BFS Machine: The Complete FAQ Guide In 2025

Do you want to aseptically fill parenteral drugs? Then a BFS machine is the solution just for you. BFS machine is a revolutionary technology in the pharmaceutical and healthcare sectors. It is used for aseptic and sterile filling of bottles, vials, and ampoules.

BFS machine is an automated and efficient combination of machines, carrying out different jobs from creating containers to sealing them. It is an advanced manufacturing turnkey solution, producing different IV solutions in a continuous set of operations. There is no need for human supervision in this machine.

Are you interested in exploring new options for your production, or want to have a deep understanding of the BFS machine? We have detailed this blog to offer you inclusive insight into the BFS machine, its working operation, applications, types, and so much more.

1.Define BFS Machine

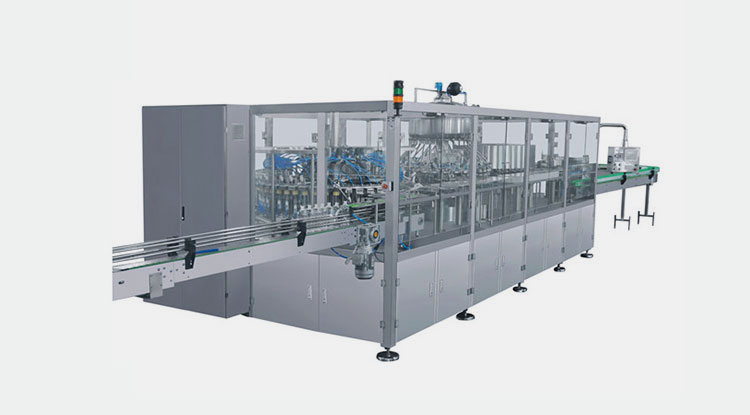

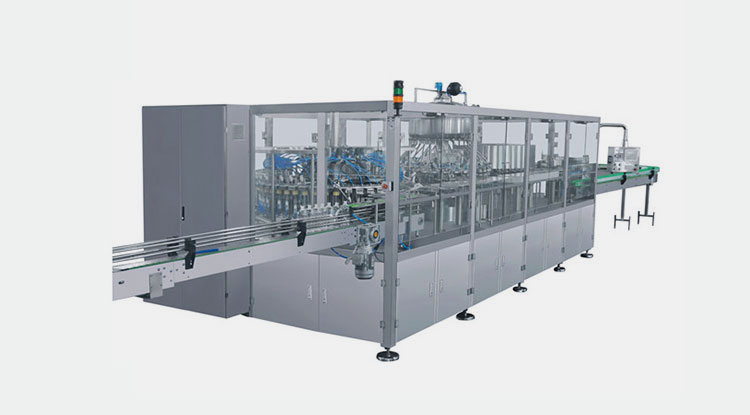

BFS Machine- Picture Courtesy: Brevetti Angela

The BFS machine is defined as a blow, fill, and seal machine. It is an automatic series of machines that manufacture sterile containers by molding or extrusion with thermoplastic granules. After creating, it packs pharmaceutical products and ultimately seals these containers in a continuous operation.

It combines different machines into one and performs its function continuously and it incorporates aseptic technology for sterile processing and to deliver safe products to the patients. It can create tailored shapes of bottles, ampoules, and vials. There is no presence of foreign particles and pyrogens in the BFS machine, therefore, this machine is recommended by drug regulatory authorities.

2.What is the History of the BFS Machine?

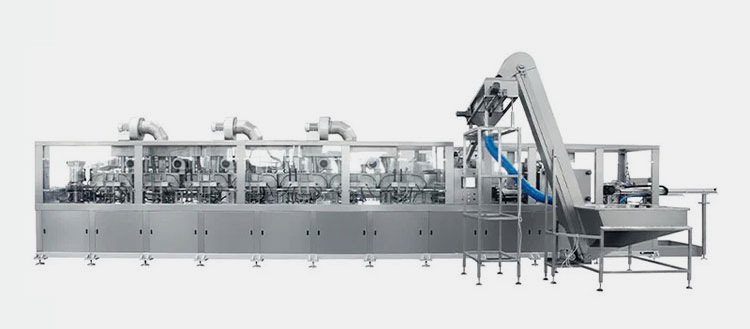

History of BFS Machine- Picture Courtesy: Shanghai Marya

BFS machine originated in Rommelag, Germany. In 1963, Gerhard Hansen filed a patent for the BFS process. In the early 1970s, the Bottelpack system of Rommelag was invented, in which the BFS process for making large-volume parenteral solutions was used.

BFS machine was well-established in the late 1980s in the pharmaceutical and healthcare sectors. The increasing demand for sterile packaging has led to the adoption of the BFS machine in many industries. Today, in addition to the pharmaceutical and healthcare sector, BFS machine is also seen in the food and beverage industry.

3.Enlist the Benefits of BFS Machine

BFS machine is an automated technology that brings simplicity, reliability, and cost-effectiveness to regular production lines. Some of the useful advantages of this handy machine are written below for your information.

Customization

Customization of BFS Machine- Picture Courtesy: Linkedin

The BFS machine can create customized container types and shapes according to the needs of production. It is versatile and flexible in terms of container creation as it can produce an infinite range of containers. In addition to this, it also has material flexibility and can process different materials without changing the molds.

Accuracy in Filling

Accuracy in Fill by BFS Machine- Picture Courtesy: VSUN

One of the major pros of the BFS machine is its fill accuracy. Traditional filling can have minute differences in the fill product volume. But this machine can dispense exact volumes of the products with no chance of error with its sterile filling machine. That is why the BFS machine is renowned in the pharmaceutical sector.

No Contamination

No Contamination by BFS Machine- Picture Courtesy: Brevetti Angela

BFS machine is a closed system blowing, forming, and continuously filling containers. There is no human involvement, thus there is no chance of microbial or foreign objects contamination by humans. It hygienically produces finished products and is regarded as one of the safest machines in the pharmaceutical sector.

Aseptic Filling

Aseptic Filling by BFS Machine- Picture Courtesy: LinkedIn

This type of filling is important in the pharmaceutical industry because it produces sterile products with no pyrogen presence. BFS machine is essential in this aspect, as it has integrated aseptic filling. The products produced by the BFS machine last longer and have longer expiration dates due to aseptic filling.

Scalability

Higher Scalability by BFS Machine- Picture Courtesy: Brevetti Angela

This machine has higher scalability as it can process both niche batches as well as large volume batches within a short time duration. Manufacturers highly prefer the BFS machine because of its scalability.

Small Footprint

Smaller Footprint of BFS Machine- Picture Courtesy: SteriMax

Traditional filling systems require separate and large machines for washing and sterilizing the bottles and other containers and require more space. However, the BFS machine has a smaller footprint because it blows, fills, and seals containers from plastic granules, thus there is no need for specialized washing and sterilization. It has a shorter logistic chain.

4.How to Classify BFS Machine?

There are numerous types of BFS machines depending on the equipment design, type of fill volume and working process. These machines also differ in their operation control as well. These types are discussed below:

According to Fill Volume Type

SVP (Small Volume Parenteral) BFS machine

Aipak Engineering SVP (Small Volume Parenteral) BFS machine

This machine is used for packing small volumes of parenteral drugs. SVP BFS machine fills the volumes of parenteral drugs in the range of about 0.1 ml to 20 ml. This machine can produce large numbers of containers, making it an excellent addition to the pharmaceutical and healthcare sector. It is scalable, fulfilling higher production demands.

LVP (Large Volume Parenteral) BFS machine

Aipak Engineering LVP (Large Volume Parenteral) BFS machine

This type of BFS machine can produce large-volume parenteral bottles. it can fill the products in the volume range of 0.2 ml to 1000 ml. It has a larger footprint and can produce a higher number of bottles per hour. It maintains sterility and aseptic conditions during blowing, filling, and sealing steps.

According to the Working Principle

Shuttling BFS Machine

Shuttling BFS Machine- Picture Courtesy: Shanghai Marya

This type of machine is also known as Parison cut machine. In the shuttling type of BFS machine, there are two separate locations for the container extrusion and filling process. The filling zone is adjacent to the container parison. A shuttling system is present in this type of BFS to transfer extruded plastic containers back and forth to the extrusion, filling, and sealing station. It has a modular design, therefore, it is easier to upgrade.

Rotary BFS Machine

Rotary BFS Machine- Picture Courtesy: Selpak

It is called a closed parison BFS machine because parisons are not exposed to the external environment. It has a rotary type of design and is the latest advancement in the BFS machines. The moulding, filling, and sealing stations are located at the same rotary table. This results in higher production speeds and a more compact design.

5.What are the Applications of BFS Machine?

BFS machine is continuously evolving, hence, its applications are increasing day by day. Some of the different applications of this important machine include:

Pharmaceutical Industry

Application of BFS Machine in Pharmaceutical Industry- Picture Courtesy: Rommelag

First and foremost, the BFS machine is vastly popular in the pharmaceutical industry. This industry is the primary application of the BFS machine. It is required in this industry because of its sterile and hygienic processing and packing. BFS machine fills different kinds of injectable drugs like eyedrops, antiseptics, antibiotics, and inhalation drugs (nebulizers).

Health care Industry

Application of BFS Machine in Health Care Industry- Picture Courtesy: World Pharma Today

This machine is also employed in the health care industry for filling different diagnostic reagents and wound care agents like saline, peroxide, etc. These agents are safely and hygienically processed and packed in large and small volume parenteral containers.

Biotechnology Industry

Applications of BFS Machine in the Biotechnology Industry- Picture Courtesy: Pharmaceutical Networking

Yes, one of the primary applications of the BFS machine is the biotechnology industry. This machine is used for filling different kinds of biologics, hormones, and vaccines in sterile bottles, vials, and ampoules. BFS machine is utilized for its sterility and precise dosing in the biotechnology industry.

Veterinary Industry

Applications of BFS Machine in the Veterinary Industry- Picture Courtesy: Pharmaceutical Networking

Yes, the BFS machine is crucial in the veterinary industry as it has integrated and advanced technology for safely blowing, filling, and sealing veterinary parenteral containers. Sterile and contamination-free manufacturing of pet care medication is essential for the health of pets and other animals.

Nutraceutical Industry

Applications of BFS Machine in the Nutraceutical Industry- Picture Courtesy: PharmaTech

It is the secondary application of the BFS machine. Certain nutraceutical products need barrier properties and sterile protection, hence BFS machine is used in the nutraceutical industry. This machine packs liquid vitamins and minerals, probiotics, and dietary supplements like amino acids and fats in liquid form.

Food and Beverage Industry

Applications of BFS Machine in the Food and Beverage Industry- Picture Courtesy: Rommelag

One of the latest innovations in the BFS machine is its application in the food and beverage industry. Single-serve juices and other beverages, baby formulas, and sauces are packed in the sterile packing by the BFS machine. This machine is important in extending the shelf-life of the food and beverage products.

6.Discuss the Working Principle of the BFS Machine.

A BFS machine is an efficient unit that has an interconnected set of machines, performing different manufacturing steps in a streamlined manner. It has five fundamental working steps, all occurring in a closed machine. The working principle of the BFS machine is discussed below:

Working Steps of BFS Machine- Picture Courtesy: Iven-pharma

Extrusion

Extrusion of Plastic Particles- Picture Courtesy: Brevetti Angela

At first plastic granules of desired materials are heated at a high temperature. Afterwards, the extrusion of molten granules is carried out to create a hollow soft plastic tube called a parison.

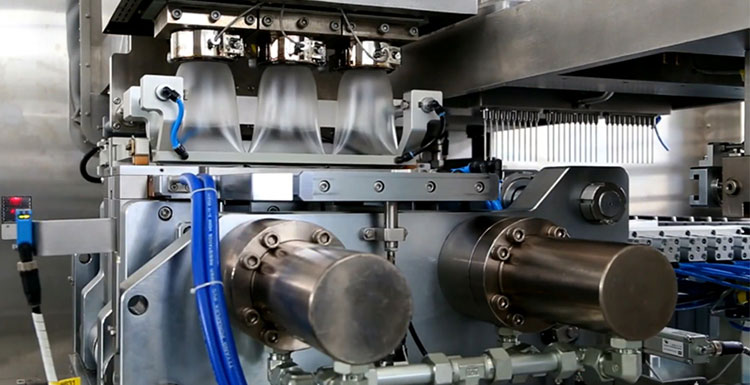

Moulding

Molding of Container- Picture Courtesy: Brevetti Angela

Then specially designed molds enclose over the parison. The sterile gas is introduced into molds to blow parison against the inner structure of molds. This step creates a container of the desired shape. Different gases are used for blowing and molding such as air, nitrogen, and inert gas. The vacuum formed in the mold cavity during the molding process allows for the sterile shaping step.

Filling

Filling of Container- Picture Courtesy: Brevetti Angela

Now the filling nozzles are fed inside the neck of the formed container to load different types of pharmaceutical products. at this stage, sterile gas is blown against the filling nozzles and the open end of the formed container to prevent the contamination risk.

Sealing

Sealing of Container- Picture Courtesy: Brevetti Angela

After filling of products, the next step is the sealing of containers which is executed by the sealing jaws. These jaws enclose over the top of the container to airtightly seal the top of the filled container. In the next step, the top seal end is cut to create the aesthetically pleasing look of the container.

Deflashing or Discharging

Discharging of Container- Picture Courtesy: Brevetti Angela

In the last step, the flash present in the molding halves is removed and the sealed containers are discharged from the BFS machine to the next labeling and packaging steps.

7.What are Materials Handled by the BFS Machine?

The BFS machine can handle wide-ranging materials, especially thermoplastics. These materials are used for blowing, filling, and sealing different containers. Let’s have insight into the world of materials processed by the BFS machine.

Polyethylene (PE)

PE BFS Containers- Picture Courtesy: Rommelag

There are two types of PE materials: low-density polyethylene and high-density polyethylene. LDPE is flexible and used in making small parenteral containers while HDPE is rigid and makes tough high-volume parenteral containers. These are known for their chemical resistance and moisture barrier.

Polypropylene (PP)

PP BFS Containers- Picture Courtesy: Shanghai Marya

It has more chemical resistance and a higher melting point than PE materials. This feature is essential when PP containers are autoclaved in the sterilization process.

Polyethylene Terephthalate (PET)

PET BFS Containers- Picture Courtesy: Brevetti Angela

It is less frequently used in the BFS machine, as it is a rigid material. PET provides an excellent barrier against atmospheric gases like oxygen and carbon dioxide.

Copolyester

Copolyester BFS Containers- Picture Courtesy: Brevetti Angela

It is popular in the BFS machine industry because of its clarity, strength, and good barrier properties. It is usually used for making containers that need visual scrutiny.

Biodegradable Plastics

Biodegradable Plastics BFS Container- Picture Courtesy: www.highfinegroup.com

With rising sustainability concerns, manufacturers have made a switch over to biodegradable plastic resins like Polylactic acids (PLA) for making sterile aseptic containers.

8.What Containers are Filled by the BFS Machine?

BFS machine is versatile in container filling. There are numerous different types of containers filled by the BFS machine including:

Vials

BFS Vials- Picture Courtesy: Brevetti Angela

These are small round containers but a small neck. Vials can be single and multi-dose. These containers are filled with vaccines, injectable parenteral medications, and ophthalmic solutions.

Ampoules

BFS Ampoules- Picture Courtesy: Brevetti Angela

These are small single-dose cylindrical containers with a narrow neck. These are used for holding various parenteral drugs

Prefilled Syringes

BFS Prefilled Syringes- Picture Courtesy: Brevetti Angela

These are the narrow cylindrical containers, containing pre-measured doses of medication and are used for self-administration. These are also convenient in the hospital settings, as they are already filled with medication.

Eye Drops Bottles

BFS Eye Drop Bottles- Picture Courtesy: Brevetti Angela

These are the small bottles, having a smaller dropper for administrating the measured dose of an ophthalmic solution to the eyes.

Bottles

BFS Bottle- Picture Courtesy: Brevetti Angela

These are square or cylindrical containers, having small and medium-sized volumes. These bottles are used for supplying vaccines, biologics, hormones and other parenteral drugs.

9.What is the Regulatory Certification of BFS Machine?

The regulatory certification of the BFS machine depends upon the country in which the BFS machine is used and the products formed by this machine. Various regulatory certifications of the BFS machine are:

CE Marking

CE Marking

This is a mandatory certification for the BFS machine, operated in the European Union countries. This machine must comply with machine directives to acquire CE marking.

FDA Approval

FDA Approved

The BFS machine working in the United States must obtain FDA approval to ensure the quality and reliability of the manufactured products.

ISO Certification

ISO Certification

It is must must-have certification for machines all over the world. This certification tells the pharmaceutical and healthcare sectors that manufacturers and production lines of the BFS machine have implemented quality control measures to fulfil safety requirements.

GMP Certification

GMP Certification

It is a good manufacturing practice standard. The BFS machine must adhere to GMP certification to ascertain that this machine carries out all necessary steps to prevent contamination and ensures quality at every step of manufacturing.

Pharmacopeial Compliance

US Pharmacopeia- Picture Courtesy: usp.jobs

This machine must follow different pharmacopeial regulations like US Pharmacopeia (USP), European Pharmacopoeia (Ph. Eur.), and Japanese Pharmacopoeia (JP). These pharmacopeial regulations offer essential guidelines to assure sterility and quality of manufacturing.

10.How Does BFS Machine Maintain Sterility?

Sterility is an important aspect of the BFS machine because this machine processes containers and applications that require sterile conditions. There are different ways by which the BFS machine maintains sterility such as:

Aspectic Environment

Aspectic Environment of BFS Machine- Picture Courtesy: Brevetti Angela

The fundamental principle of sterility in the BFS machine is the aseptic environment. The airborne microbial contamination is avoided by generating the controlled zone within the production plant. HEPA filters eliminate airborne microbial from the air present in the filling and sealing areas.

Moreover, with positive air pressure, unfiltered air cannot enter the aseptic environment. The workforce supervising the BFS machine always wears protective gloves and overalls.

Sterilization Procedures

Sterilization Procedures of BFS Machine- Picture Courtesy: Brevetti Angela

The parts of the machines that come in contact with the containers are sterilized using different techniques like steam sterilization, UV radiation, gamma radiation, E-beam sterilization, vaporized hydrogen peroxide sterilization, etc. Furthermore, the BFS machine is also disinfected by peracetic acid.

Filling Solution Sterilization

Filling Solution Sterilization- Picture Courtesy: VSUN

In some BFS machines, the pharmaceutical and medical fill products are also sterilised using filtration, irradiation and heat. These solutions undergo different sterilization processes to remove microbes.

Barrier Systems

Barrier System- Picture Courtesy: Syntegon

BFS machine also uses single-use molds, created from sterile materials, removing the need to clean and wash molds for blowing. This machine also incorporates advanced barrier systems like laminar airflow and isolator technology to create a physical separation between the machine and the working environment.

11.What are the Challenges and Solutions of BFS Machine?

The challenges of the BFS machine are important in industries, where sterility and accuracy have immense worth. Addressing these challenges brings much-needed success to businesses. These challenges are resolved by implementing the latest technology, and quality control measures and following strict procedures. The challenges and solutions of BFS machine are:

High Purchase Cost

High Purchase Cost of BFS Machine- Picture Courtesy: Pharmaceutical Networking

BFS machine needs a huge initial investment. This cost does not only include buying equipment but also includes the infrastructure needed to set up the machine.

Solution

Plan by analyzing the ROI. Before investment, this analysis will help you justify the cost of machines and infrastructure by calculating profit margins and production efficiency.

Complicated Operation and Maintenance

Complicated Maintenance- Picture Courtesy: Brevetti Angela

Extensive training and operational skills are needed to operate and maintain the BFS machine. It has a complicated mode of operation, consequently requiring specialized knowledge to operate. Moreover, the BFS machine requires regular maintenance for its aseptic processing.

Solution

By implementing comprehensive and wide-ranging training programs you can improve the skill set of the workforce. Also, manufacturers of the BFS machine offer different training and support programs for maintaining and operating this complicated machine.

Material Restrictions

Material Restriction in BFS Machine- Picture Courtesy: VSUN Tech

Although the BFS machine is flexible in container packaging, there are limitations on materials in the BFS machine, impacting product compatibility.

Solution

Evolving material science innovates new materials that are easily processed in the BFS machine. Improvement in resin formulation has allowed the BFS machine to handle a wide range of materials. Also, collaborations with the material formulator will create new materials that fulfil the processing needs of the BFS machine.

12.What are the Innovations in BFS Machine?

Innovation in BFS Machine- Picture Courtesy: Iven-pharma

BFS machine is leading pharmaceutical sterile processing due to its ability to combine several processes and machines into a single machine. With the passing years, several innovations have been made into the BFS machine.

Advanced sterilization techniques are introduced in the BFS machine to thoroughly sterilize the whole manufacturing process. It ascertains the better sterility rates. The construction of the BFS machine is modular and scalable allowing pharmaceutical companies to upscale and downscale their production processes.

Real-time quality control sensors and vision cameras have been added to the BFS machine to examine real-time process changes and to measure critical parameters like pressure, temperature, filling volume, etc. Moreover, robotics technology has been implemented to innovate the BFS machine. This allows the machine to easily manipulate and process the containers without the need for human supervision.

To better track and trace the containers throughout the operation, data management systems have been incorporated into the BFS machine. Furthermore, with the Internet of Things, the BFS machine can do predictive maintenance that reduces downtime.

Conclusion

A BFS machine is a collection of different machines, performing specific functions to carry out continuous operations. It is an innovation in the pharmaceutical sector that blows, fills, and seals different containers with speediness. It has a sterile process with no chance of contamination due to little human involvement. The containers formed and filled by the BFS machine are free of particulates. Products have a longer shelf-life with this technology. It is easier to supply and store containers with a BFS machine. Let’s wrap up this FAQ guide. For more queries and purchasing, you can contact Aipak Engineering.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours