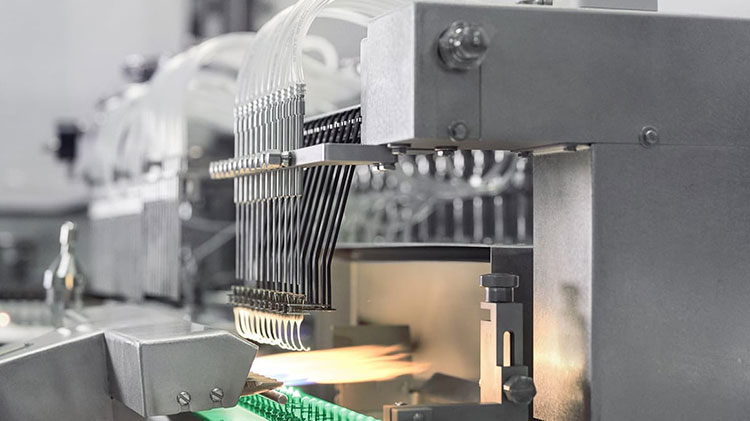

An ampoule machine is made up of several components each performing specific task. These parts along with their functions are enlisted below:

Structure of AKA series ampoule filling and sealing machine- Picture Courtesy: AIPAK ENGINEERING

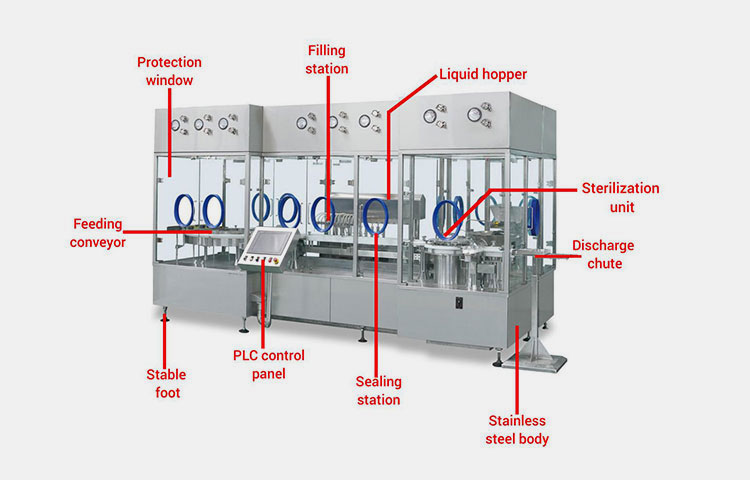

Feeding Conveyor

It is the infeed conveyor located at the start of machine. Here, bulk of empty ampoules are loaded to provide the machine with ampoules during operation. It is a turntable which responsibly feed the ampoules to machine keeping in view their sterility.

Protection Window

The machine has transparent protection windows which surround the working chamber. It thus ensures the safety of ampoules by eliminating the exposure to environmental elements and also greatly help the user in the convenient administration of machine working.

Filling Station

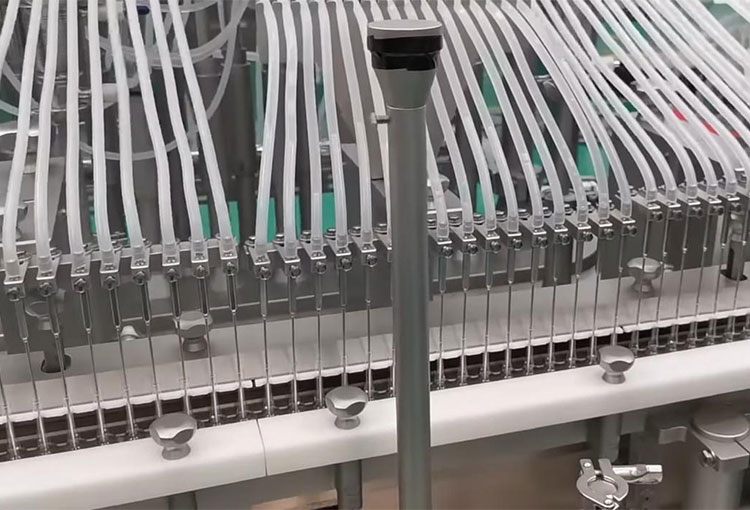

Filling station comprises filling nozzles which are attached to the hopper. They are responsible to accurately fill the liquid volume into the awaiting ampoules. The type of filling system depends upon the nature of liquids being used.

For instance, straight-through nozzles can be used for variety of liquids. Similarly, purge nozzles are suitable for extra sensitive liquids to maintain hygiene by removing air before and after filling. While as, overflow filling nozzles are good for filling volume at consistent level.

Liquid Hopper

Liquid hopper is a reservoir in which large volume of liquid is loaded before starting the machine. Thus, it provides the machine with liquid during operation.

Sterilization Unit

It is another important component of the ampoule machine which features different tools for sterilizing ampoules before and after filling such as washing and wiping etc.

Stable Foot

The machine has multiple feet which are located in its base. Together they add into the stability of machine over surface, so that, it will not vibrate or shake during operation.

PLC Control Panel

Programmable logic controller is one of the core components of an ampoule machine which is responsible to administer the machine working. The device can be used to make important setting in machine including fill volume, filling speed, sealing temperature, and data memorization etc. Operator can simply control the machine by using PLC control panel.

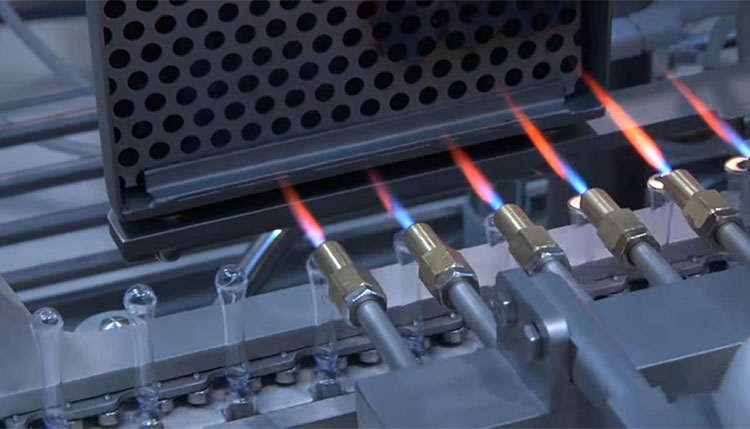

Sealing Station

Another important part of an ampoule machine is sealing station. It features several tools to carry out sealing task among which the core component is burner which is also known as brush fire head. It emits fire which melt the glass of ampoule head and eventually the sealing process is done after the removal of excess glass from top.

Stainless Steel Body

The machine is made up of quality stainless steel which is fully protected against corrosion and bacteria. Therefore, it is safe for dealing with all kinds of soft and abrasive liquids such as medication and chemicals etc.

Discharge Chute

It is the finished product outlet of an ampoule machine through which the filled and sealed ampoules are discharged to collection container for further packaging.

8.Highlight The Applications Of An Ampoule Machine?

Ampoule machine is widely applicable to rang of industries and its use has transformed these industries. Some of the notable sectors where the use of ampoule machine is inevitable are enlisted below:

Healthcare Industry

Various forms of drugs- Picture Courtesy: Shutterstock

Ampoule machine is extensively used in healthcare industry to pack variety of liquids and pastes. The common example is storage of vaccines, liquid medication, and syringe water which need hygienic environment for sterility retention. Now, it is only possible with the use of hygienic glass ampoules. Similarly, ointments, syrups, and other therapeutic fluids are easily packed in ampoules by using this machine.

Veterinary Industry

Doctor treating cow with injection- Picture Courtesy: shimadzu.at

As health treatment is not limited to humans only, the need of an ampoule machine can also be realized in veterinary industry. In this way, it plays an instrumental role in the preservation of liquid veterinary medication in form of ampoules. Moreover, it also enhances the efficiency of production which is the modern day need of industries.

Biotechnology Industry

Biotechnology industry- Picture Courtesy: baselaunch.ch

Biotechnology industry has also a great need for the use of an ampoule machine for the preservation of different substances such as genes, antibodies, plasma, and yeast etc. The machine provides safe means of storing and delivery of sensitive materials which otherwise may lose their potential.

Chemical Industry

Various chemical ampoules- Picture Courtesy: us.vwr.com

Most of the chemicals are considered hazardous for human health, especially, during their packaging as they may flow into air and get into the employee eyes. Thus, to avoid the reaction of chemicals as well as retaining their essence, an ampoule machine is best suitable which is fully corrosion resistant and provide safe environment for their processing.

Cosmetic Industry

Cosmetic liquids presentation idea- Picture Courtesy: coreelle.com

Cosmetic industry is another beneficiary of an ampoule machine due to its production and processing of wide range of liquids such as serums, hair dyes, cream, gel, shampoo, and moisturizer etc. Hence, to pack these fluids in handy plastic and glass containers, this machine is ideally suitable.

9.What Quality Standards Should An Ampoule Machine Meet With?

An ampoule machine should meet with certain renowned quality standards in order to be termed as quality machine. These standards are established by international organizations to ensure the safety of machine and enhance its compliance. So, let's know some of the prominent regulatory standards for ampoule machine!

Quality icon- Picture Courtesy: kca enterprises

ISO:International Organization for Standardization is the most popular quality standard with presence in over 160 countries. Its primary aim is to grant certification to only those goods and equipment which are adhering safety regulations.

SGS:Headquartered in Geneva, General Society of Surveillance is a multinational company which provides the services of inspection, verification, and testing. Thus, an ampoule machine certified by SGS means that it has fulfilled the necessary requirements for safety.

CE:Conformate European is a joint symbol that represents the collective will of European Union countries. An ampoule machine with CE mark shows that it is meeting the overall safety regulations set by EU.

GMP:Good Manufacturing Practices is an aspect of quality assurance which is established to ensure that all the medicinal products and equipment are consistently manufactured. Hence, an ampoule machine must be adhering these principles.

10.What Are The Maintenance Tips For An Ampoule Machine?

To ensure that your ampoule machine is always in good working condition, you need to conduct a thorough routine of maintenance and cleaning on regular basis. For this, below tips will be helpful:

Lubrication of movable part- Picture Courtesy: micro-lube.com

Cleaning:Cleaning is inevitable for maintaining ampoule machine. So, make sure to clean the machine each time when you are done with your daily task of ampoule processing. For this, use recommended cleaning agent with nonacidic water. For external part, you it is better to use a damp cloth for wiping safety window and main frame etc. Cleaning helps in removing out the contaminants and disinfecting machine.

Setting:Each time before you start machine, set its parameters including fill volume, speed, and sealing temperature etc. For structural setting, adjust the parts of machine including the tightening of screws and placement of parts on their right place.

Inspection:Regularly inspect your ampoule machine for possible wear and tear of parts. It is not always necessary, that the damage of part will display noise, rather you need to examine it by yourself. Moreover, it is also important to keep checking the machine during operation for irregularities.

Parts Changeover:It is for sure, that at any point a part of your machine gets damaged which if not replaced timely can ruin the process and cause further damage to other parts. So, you should changeover such parts and keep the frequently used parts available in your inventory.

Lubrication:Lubrication is very important for keeping the movable parts of machine smooth running and avoiding friction. For this, you need add recommended grease or oil each week. While doing this, make sure to clean the old grease avoid over lubrication.

11.How To Troubleshoot An Ampoule Machine?

While operating an ampoule machine, you may find few errors are causing interruption. In such case, you only need to assess the key problem, identify the possible causes and take relevant action. In this way, the underlying tips can be helpful to troubleshoot these errors:

| Filling inconsistencies | ||

Inconsistently filled ampoules- Picture Courtesy: Babor |

Cause:

The integrated filling tools are poorly calibrated. Filling nozzles are damaged. False setting of fill volume. The nozzles may be blocked causing inconsistent flow of liquids. |

Solution:

Calibrate the filling devices tightly. Replace the damaged sealing rings or adjust the filling nozzles. Reset the fill volume and speed of the machine. Clean the nozzles and remove out debris. |

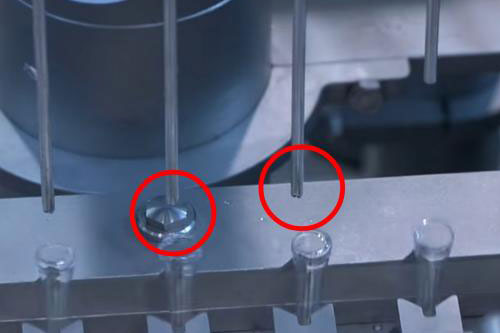

| Foaming and dripping | ||

Encircled filling nozzles |

Cause:

The filling system used is unsuitable for liquid. The sealing of nozzles may be damaged. Nozzles are out of order. |

Solution:

Use diving nozzles, so, that the foamy liquid will be settled. Tight the sealing ring inside filling nozzles. Replace the nozzles. |

| Ampoules breaking during operation | ||

Broken ampoule- Picture Courtesy: novalerm.com |

Cause:

The ampoules used are of poor quality. Excessive tension during filling and sealing may break the ampoules. The contact parts may be roughly handling ampoules. |

Solution:

Use high quality ampoules. Reduce the tension to avoid breakage. Make sure all the parts in contact with ampoules are smooth. |

| Defective sealing of ampoules | ||

Defected ampoules- Picture Courtesy: octum.de |

Cause:

The intensity of flame is excessive. Wrongly positioned ampoules may cause their deformation during sealing. |

Solution:

Reduce the temperature level by decreasing the intensity of flame. Adjust the tooling responsible for holding ampoules during sealing to ensure uniformity in shape. |

| Poorly sealed ampoules | ||

Highlighted poorly sealed ampoule- Picture Courtesy: sciencemadness.org |

Cause:

The flame intensity is low. Sealing time is insufficient. Nonaligned ampoules and sealing burn fire heads. |

Solution:

Increase the flame intensity. Increase the sealing time. Properly align the ampoules to that of sealing heads. |

12.Factors Essential To Consider For Buying An Indeal Ampoule Machine?

When buying an ampoule machine, it is essential to consider certain important factors in order to make a sound purchase. For this you should consider the underlying mentioned tips:

Production Capacity

Various glass ampoule- Picture Courtesy: syntegon.com

The first thing you need to consider is to determine the production capacity which you are aspiring. For instance, you are required to check your current production volume. It will simply help you in identifying whether you are in need of semi-automatic ampoule machine with small footprint or requiring fully automatic machine for large scale production.

Machine Features

AIPAK ENGINEERING- Features of an ampoule machine

Second important factor is to examine the features of machine which vary from one type of machine to another. For example, the type of filling system, the availability of pre and post nitrogen flushing, and ribbon wrapping around head etc. It will help you choose the most desirable machine.

Price

Dollar tag- Picture Courtesy: fool.com

Another aspect which should be paid heed is the evaluation of overall cost machine along with its maintenance, parts changeover, and operation cost. So, choose the machine that is within your budget while meeting your specific needs in the industry.

Vendor Reputation

Last but the most important factor you should look for is the vendor reputation. You can simply know it by checking the presence of supplier on several platforms like LinkedIn, google, and Facebook etc. along with feedback. Similarly, it is best to know their experience in supplying relevant machines. Moreover, considering the warranty policy and certification achieved can further help you in this way.

Conclusion

To put in a nutshell, Ampoule Machine: A Complete FAQ Guide In 2025, aims at enlightening you about its far-reaching benefits which can elevate your business. It is the ever-rapid advancements of technology that today we can have the sophisticated equipment like ampoule machine which is able to process eclectic ampoules with wonderful specifications. The sterility and hygiene of most sensitive liquids like drugs can now be simply achieved by employing this innovative machine. So, if you are planning to incorporate it in your business, don't forget to consider AIPAK ENGINEERING- a master in supplying ampoule machines. Feel free to contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours