Ampoule Filling and Sealing Machine: The Complete FAQ Guide In 2025

Why ampoules are gaining traction in healthcare and pharmaceuticals?

This question puzzles in almost everyone’s mind. Well, it is because ampoules have single-dose servings and are convenient to use. But how ampoules are filled and sealed?

The answer is by ampoule filling and sealing machine. This machine is a game-changer for pharmaceutical and medical manufacturing. Its ability to produce coherent results within a short span is what makes this machine popular in industries.

We have designed a special blog post just for you, and different manufacturers out there. We would like you to read this blog on "Ampoule Filling and Sealing Machine: The Complete FAQ Guide in 2025" to make use of the handy knowledge penned in this blog. Come along for a knowledgeable trip.

1.How to Define Ampoule Filling and Sealing Machine?

Ampoule Filling and Sealing Machine- Picture Courtesy: Syntegon

An ampoule filling and sealing machine is a specialized unit for filling and sealing ampoules. In this machine, different processes like loading ampoules with liquids, gas purging, and sealing them with flames are involved.

This machine has varying levels of automation and has extreme flexibility and reliability that streamline whole production. It ensures the gentle processing of ampoules and their hygienic packaging. The ampoule filling and sealing machine easily processes both small and large batches.

2.Why are the Ampoule Filling and Sealing Machine Significant in Industries?

An ampoule filling and sealing machine is hugely beneficial in industries because of its no-fill error and complete sterility. It is a great addition to the field of healthcare and pharmaceutical field due to its countless benefits; some of which are listed below:

Stability for Extended Period

Stability for Long Period- Picture Courtesy: sweetcare

An ampoule filling and sealing machine provides guaranteed stability to a filled ampoule for a long time because of its nitrogen purging feature. This allows businesses to remove oxygen and substitute it with nitrogen gas. Thus, the product will have a longer expiration date due to its ability to withstand the progression of microbes.

Extremely User-friendly

User-Friendliness- Picture Courtesy: Boutique Skin Envie

The ampoule filling and sealing machine is extremely user-friendly equipment. This machine is adorned with advanced technology like a touch screen and PLC control panels. These high-tech gadgets are easier to use and require little to no specialized skill.

Once you familiarize yourself with different parts and set points, you can easily run this machine stand-alone.

Fill Volume Accuracy

Fill Volume Accuracy- Picture Courtesy: Marnys

With an ampoule filling and sealing machine, there is failsafe fill volume accuracy because it fills the exact volume of medication in every batch. The presence of computerized and extremely accurate sensors allows it to measure and dispense specific injectible quantities every time. Dose accuracy is the renowned feature of the ampoule filling and sealing machine.

Saves Money

Saves Money- Picture Courtesy: Lutz Packaging Gmbh

With extremely efficient sensors and state-of-the-art automation levels in an ampoule filling and sealing machine, you can save money. This machine is a completely autonomous unit, saving significant operator wages by cutting down labor requirements.

Boost Productivity

Boosts Productivity- Picture Courtesy: Stevanato Group

It is a tremendously efficient solution, filling thousands of ampoules per minute. It boosts the productivity of the business. More productivity means more products in the market, which translates into a higher profit margin. Thus, there is no need for conventional and manual filling methods with the ampoule filling and sealing machine.

3.In What Industries the Ampoule Filling and Sealing Machine is Found?

The industrial applications of an ampoule filling and sealing machine are vast and unlimited. This machine is employed in different industrial lines for the manufacturing of different kinds of medicinal liquids. Let’s explore various uses of the ampoule filling and sealing machine.

Pharmaceutical Industry

Use of Ampoule Filling and Sealing Machine in Pharmaceutical Industry- Picture Courtesy: ReAgent

In the pharmaceutical industry, the ampoule filling and sealing machine is utilized for loading single doses of vaccines, painkillers, antibiotics, chemotherapy, and other related drugs. This machine has a significant role in the pharmaceutical industry for sterile processing of different therapeutic solutions.

Biotechnology Industry

Use of Ampoule Filling and Sealing Machine in Biotechnology Industry- Picture Courtesy: European Pharmaceutical Manufacturer

Ampoule filling and sealing machine is crucial in the biotechnology industry because it dispenses accurate dosing of valuable substances like insulin and other recombinant proteins, antibodies, cell culture, and plasma. It also aseptically fills different types of gene therapy agents and vaccinations in neat and sophisticated ampoules.

Diagnostic Industry

Use of Ampoule Filling and Sealing Machine in Diagnostic Industry- Picture Courtesy: AntiTeck

Various types of diagnostic reagents, diagnostic kits, control solutions, sample preparation, and buffer solutions are handled and processed in the diagnostic industry. Therefore, the ampoule filling and sealing machine is needed by the diagnostic industry for accurately dosing and sealing of diagnostic agents in the ampoules.

Cosmetic Industry

Use of Ampoule Filling and Sealing Machine in Cosmetic Industry- Picture Courtesy: Greenleaf Cosmetics

Yes, you are reading it right. The ampoule filling and sealing machine is also essential in the cosmetic industry. It precisely loads one-time-use quantities of cosmetic preparations like serums, essential oils, skin fillers, skin products, and other beauty liquids into the ampoules. This machine is integral in consistent packaging and upholds the product integrity in the cosmetic line.

Chemical Industry

Use of an Ampoule Filling and Sealing Machine in the Chemical Industry

It is difficult to safely deal with potent chemicals; however, this matter is of no concern with the ampoule filling and sealing machine. It allows the packaging of specialty and laboratory chemicals, and analytics solutions in the single-use ampoules. It safely packages hazardous chemicals and ensures precise measurement.

Veterinary Industry

Use of Ampoule Filling and Sealing Machine in Veterinary Industry- Picture Courtesy:

Neftis Laboratorios

The ampoule filling and sealing machine is also utilized in the veterinary industry for filling of different vet injectables, vaccines, and nutritional supplements. There is no contamination with this machine and it ascertains the correct dosing of animal therapies.

4.Enumerate the Step-by-Step Working of the Ampoule Filling and Sealing Machine.

There are several steps involved in the working of an ampoule filling and sealing machine. Each step has a specific part in the smooth and precise dosing of ampoules. Let’s have an insight into the working of the ampoule filling and sealing machine.

| Ampoule Feeding

To maintain a smooth and steady supply of ampoules in the machine, they are loaded manually or automatically on the conveyors. The ampoules are fed from the hopper to the conveyor system of the machine. |

Picture Courtesy: MedicalExpo |

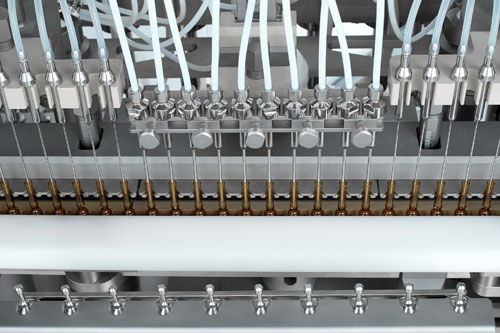

| Filling

In this step, different types of nozzles and pumps precisely load the required volume of injectable solution into the ampoules. Sensors are ever ready during this step to detect any abnormalities. |

Picture Courtesy: IMA Group |

| Post-gassing

Inert gas or nitrogen purging occurs at this step. This is done to flush out oxygen from the containers and to increase the sterility of the filled ampoules. |

Picture Courtesy: IVEN Pharmatech |

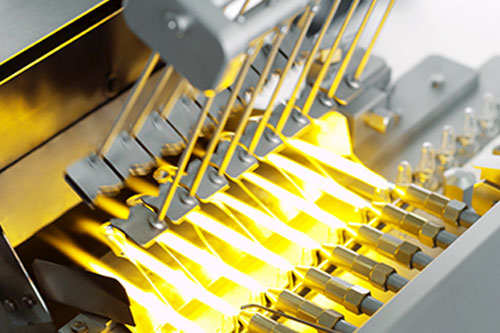

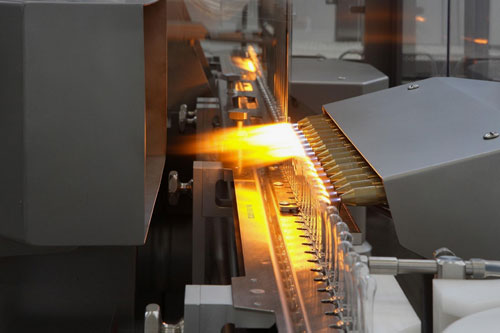

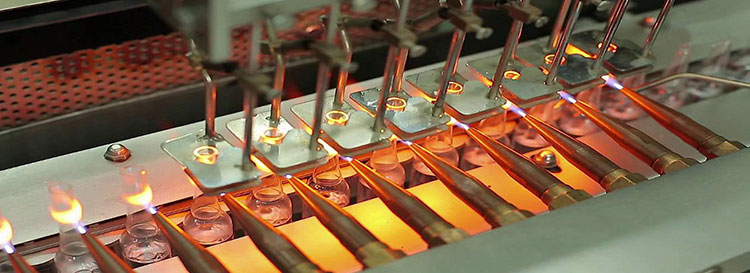

| Pre-heating

The ampoules after gas purging are transferred to the pre-heating unit. In this unit, flame is utilized to melt the glass of ampoules. It ensures the correct shape of ampoules. |

Picture Courtesy: SSBO |

| Sealing

Fire melts and seals the layer of glass and creates a tamper-evident seal. The brush fire is important in sealing the opening of the ampoules by their melting and fusing. This fire creates aesthetically pleasing ampoules. |

Picture Courtesy: Marchesini Group |

5.What Parts Constitute Ampoule Filling and Sealing Machine?

The parts in the ampoule filling and sealing machine make it a specialized unit. To bring about precise injection, each component in this handy unit has an important contribution. Here is a list of parts constituted in the ampoule filling and sealing machine.

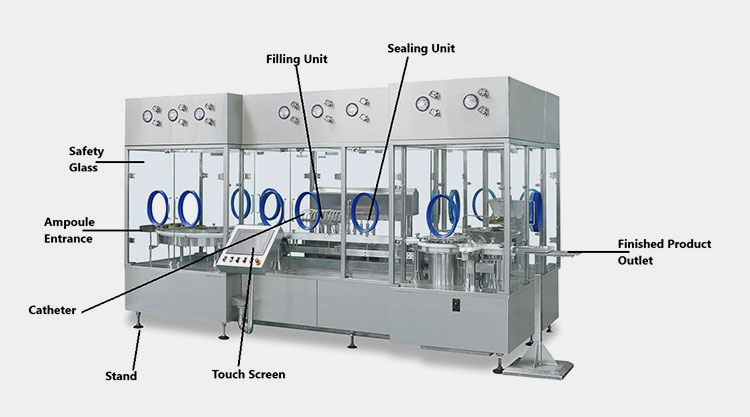

Parts of Ampoule Filling and Sealing Machine

Safety Glass

To safely monitor the progress of the ampoule filling and sealing process, a glass safety door is utilized. This door is a safety feature that decreases the exposure of the operator to the machine while the latter is filling and sealing.

Ampoule Entrance

The ampoules are loaded at the machine entrance by the operator or by the ampoule-feeding machine. Then conveyor systems carry them towards the filling station.

Filling Unit

It is the main area where ampoules are loaded with different types of injectable solutions. The filling unit consists of catheters and different types of pumps. The pump system aids in the circulation and fluidity of different therapeutic preparations.

Catheter

It is a fine needle-like component and its job is to feed the liquid preparation into the ampule. Its main goal is to dispense precise dosing solutions without causing wastage.

Sealing Unit

This zone has a burner that radiates flame to melt and soften the ampoule structure. This burner is called a brushed fire head and is responsible for hermetically sealing the ampoule. The molten glass is joined at the sealing station to create a proper sealing structure of ampoules. Different types of regulators are also present in the sealing station that control the placement and temperature of the brush fire head.

Stand

This forms the base of the ampoule filling and sealing machine. It is responsible for providing the stability to the machine.

Touch Screen

It is a high-tech gadget that has clearly labeled options for programming the machine. Monitoring, supervision, diagnosis, and troubleshooting of the machine are carried out by a sensitive and intuitive touch screen.

Finished Product Outlet

The steady motion of conveyors aids in transporting filled and sealed ampoules outside of the machine via the finished product outlet. These products are transferred to the collection bin and then moved to further processing steps.

6.What are the Filling Methods in Ampoule Filling and Sealing Machine?

Filling Methods in Ampoule Filling and Sealing Machine-Picture Courtesy: Manufacturing Chemist

The ampoule filling and sealing machine uses different filling methods to fulfill the liquid filling demands of different industries. Here are the basic filling methods employed by the ampoule filling and sealing machine.

| Vacuum Filling | This type of filling is done in a closed system and utilizes the vacuum for drawing liquids in the ampoules. There is no contamination in vacuum filling. Moreover, it results in precise filling. |

| Pressure Filling | It uses pressure forces to draw the injectable into the ampoules. It is fast and is used for loading high-viscosity liquids. |

| Volumetric Filling | This kind of filling is vastly utilized for filling ampoules. It loads a pre-measured quantity of liquids. The pump and piston are used in volumetric filling. |

7.Enlist Sealing Methods for the Ampoule Filling and Sealing Machine.

There are two main sealing methods in the ampoule filling and sealing machine. These sealing approaches are detailed one by one below:

Pull Sealing Approach

Pull Seal Method- Picture Courtesy: SFAM

The melting and sealing process occurs in the middle of the glass ampoule by the intense flame. In this sealing method, the elongation of a thin layer of glass ensues to create a strong seal, thus the name “pull sealing method”. This creates a thin neck of glass ampoules and a pointed seal. However, there are differences in the height of the glass ampoule by this sealing method. Moreover, the irregular-shaped neck of ampoules causes an increased chance of cutting.

Tip Sealing Approach

Tip Sealing Approach- Picture Courtesy: Pharmaceutical Online

It is also referred to as bead-seal method. In this approach, a high-temperature burner melts the neck of the glass ampoule at the top side, creating a smooth seal. This approach produces a round seal. This seal is aesthetically pleasing with no risk of cutting.

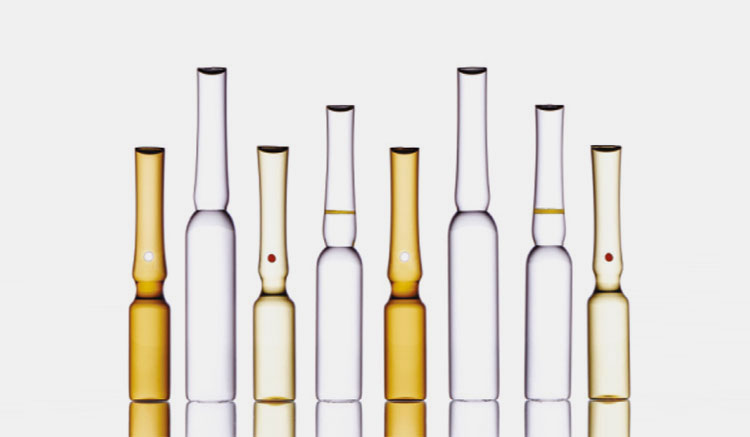

8.What Ampoules are Sealed by Ampoule Filling and Sealing Machine?

There are broad range of ampoules sealed by the ampoule filling and sealing machine such as:

Types of Ampoules Based on Material

Glass Ampoules

Glass Ampoules

They are manufactured using glass and are important in maintaining the sterility of the inner liquids due to their strong barrier properties. Furthermore, glass is an inert material and is resistant to chemical reactions and thermal shock.

Plastic Ampoules

Plastic Ampoules- Picture Courtesy: CDM Lavoisier

As the name refers, these tiny containers are manufactured using plastic and include twist-off ampoules. They are light in weight and are shatter-proof. Moreover, it is easier to squeeze plastic ampoules for pouring out the liquids.

Types of Ampoules Based on Shape

Form B Ampoules

Form B Ampoules- Picture Courtesy: Borosil Klasspack Limited

They have a cylindrical structure with a round base. It also features a straight neck, consequently, its design is referred to as a straight-stem shape. It is the latest innovation in the design of ampoules.

Form C Ampoules

Form C Ampoules- Picture Courtesy: medike pharmaceutical package

This type of ampoule has a funnel-like structure. It has a bulbous body and a wide, funnel-shaped neck rather than a straight neck of form B-type ampoules. It is the oldest type of ampoule and has greater height than form B ampoules.

Form D Ampoules

Form D Ampoules- Picture Courtesy: medike pharmaceutical package

They are also called closed-type ampoules and have a round body with a closed top. They do not require separate sealing because of their already sealed form. They are used for injectables that do not require aseptic filling. They pose a higher chance of contamination.

Types of Ampoules Based on Breakage

Pre-Scored Ampoules

Pre-Scored Ampoules- Picture Courtesy: Carl Roth

They have pre-scored lines around their neck. They allow easy and controlled breakage of the ampoules. Clean and precise breaks are possible with pre-scored ampoules.

Color Ring Ampoules

Color Ring Ampoules- Picture Courtesy: Lutz Packaging Gmbh

They have colored rings around entire their necks for convenience in breakage. These colored rings denote the breakage area of the ampoules.

One Point Cut Ampoules

One Point Cut Ampoules

They have a single scored point present around the neck. This pre-scored point allows ease in the breakage of the ampoules.

9.What are the Quality Certifications for the Ampoule Filling and Sealing Machine?

There are different quality certifications for the ampoule filling and sealing machine to determine its processing and material quality. Some quality certifications of this machine are listed below:

cGMP Certification

cGMP Certification

This is an important certification that is made compulsory by the FDA. It is the highest possible quality certification, necessary for machinery present in the pharmaceutical and food industries. Hygienic manufacturing and cleanliness are ensured by this certification.

FDA

FDA

FDA compliance is an integral part of quality documentation. This certification denotes the machinery meets the stringent safety and quality standards.

ISO

ISO

It is an internationally known quality standard. It denotes that the machine is made following the safety, quality, and, sterile standards. Moreover, it shows the manufacturer's commitment to consistently improve its manufacturing standards.

CE Marking

CE

Health, safety, and environmental protection guidelines are enforced by the CE marking. This certification denotes the ampoule filling and sealing machine is manufactured according to every guideline set by the European Union.

10.What are Some Tips to Resolve Basic Problems in the Ampoule Filling and Sealing Machine?

The ampoule filling and sealing machine is complicated machinery, where problems are part of routine operations. These problems severely impact the production flow and reduce the packaging outcome. Thus, a systematic approach is used to solve these issues in the ampoule filling and sealing machine. Here are some tips to resolve basic problems in this machine.

Inaccuracies in Filling

Inaccuracies in Filling- Picture Courtesy: Chinasun

Cause

Poor calibration of filling devices.

Filling nozzles are damaged.

Inconsistencies in the fill settings.

Blockage or leakage in the fill lines.

Solution

Check and calibrate the filling devices.

Repair the damaged filling nozzles.

Adjust the fill settings.

Inspect the blockage and leakage in the fill lines.

Ampoule Breaks During Filling and Sealing

Ampoule Breaks During Filling and Sealing- Picture Courtesy: Jinan Horizon

Cause

High pressure during the filling process.

Rough handling.

Ampoules are manufactured with poor-quality materials.

Solution

Decrease the pressure during the filling process.

Avoid rough handling during the filling and sealing process.

Use high-quality ampoules.

Deformed Ampoules

Deformed Ampoules- Picture Courtesy: heuft

Cause

High flame intensity.

Ampoules are not positioned properly, causing deformation.

Solution

Decrease the flame intensity.

Properly place ampoules on the sealing flames to ensure consistency in the shapes of ampoules.

Incomplete Sealing of Ampoules

Incomplete Sealing of Ampoules- Picture Courtesy: Aajjo

Cause

Decrease flame intensity.

Low duration of sealing time.

Ampoules are not aligned with the sealing head.

Solution

High the flame intensity to ensure a proper seal.

Increase the sealing time.

Properly align ampoules with sealing heads to ensure uniform sealing.

11.How to Select the Best Ampoule Filling and Sealing Machine for Business?

Buying the best quality equipment that fits your budget, increases uptime and leads to the timely completion of the project. However, it is a complex task, and buying from a reputable manufacturer matters the most. Therefore, we are offering some tips and tricks that should be considered for selecting a high-quality ampoule filling and sealing machine.

Budget Allocation

Budget Allocation- Picture Courtesy: Bank of Hawaii

The money in your hand forms a basis for selecting and evaluating the type of ampoule filling and sealing machine. If you have a limited budget then search for simple machinery that completes the ampoule filling and sealing machine. However, if you start with more budget then you can buy high-tech and fully automated equipment.

Production Requirement

Production Requirement- Picture Courtesy: Lodha International

The second thing to evaluate after budget is the production requirement of the business. The production requirement determines the level of automation and speed of the equipment. Large-scale productions usually go for high-speed ampoule filling and sealing machines.

Versatility

Versatility- Picture Courtesy: Política VcM UST

It is important to think about the versatility of equipment when you go out to purchase the ampoule filling and sealing machine. Numerous pieces of equipment incorporate novel technology to meet changing industrial needs. Although this machine is more expensive, it can easily satisfy your requirements if you want to scale up the operation.

Reliable Supplier

Reliable Supplier- Picture Courtesy: Happy Rubin

With due diligence, you can determine the repute and reliability of the manufacturer. With searching and investigation, you can check if they have a suitable and relevant machine. Do they have quality certification and for how long they are conducting the business? Try to find feedback from current and past clients, as you evaluate other aspects of their businesses.

Conclusion

In short, efficiency, speed, versatility, sterility, and whatnot are achieved with the ampoule filling and sealing machine. It is a great invention that takes the business to the next level of success. This machine is acquired to boost the operational capacity by fulfilling both current and future needs. It is durable and easy-to-operate equipment that does not break down often. The "Ampoule Filling and Sealing Machine: The Complete FAQ Guide in 2025" post facilitates useful information when you go shopping for an industrial-scale machines. AIPAK ENGINEERING closes the gap between you and the equipment by offering the best-quality ampoule filling and sealing machine. We, provide a top-notch after-sale program to support you in every matter.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours