8 Head ampoule Filling Machine: The Complete FAQ Guide In 2025

Are you looking for an ampoule filling machine with medium to large batch sizes? 8 head ampoule filling machines can do this job flexibly! How? The machine is designed with high-speed ampoule filling heads that can produce the desired results in a very limited time. If you’re thinking that it would be very expensive and require high expertise to run the equipment, then don’t worry. It is not what confuses you.

This machine is simple to operate and a time investment that can give you skyrocketing profit. For this reason, we have designed the 8 Head Ampoule Filling Machine: The Complete FAQ Guide In 2025. Read it to find technical answers to the essential questions related to the 8 head ampoule filling machine.

1.What is 8 head ampoule filling machine?

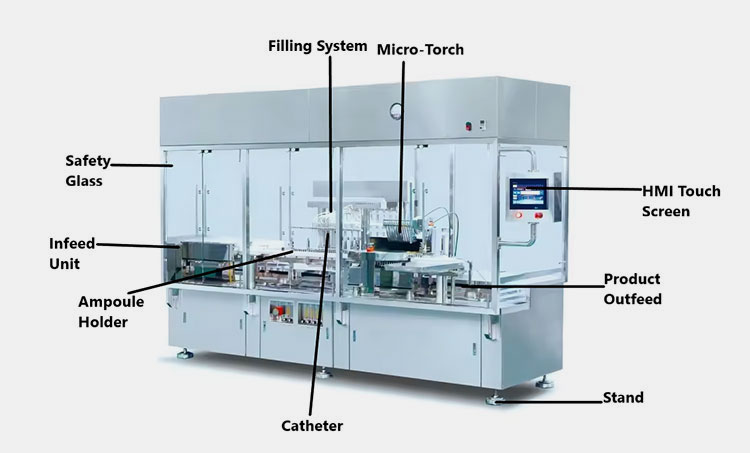

AIPAK ENGINEERING 8 Head Ampoule Filling Machine

It is technically referred to as a high-speed ampoule. It is an advanced-level machine, consisting of 8 filling heads, and highly effective in filling large quantities of ampoules. It can dose up to 8 ampoules at a time. It is suitable for medium and large-scale productions. It facilitates the packaging of glass capillaries by the pump-piston systems.

8 head ampoule filling machine is desired in industries because it is only not involved in the filling but also performs sealing and nitrogen flushing of ampoules. The sealing process is performed by micro-torches or flames that melt and seal ampoules.

It hygienically and smoothly processes a diverse range of batches to fulfill the demands of the medical and pharmaceutical sectors.

2.Where does 8 head ampoule filling machine show market applications?

8 head ampoule filling machine is a renowned technology and has proven its worth in different market applications. It is utilized in different manufacturing sectors to fill and seal different types of preparations. Below, we are presenting different areas of application of 8 head ampoule filling machine:

Pharmaceutical Industry

Pharmaceutical Ampoules- Picture Courtesy: Making

The pharmaceutical industry manufactures both solid and liquid dosage formulations. The parenteral preparations are mainly available in liquid form and filled and sealed in small-capacity containers, especially ampoules. In the pharmaceutical industry, 8 head ampoule filling machine is added for filling single quantities of painkillers, vaccines, cancer drugs, and anti-allergy medications.

Research and Development

Research and Development- Picture Courtesy: SCHOTT

Ampoules are excellent containers for accommodating a diverse range of un-tested and tested research samples. These containers provide stability to liquid preparations and keep them safe to carry out estimation studies, clinical trials, and other analytical studies. So, 8 head ampoule filling machine is a vital device in the research facilities to execute smooth ampoule packaging without disrupting the procedure flow.

Nutraceutical Industry

Nutraceutical Ampoules- Picture Courtesy: Lifestyle Asia

The nutraceutical industry is continuously evolving and is present halfway between the food and pharmaceutical sectors. It chiefly encompasses enriched food, liquid formulation, and solid dosages. Some nutraceuticals are probiotics, unsaturated fats, antioxidants, and vitamins.

The liquid nutraceutical formulations are ideally stored in the ampoules by the 8 head ampoule filling machine. This improves medication quality and allows you to acquire a healthy life.

Cosmetic Industry

Cosmetic Ampoules- Picture Courtesy: Skincare

Ampoules are gaining popularity in the cosmetic industry for loading and sealing various cosmetic preparations like skin whitening serums, primers, age-repairing solutions, skin remedy formulas, collagen-stimulating treatments, hyaluronic acids, and many others. Therefore, 8 head ampoule filling machine is a pivotal part of the cosmetic industry for packing cosmetic goods, which ensures their potency.

Veterinary Industry

Veterinary Ampoules- Picture Courtesy: Animal Medical Sector

Because of the evolution of the veterinary industry, nowadays, special medications are formulated for pets such as insecticidal treatment, analgesics, gastro remedies, antibiotics, vaccines, and anti-allergy, to name a few. Hence, for the perfect packaging of pet medications, the 8 head ampoule filling machine has a significant role in the veterinary industry. This facilitates faster production and management of dosing systems.

Chemical Industry

Chemical Ampoules- Picture Courtesy: Reagent UK

The chemical industry typically processes a wide range of agro-insecticides, pesticides, research-related chemicals, acids, alkalis, raw products, and organic and inorganic liquids. These chemicals are dosed in the ampoules by the 8 head ampoule filling machine for their preservation and storage purposes.

3.How 8 head ampoule filling machine is profitable to your business?

The latest generation of 8 head ampoule filling machine gently processes different ranges of ampoules. Hygienic handling is the mainstay of such machines, thus thwarting contamination. Several other benefits that make 8 head ampoule filling machine extremely profitable to your business, are detailed below:

Large Processing Output

Large Processing Output- Picture Courtesy: Dalton-Cosmetics

The 8 head ampoule filling machine is furnished with different parts that act in synchronization to allow completion of filling, sealing, and cutting steps in one cycle. Thus, with this machine, you can achieve large processing rates and pack a higher number of products in a short time. It is routinely found in sophisticated industries to meet production goals.

Accurate Amount of Medication

Accurate Amount of Medication- Picture Courtesy: SCOTT-Pharma

Accuracy of volume is integral in attaining dose accuracy. This accuracy is essential in keeping the health of patients safe. Hence, pharmaceutical manufacturers prefer to install highly precise machines, and 8 head ampoule filling machine is no different.

It is an exceedingly trailblazing instrument that allows manufacturers to attain precision in filling therapeutics and delivering the doses that are needed.

Extension of Shelf-life

Extension of Shelf-life- Picture Courtesy: Dynasty

It is a well-known fact that 8 head ampoule filling machine is equipped with micro-torches that enable the melting of glass, guaranteeing an effective seal. Therefore, there is no need to worry about contamination of products by physical, chemical, and biological chemicals. The ampoules are purged with nitrogen both before and after filling in 8 head ampoule filling machine, which prevents the progression of microbes, consequently extending the shelf life of medications.

Increased Aesthetic Appeal

Increased Aesthetic Appeal- Picture Courtesy: Vial Labeller

The 8 head ampoule filling machine is synonymous with the sleek and professional sealing of ampoules. This remarkable ampoule appearance boosts the customer's trust and confidence in the quality of medication. Certainly, it is an unfailing way to fulfill fabrication objectives with superior-quality sealing.

Saves Money

Saves Money- Picture Courtesy: Dalton Cosmetics

Undoubtedly, a system with high-level sensors and the latest filling and sealing components performs each step flawlessly and without any difficulty. Then, why seek extra labor? So, 8 head ampoule filling machine is a system that minimizes entire labor costs and improves operational cost-effectivity.

4.How is the 8 head ampoule filling machine designed?

Indeed, 8 head ampoule filling machine is a complex system with various specialized parts. It has a compact design construction with several ampoule processing parts for continuous ampoule filling and sealing. For your learning, we are penning fundamental parts of the 8 head ampoule filling machine.

Parts of 8 Head Ampoule Filling Machine

| Filling System | It is the core unit in the equipment, consisting of filing catheters, valve regulators, pumps, and ampoule holders. This area is involved in the product dosing. |

| Safety Glass | The operational area of the 8 head ampoule filling machine is sealed by the safety glass to reduce the chances of product contamination and allow operators to visualize the working of the machine. |

| Infeed Unit | The empty ampoules are fed inside the 8 head ampoule filling machine by the efficient movement of the conveyor and turntable. The infeed unit is needed for introducing the ampoules inside the equipment. Its speed can be controlled by changing batch capacity. |

| Ampoule Holder | These components are integral in keeping the ampoules firmly in place during the filling and sealing process. It reduces the risk of ampoule falling and breakage. |

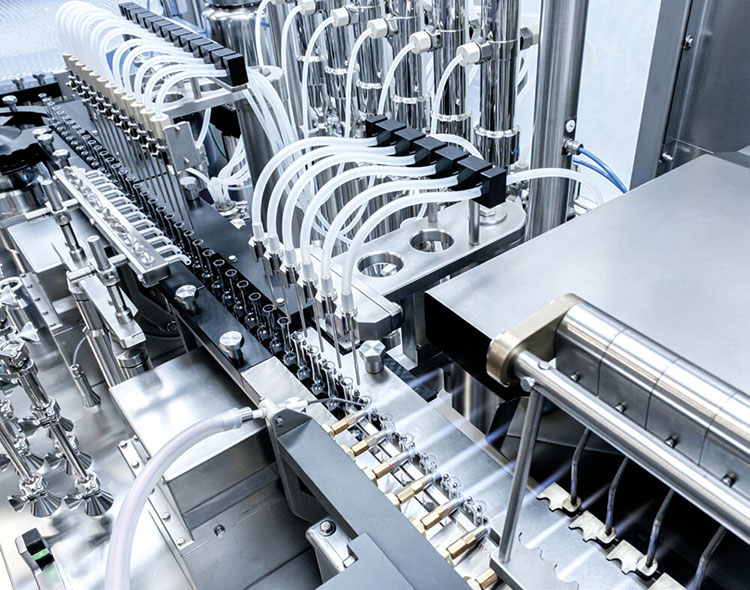

| Catheter | It is a tiny microscopic needle that deposits the formulation into the ampoules accurately. With its tiny aperture, there is less chance of preparation exposure to the environment. It is positioned with the opening of the ampoule to prevent spilling and wastage. |

| Stand | This component forms the base of 8 head ampoule filling machine and is responsible for stabilizing and supporting the weight of instrumentation. |

| Product Outfeed Unit | Its function is to transport and remove the finished ampoules outside of equipment. The product outfeed unit is also equipped with a turntable and conveyors for transferring the ampoules. |

| HMI Touch Screen | It is a high-tech part, in charge of regulating parameters, controlling machines, diagnosis, and troubleshooting. It is a link between the operator and the equipment. This intuitive touch screen helps in managing the functionalities of different machine parts with the programming of settings. |

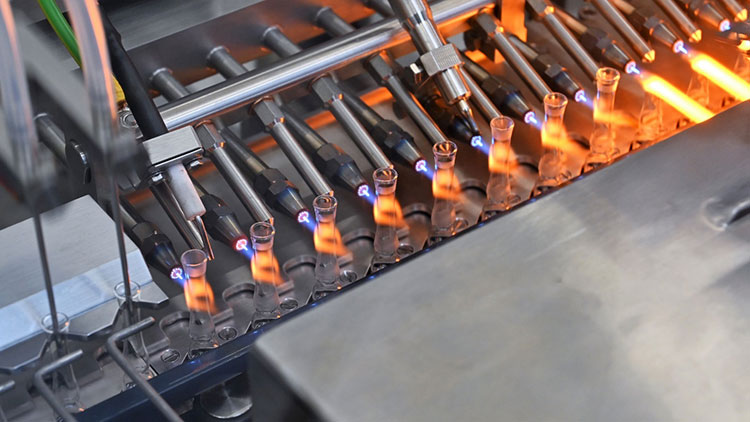

| Micro-Torch | It is a set of flames, also called micro-torch, and emits fire to melt the ampoule layer. This melting results in shaping and securing the product. Mirco-torch creates a hermetic seal for the safety of materials. |

5.How can 8 head ampoule filling machine work?

The 8 head ampoule filling machine has a complicated working principle, involving a series of steps like filling, sealing, cooling, and unloading. These steps are seamlessly executed to manufacture large batches of ampoules. Here is a complete list of working steps occurring in the 8 head ampoule filling machine:

Loading of Glass Capillaries

Loading of Glass Capillaries- Picture Courtesy: SCHOTT

A designed turntable or conveyor system in the 8 head ampoule filling machine is devised to load the tiny glass capillaries or empty ampoules into the packaging instrumentation.

Pre-Nitrogen Flushing

Pre-Nitrogen Flushing- Picture Courtesy: Steriline

Before the filling process, pre-nitrogen flushing is performed. In this process, nitrogen is introduced in the empty ampoules for aseptic processing.

Filling of Ampoules

Filling of Ampoules- Picture Courtesy: ROTA

In this step, the catheters or micro-pipettes of the filling unit are positioned into the empty ampoules. This positioning helps ease product fluidity in the ampoules. It draws products very accurately and delicately in ampoules.

Post-Nitrogen Flushing

Post-Nitrogen Flushing- Picture Courtesy: Harikrushna

After the product filling but before the sealing process, nitrogen flushing is again carried out. Nitrogen is fed into the headspace of the filled ampoules. This process is significant from a sterility perspective.

Sealing

Sealing of Ampoules- Picture Courtesy: Concept Automation

Immediately after post-nitrogen flushing, gas capillaries are sealed, trapping nitrogen inside the ampoules. Several micro-torches are integrated into the 8 head ampoule filling machine, for blowing hot flames on the glass of filled ampoules delicately. This brushed fire track is necessary for melting the layer of glass. This molten glass is fused and sealed hermetically.

After the sealing, now ampoules are ready to discharge to next-in-line inspection and labeling machines for evaluation and information labeling, respectively.

6.What is the production line of 8 head ampoule filling machine?

Various machines are integrated with the 8 head ampoule filling machine to bring out step-by-step processing. Ampoule packaging is a multi-stage approach, where each stage is carried out and completed by different equipment. Below is the complete guide to the production line of 8 head ampoule filling machine:

Ampoule Washing and Cleaning Unit

AIPAK ENGINEERING Ampoule Washing and Cleaning Unit

It is the starting instrumentation in the production line and its importance cannot be ignored because, in this unit, glass capillaries are washed and rinsed using different cleaning agents. Detergent and water clean the less sticky residues, while high-frequency ultrasonic waves are hit on the walls of glass capillaries to ensure the removal of hard-to-remove particles and fragments.

Ampoule Sterilization and Drying Unit

AIPAK ENGINEERING Ampoule Sterilization and Drying Unit

For achieving a high rate of sterility and dryness of ampoules, the best machine is the ampoule sterilization and drying unit. This equipment is equipped with hot laminar air flow that not only helps in the evaporation of excess moisture from the ampoules but also ascertains the absence of pyrogen in the ampoules.

Glass ampoules are uniformly heated to avoid the explosion of ampoules. A water circulation system is also present in this unit for cooling ampoules.

8 Head Ampoule Filling Machine

8 Head Ampoule Filling Machine- Picture Courtesy: IVEN Pharma

Ampoules are transferred to the 8 head ampoule filling machine for dosing of liquid and powdery preparation and then, are subsequently sealed by micro-torches. It is offered with no ampoule no filling sensor that avoids the wastage of medicinal formulation.

Ampoule Inspection Unit

Ampoule Inspection Unit- Picture Courtesy: SED Pharma

It is important to package parenteral formulation, ensuring the absolute safety of patients. Hence, the ampoule inspection unit has a fundamental place in the production line of ampoule packaging. It is added soon after the 8 head ampoule filling machine.

It boosts the quality of packaged ampoules by identifying superficial and internal defects in the ampoules, for instance, breakage or unwanted contaminants in medications.

It adopts photoelectric cameras and image analysis software for detecting flaws. It works consistently to discard low-quality products.

Ampoule Labeling Unit

AIPAK Ampoule Labeling Unit

Labeling is needed to inform patients and health caregivers about the name and expiry date of the product, brand facts, and volume of the formulation. Once excellent-quality ampoules are approved by the ampoule inspection unit, the ampoule labeling unit comes into play.

It applies mandatory labels on ampoules using label presses and thermal transfer printers.

7.What materials can 8 head ampoule filling machine operate?

Glass Ampoules- Picture Courtesy: Carl Roth

Generally, the 8 head ampoule filling machine is manufactured to operate with glass materials. The sealing process of ampoules is performed at high temperatures and pressure, thus it is pivotal that ampoule materials must withstand this harsh environment.

So, glass has a significant value in pharmaceutical manufacturing, as it can tolerate such extreme changes without breaking. Glass is typically created from borosilicate and soda lime. These glass ampoules are 100% tamper-safe and have superior chemical resistance. It is suitable for storing products that require stable pH.

Moreover, glass is a preferred material for ampoules because of its excellent leachable profile. It is heat-sterilized to remove microbial contaminants. Glass ampoules do not interact with the inner formulation. It offers light protection and is easily recyclable, thus increasing the sustainability of ampoules.

8.What volume range 8 head ampoule filling machine can fill?

Volume of Ampoules- Picture Courtesy: Clear Skin House

The volume range of the 8 head ampoule filling machine normally depends upon the machine design, model, and configuration. The minimum and maximum volume of the dose in the ampoule characteristically depends on the size, design, and working capacity of the filling pumps, piston cylinders, and filling heads or catheters.

Also, the dimensions of ampoules limit the highest volume in the ampoules. Some types of 8 head ampoule filling machines are capable of packaging small doses of about 0.5 to 10 ml, whereas, other heavy-duty machines with large-capacity filling systems can process higher doses of up to 30 ml.

8 head ampoule filling machine is flexible in its volume range and can dose small volumes of specialized preparation or drugs for clinical trials. Moreover, it can easily manage large volumes of commercial medications.

9.What is the role of pre and post-nitrogen flushing in 8 head ampoule filling machine?

Pre and Post-Nitrogen Flushing in 8 Head Ampoule Filling Machine- Picture Courtesy; IVEN Pharma

The sterility of pharmaceutical and medical products is the principal aspect of guaranteeing patient safety. Without absolute purifying of drugs, the health of patients is compromised. Therefore, several steps are implemented in the manufacturing industry to ensure sterility, with one being pre and post-nitrogen flushing.

Nitrogen is a non-reactive gas, used for blanketing and purging. Pre-nitrogen flushing substitutes the oxygen in glass capillaries. Oxygen deteriorates sensitive medications like injectables by oxidation of compounds. Thus, with pre-nitrogen flushing, this hazard is prevented.

Moreover, it creates a protective environment by preventing the development of microbes, consequently averting contamination. This step also minimizes the condensation risk inside the ampoules.

Post-nitrogen flushing ensures the elimination of residual oxygen after product filling. It foils oxidation of liquids during the sealing step, upholds product integrity, and prolongs its expiration date.

10.What gases are used for sealing ampoules in 8 head ampoule filling machine?

Sealing of Ampoules- Picture Courtesy: ROTA

The sealing of ampoules is a critical step that validates the purity of ampoules. This step is accomplished with the use of flames. These micro-torches are lit by oxygen and other combustible gases such as propane.

This gas flame technique is utilized in the traditional 8 head ampoule filling machine. These gases aid in ampoule melting during preheating and sealing steps. Oxygen is utilized during the sealing process to support the burning of flames, while natural gases fuel the torch.

11.How to clean and maintain an 8 head ampoule filling machine?

Cleaning and Maintenance of 8 Head Ampoule Filling Machine- Picture Courtesy: Concept Group LLC

Cleaning and maintenance are significant aspects of the operational life of 8 head ampoule filling machine. The quality of products, zero contamination, and durability of the machine are dependent upon cleaning and maintenance procedures.

They ensure the machine's compliance with regulatory protocols. So, we are presenting principal cleaning and maintenance tips for the 8 head ampoule filling machine.

Cleaning

First of all, disassemble the equipment into different parts like removing filling heads, sealing devices, and other critical components.

Use pharmaceutical equipment-approved cleaning agent for cleaning machine. It is recommended to avoid harsh cleaning agents, as they can deteriorate parts.

Wash and rinse all detachable parts with the cleaning agents. Soft brushes and cloths could be used for removing product residues. Use an autoclave and chemicals for sterilization of parts. Stubborn debris is usually removed by ultrasonic waves.

Wipe down the external areas of the machine with a wet cloth. Use approved disinfectant to sanitize the internal surface of the device.

Dry every part before reattaching to prevent part damage. Then, reassemble the parts according to the manufacturer's instructions.

Maintenance

Daily inspect the machine for evident wear, leak, or deterioration. Once a week, conduct a detailed inspection for checking loose screws, part misalignment, and misplacement of safety guards.

Lubricate moving components using approved lubricants as per manufacturer recommendation.

Regularly calibrate filling catheters and other sensors to ascertain fill volume accuracy.

Maintain inventory of recurrently wearable parts like seals, gaskets, etc, and replace them when needed.

Update the firmware to avoid occasional bugs and errors in machine operation.

12.What are the common technical problems related to the 8 head ampoule filling machine?

8 head ampoule filling machine is sophisticated equipment that runs smoothly most of the time. However, there comes a time when it encounters an occasional technical problem that affects its operational efficiency. Therefore, here is the list of common technical problems and their solutions:

Inaccurate Filling Volumes

Inaccurate Fill Volume- Picture Courtesy: ROTA

Cause

When the filling heads are not calibrated properly or there is damage in the dosing pumps, this problem can occur. Moreover, blockage in the liquid flow devices can be the reason for this problem.

Solution

It is advised to follow the proper cleaning schedule, especially for the filling heads and fluid pathways. Furthermore, replacing dosing system components can resolve this problem.

Misalign Ampoule Holders

Misalign Ampoule Holders- Picture Courtesy: Pharma Manager

Cause

With time, the parts of the 8 head ampoule filling machine, particularly ampoule holders get damaged because of mechanical stress and inappropriate handling.

Solution

This problem can be resolved by inspecting and readjusting the orientation of ampoule holders so that ampoules are accurately arranged under the filling heads.

Ampoule Breakage

Ampoule Breakage- Picture Courtesy: Silicon Republic

Cause

It can happen when machine parts are not properly positioned and there is high filling pressure. Also, damaged and low-quality ampoules can result in ampoule breakage.

Solution

To solve this issue, properly realign the machine parts and regulate the filling pressure. It is also recommended to check the ampoules for defects before dosing.

Partial Seal

Partial Seal- Picture Courtesy: Heat Sense Cables

Cause

There are several reasons for this problem, for instance, low flame force, short sealing duration, and misalignment of glass capillaries with the micro-torch.

Solution

It is suggested to control and boost the flame intensity and to upsurge the sealing exposure time. Moreover, proper adjustment of ampoules with a sealing torch can solve this issue.

13.What is the prospect of an 8 head ampoule filling machine?

Future of 8 Head Ampoule Filling Machine- Picture Courtesy: IVEN

The future of 8 head ampoule filling machine is shaped by technological innovation, changes in industrial requirements, and worldwide health trends. Let’s take a look at the potential future of this device:

In the future, the 8 head ampoule filling machine will be manufactured with advanced automated tools, including Industry 4 technology, for example, the Internet of Things, artificial intelligence, and machine learning. These technologies will boost the immaculate information exchange, machine diagnosis, and smooth production flow. Moreover, this will allow real-time inspection and increase the efficiency of instrumentation.

Futuristic 8 head ampoule filling machines might have modular designs, leading to the adaption of machines to new formulations and processing of diverse product batches. This device may integrate energy-conservation processes and have minimal material waste. It may incorporate advanced sterilization protocols for handling various injectables and biopharmaceuticals.

Conclusion

Dosing of ampoules is a daunting task that requires critical handling and sterile processing. Unquestionably, 8 head ampoule filling machine is the best machine for this job. This machine is customized to fulfill the demands of growing markets with its ever-efficient parts. It is a high-grade instrument that is offered with fire brushes, filling catheters, and other units to seamlessly support a functioning workflow. If you require sterile and tailored 8 head ampoule filling machines, we, AIPAK ENGINEERING, are more than ready to provide you with superior-quality machinery. So, get ready to discuss your options with us to acquire the latest solutions.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours