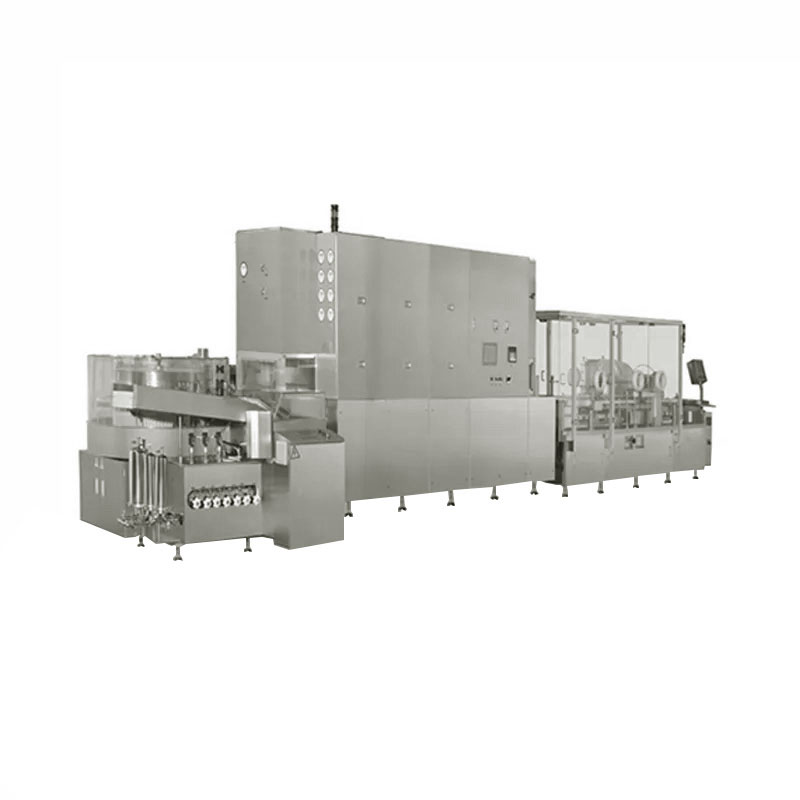

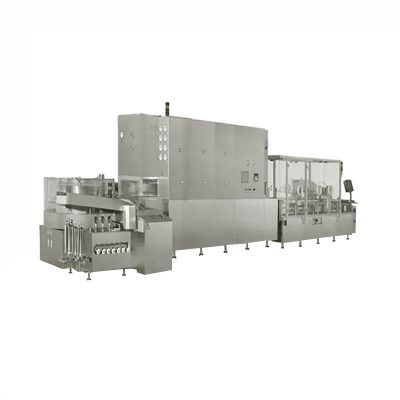

High Quality/Output/Precise 1-20ml Ampoule Filling Line

AIPAK Engineering 1-20ml ampoule filling Line is composed of ultrasonic bottle washing machine, dryer sterilizer and ampoule filling and sealing machine. It can complete spraying water, ultrasonic cleaning, air & water flushing of inner and outer wall of ampoule bottle, preheating, drying and sterilization, heat source removing, cooling, (nitrogen pre-filling), filling, (nitrogen post-filling), ampoule sealing and other complex functions, realizing automatic production of the whole process. Each machine can be used separately or in linkage line. The whole line is mainly used for ampoule injections filling in pharmaceutical factories and the general type can also be used for antibiotic vial injection filling or powder filling.

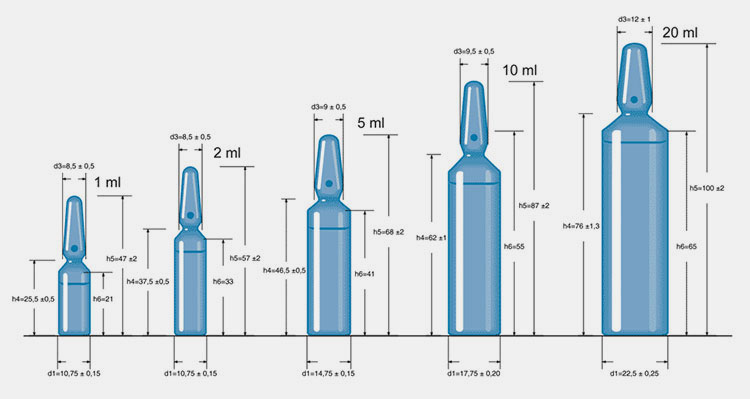

Ampoule example:

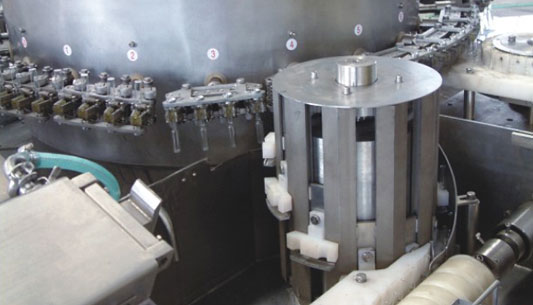

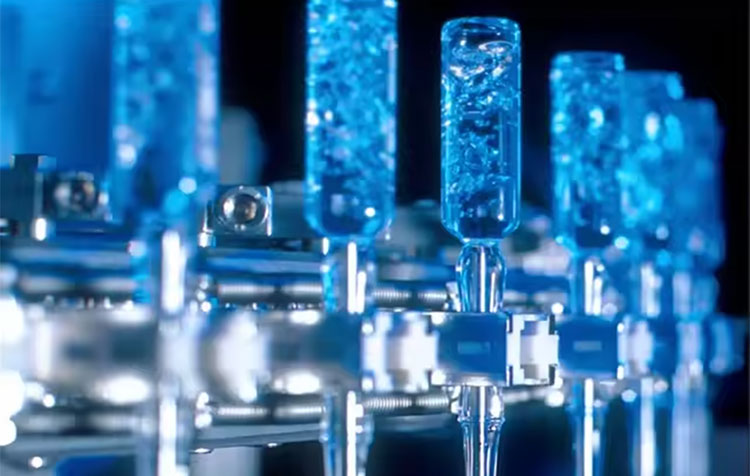

AKCA series vertical ultrasonic washing machine

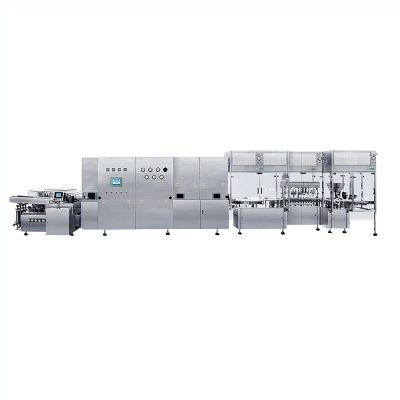

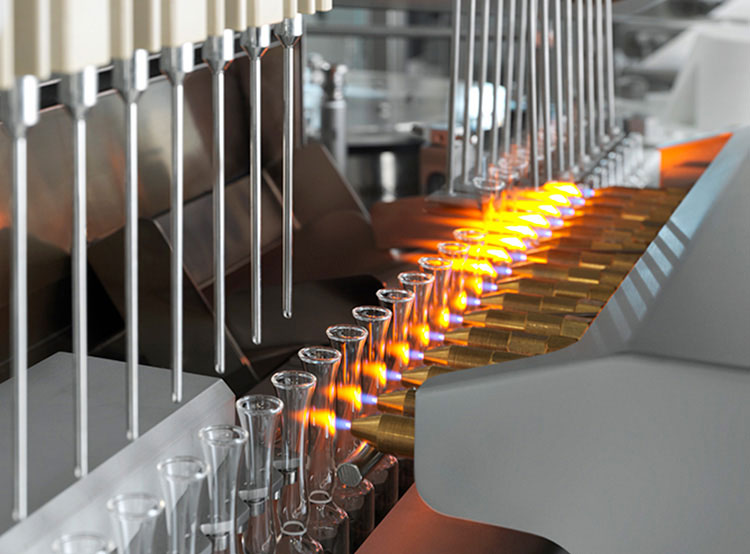

AKDH series hot air circulation sterilization tunnel

This machine is mainly used for drying, sterilization and pyrogen removal of small glass bottles such as ampoules, vial bottles and oral liquid bottles in pharmaceutical industry.

It can automatically completes the whole production process from bottle feeding, preheating, drying and sterilization, cooling to bottle bottle discharging. The laminar flow principle and hot air high speed disinfection technology can make the container reach the national cleanliness level 3 standard (American industrial standard level 100) in the sealed tunnel. It is the most popular drying sterilization equipment with the best sterilization effect in the world. Its heat distribution is uniform and the effect of pyrogen removal is good.

It can be used not only by single machine, but also by connecting with the bottle washer in front and the filling machine in back.

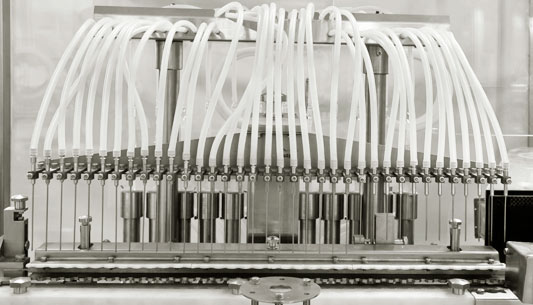

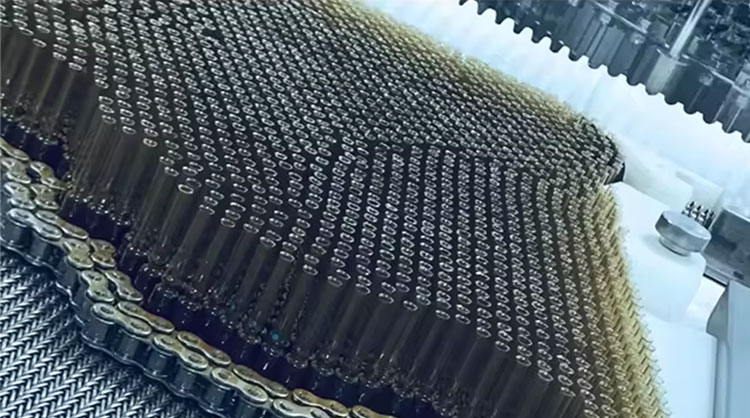

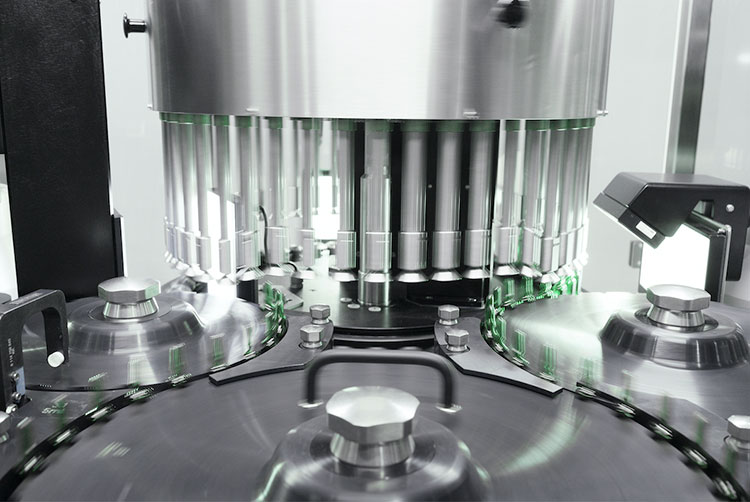

AKA series ampoule filling and sealing machine

1-20ml Ampoule filling Line Features:

1.The ampoule filling sealing machine consists of this series vertical untrasonic washing machine,this series hot air circulation sterilization tunnel,filling and sealing machine.The ampoule filling machine can be used in combination or in a single machine.The ampoule filling sealing machine an complete water spray filling,untrasonic cleaning and flushing(internal and external),CA flushing(internal and external),preheating,drying and sterilization to remove heat source,cooling,before and after netrogen,sealing after preheating,sealing and other processes.

2.This ampoule filling sealing machine can meet the size range from 1-20ml ampoule of washing,drying and sterilizing to remove heat source,filling and sealing requirements of the production process.

1-20ml Ampoule filling Line Technical Specification:

| Product model | AFL-6 | AFL-8 | AFL-10 | AFL-12 | AFL-16 |

| Adaptive Specifications (ml) | 1-20ml (ampoule) | 1-10ml (ampoule) | |||

| Production capacity (pcs/h) | 6000-16000 | 8000-21000 | 10000-24000 | 12000-30000 | 16000- 36000 |

| Number of filling pins | 6 | 8 | 10 | 12 | 16 |

| Power source | 380V 50Hz | ||||

| Electrical capacity (kW) | 78 | 78 | 80 | 90 | 90 |

| Total weight (kg) | 8900 | 8900 | 9400 | 9700 | 10100 |

| Overall dimensions (mm) | 9100x2200x2450 | 9100x2200x2450 | 9260x2200x2450 | 9910x2200x2450 | 10042x2200x2450 |

1-20ml Ampoule filling Line Video

The Buyer's Guide

Ampoule Filling Line: The Complete FAQ Guide In 2025

Why ampoules are so special in the medical sector?

This is the question that knocks everyone’s mind. Isn’t it? A cost-effective and precise concentration at individual servings makes it popular among all of you.

Picture courtesy: Facet LLC

How they are prepared? Nevertheless, the preparation ampoule is passed by a series of different equipment known as the ampoule filling line. Today, we have designed a blog related to ampoule filling line.

Before purchasing or adding any one of the units, we would like to go through this blog to avail useful points that you shouldn’t miss. Come on and read this informative article.

1.What is an ampoule filling line?

AIPAK ENGINEERING Ampoule filling line

Nevertheless, whenever you’re dealing with glass, the manufacturing process meets numerous challenges.

An ampoule filling line is the solution for washing, sterilizing, filling, and sealing of ampoules in one set of equipment with such a closed monitoring system.

It is not wrong to say that it is a tremendous set of machines for generating a high output for ampoule production and filling under gentle handling and hygienic processing including various stations i.e. ultrasonic vibration, fire unit, etc that ensure you with a flexible upstream for your entire production unit.

2.Why ampoule filling line is significant?

Ampoules- Picture Courtesy: Larimide

This is a sophisticated addition to medicines and healthcare sectors that effectively brings filling and sealing tasks without any risk of errors! There are various advantages when you’re installing an ampoule filling line; some of the important benefits are discussed below:

Various Automation

Greater automation

You can enjoy the ampoule filling line with various automation either you can install manual operating machines or fully automatic ones, but the following set of units can be facilitated to you such as washing, sterilizing, drying, filling, etc. Not only you can avail accurate filling but also perfect sterilization.

Inert Gas Flushing

Inert gas- picture courtesy: CPHI online

To enhance more stability before sealing the ampoules, an ampoule filling line is featured with inert gas flushing property which is used to flush out oxygen and replace it with inert gas such as nitrogen.

However, it provides more stability to your product against the progression of unwanted microbes or contamination. Remember, these gases are inert, which means it has no ability to react or interact with your product hence they can be kept stable for a long time.

Fill Volume Precision

Filling volume- Picture courtesy:IMA group

You can fill your ampoules set with an exact volume every time as mentioned in the labeling. An ampoule filling line promises to offer accurate filling of dose in each production batch. This is all due to the highly computerize and systemic operating parameters of each machine interconnected in the ampoule filling line.

No Training is Needed!

Extremely user-friendly- picture courtesy: PCNE

You will be glad to know that an ampoule filling line is an advanced technology that is easy to use and requires no training. Once you understand the components and main setup points., you can operate the whole system alone.

This is all because of the features of a touch screen system that enables you to operate the procedure by easy options available on the screen. It includes, the run rate, amount of drug per ampoule, speed of the conveyor, flame intensity etc.

Inspection Unit

Tremendous monitoring- picture courtesy: Carlroth

The ampoule filling line is adjusted with high-technologies inspection cameras followed by specialized sensors that help you through the working procedure to ensure each and every step of the process is well-controlled and just right without any risk of flaws.

Saves Your Money

Cost-effective- picture courtesy:DGTcom

Of course, if you have a system with super-efficient sensors, and high automation that follows each step in a seamless way and without any hurdle, then why would you look for extra technicians or operators? Also, why would you waste your time in manual or implementing the conventional method of filling? this is a significant line that helps in reducing entire labor costs and boosting your productivity.

3.Where do you use the ampoule filling line?

The uses of ampoule filling lines are unlimited, the following setup is mainly used in a broad industrial sector for the manufacturing of various related liquid solutions that are dispensed in a single serving small unit dose. Let’s peek at the below discussion to explore the uses I am talking about!

Pharmaceutical Industry

Uses of ampoule filling line in pharma- Picture Courtesy: European Pharmaceutical

When you are vaccinated, using antibiotics, injecting painkillers, or other related substances, you must have noticed small ampoules made up of glass with neat and clean solutions inside. This is where an ampoule filling line is used. You guessed right, in the pharmaceutical industry, an ampoule filling line has a specialized role in dealing filling and sealing of sterile preparations just like a computerized pharmacist.

Diagnostic Solutions Manufacturer

Diagnostic Solutions- Picture Courtesy: Qlick

Various diagnostic reagents, stains, and associated products are dispensed in ampoules. The diagnostic solution manufacturing sector requires an ampule filling line to be installed to ensure the preparation free from impurities to bring promising lab outcomes.

Biotechnology Industry

Biotech ampoules- Picture courtesy: AlmedicaAG

This industry mainly deals with the preparation of substances like proteins, recombinant nuclear materials, vaccinations, monoclonal antibodies, serums, gene therapies, cell culture, plasma, etc, and saved them in ampoules that are utilized upon certain series of processing. Therefore, an ampoule filling line is crucial to be added in certain sectors to bring accurate dosing of valuable fill.

Cosmetic Industry

Cosmetic ampoules- Picture Courtesy: Medicura

You might be thinking of the role of the ampoule filling line in cosmetic preparation, but the following machine indeed has a significant role in the preparation of cosmetic products like skin serums, oils, and other potent ingredients in ampoules for intact freshness and potency.

Chemical Industry

Sulfuric acid- Picture courtesy: Fisher scientist

This is very challenging to handle chemicals manually, but an ampoule filling line is mainly used in this sector to deal with harsh chemicals safely and accurately. You can store chemicals like organic, inorganic, and neutral compounds in an ampoule to keep them saved for a longer time.

Nutraceutical Industry

Antiaging nutraceutical solution- Picture Courtesy: Bothcos

Thanks to the ampoule filling line that ensures the filling and sealing of various probiotics, nutritional supplements, trace elements, protein, and related dietary supplements accurately and safely in ampoules to facilitate the secure packaging that you deserve.

Veterinary Industry

Vet industry- Picture Courtesy: Dr. Andy Roak

In the veterinary industry, an ampoule filling line is required for safe and sterile preparation and sealing of products related to your loved pet such as antibiotics, painkillers, antiallergy, and other liquid preparations.

4.What are the units of the ampoule filling line?

The composition of the ampoule filling line is mentioned below:

Ampoule washing Machine

AIPAK Engineering ampoule washing machine

The ampoule washing machine is the first unit of the filling line that is mainly used to make and get cleaned ampoules prior to the filling process. The special aim behind this machine is to provide a way for washing ampoules offered by minimal contact with parts of the machine

It is mainly done by picking ampoules using mechanical grippers that support gentle inversion of ampoules and ensure complete washing in an inverted position.

There are two basic types of ampoule washing units.

Deep ampoule washing unit

One is an ultrasonic washing machine that utilizes a high-frequency vibration technique that mainly helps you in the removal of sticky debris or stains over the surface of the ampoule. The ultrasonic vibration hits water molecules in and out surface of the ampoules and knocks out the sticky materials or any unwanted foreign substances that can affect the quality of the ampoules.

Moreover, the equipment inherits the higher strength sound which is helpful in the elimination of microbes just by sound waves.

Besides this., the rotary ampoule washing machine utilized a rotary carousel with intense water flow subjected to each ampoule presented in the washing unit.

Once they're washed, an out-feed worm unit allows the neat and sterile ampoule release.

Hot Air Sterilization Tunnel

AIPAK ENGINEERING hot air circulation sterilization tunnel

A hot air sterilization tunnel is a new technology which is also known as a depyrogenation tunnel as it is helpful in the eradication of microbial contamination effectively.

This tunnel utilizes dry sterilizers which can be referred to as oven-type heat coils that radiate high temperatures from the bottom of the machine. The hot air raises the temperature till the required times for the sterilization process.

The hot air is circulated uniformly and maintains the temperature required to remove or sterilize the ampoule fully. The cooling tunnel is also there to cool the ampoules, this technique is often not available in old or conventional tunnels. In the sterilization tunnel, the commonly used temperature is 170 °C (340 F) for one hour or 160 °C (320 F) maintained for 2 hours, and 150 °C (300 F) for 2.5 hours. In the cooling phase, the airtight insulated gasket inflates and allows pre-determined sterilization time.

Ampoule Filling and Sealing Machine

AIPAK ENGINEERING ampoule filling and sealing machine

This is the significant part of the ampoule filling line playing an important role in the processing of formulations in the manufacturing industries worldwide especially in the pharmaceutical industries.

The biological equipment manufacturers take care of your needs that’s why this machine is designed to meet all requirements for liquids as well as other formulations in the ampoule.

The wire mesh once received sterilized ampoules that are mainly filled and neck sealed by this unit. The machine offers fast production to you with pre gassing and post gassing feature for every ampoule.

Due to high production, you make the feat of high goal every hour. Moreover, this equipment gives well well-controlled fire or flame flow with a cooling system to avoid overheating the machine ultimately making it long long-lasting investment for you.

Moreover, this is very easy to integrate with other machinery hence you can meet the needs of production demand up to a great level.

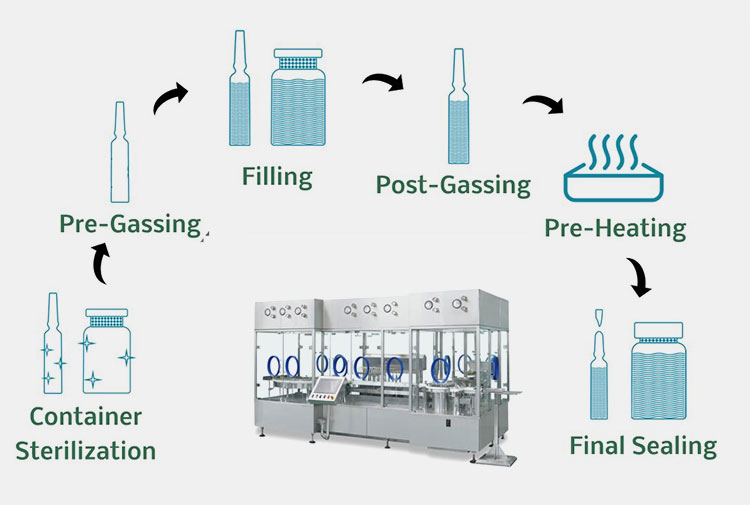

5.How ampoule filling line works?

The working steps of ampoule filling line

The production of ampoule filling is based on the following working steps.

| Container Washing and Sterilization | Glass ampoules for injectable products are normally cleaned and sterilized first by using the ampoule washing machine and a sterilization tunnel to dehydrogenate them completely.

The presence of endotoxin or other microbes can be killed completely once passed through these two stages ensuring that ampoules are now pyrogen free. The reference temperature is mainly 250ºC where E.coli and endotoxins deactivate completely |

| Pre-gassing | To clean the ampoule surface completely, it is first pre-gassed by using an inert gas purging. |

| Filling | The filling station is meant to accurately fill the ampoule with an injectable solution with the help of nozzles and pumps. During the procedure, the sensors are alerted to control the irregularities during the procedure. |

| Post gassing | Your products in ampoules are now again purged with inert gas to ensure the entire process is highly sterilized and well-controlled. |

| Pre-Heating | Ampoule necks are now subjected to the pre-heating unit where flame melt the glass surface in order to acquire the correct shape of the ampoule. |

| Final Sealing | Under high temperature or fire softens the layer of the glass with simulatenous sealing to form tamper evident closing. The presence of brush fire allows neat and finished surrounding of the ampoule surface. |

6.What Sealing Methods Used to Seal Ampoules in Ampoule Filling Line?

There are two sealing methods for ampoules in the ampoule filling line. These are:

Pull Seal Method

Pull Seal Method- Picture Courtesy: Sciencemadness.org

In this sealing method, the glass of the ampoule is melted in the middle. A thin amount of glass is stretched to create a seal. The pull seal method results in irregular and poor sealing of ampoules, putting users at risk of injury. There are variations in ampoule height with this method.

Tip Seal Method

Tip Seal Method- Picture Courtesy: Adinath International

It is also called the bead seal method. The glass of the ampoule is melted on the top, creating a round and smooth seal. The seal with this method has an elegant appearance, hence there is no risk of operator injury. Consistent height ampoules are produced by the tip seal method.

7.What are the parts machines involved in the ampoule filling line?

The parts of machines used in the ampoule filling line are discussed below:

AIPAK ENGINEERING parts of the ampoule washing machine

| Ampoule Infeed Track | Glass ampoules are always prone to scratches or damage during handling. This part of the machine is specially made to ensure uniform and gentle loading of the ampoules feeding in the machine. A chain just behind the infeed is meant to allow flexible movement and maintain the space among them hence jamming could be avoided. |

| Ampoule Washing Track | A series of ampoules moves from one phase to another phase via a conveyor system known as an ampoule washing track which assures that the procedure is taken place progressively correctly and washing steps (pre-washing, rinsing, pose washing) and rinsing are done smoothly. |

| Ultrasonic Tank for Impurities Removal | Ultrasonic washer generates small and tiny bubbles that gently that ensure disposing of the impurities surrounding the ampoule. |

| Compressed Air Blower Tank | The ampoules once they’re washed are subjected to the blower that uses high pressure to clear water particles around them and make them ready for further sterilization phase |

| Recycled Water Flushing Unit | The used water is cleaned and filtered again and recycled in the washing procedure which minimizes the extra water wastage during the processing and helps in the conservation of natural sources. |

| Control Panel | Its main control panel is based on the touch screen interface which is composed of essential keys and hooked to physical switches and buttons which helps in fast, safe, and efficient processing.

Moreover, you can be notified about the working status by the control panel showing on a monitor. |

| Electric Cabinet | This is indeed a critical and well-protected zone that is composed of circuits and electrical components sophisticatedly fixed inside the electric cabinet ensuring the user’s safety and protection against electrical hazards. |

| Supporter | The entire framework of the washing unit is mainly based on the four supporting units which negate the generation of vibration during work, unwanted noise, and firm fixation in your unit. |

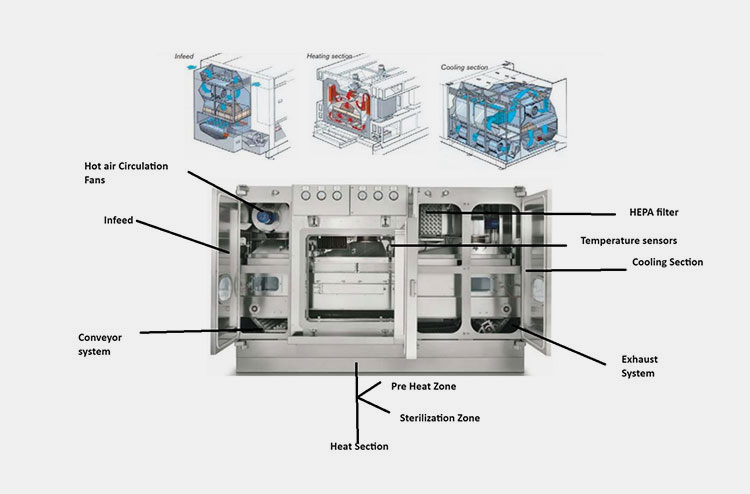

Hot Air Circulation Sterilization Tunnel

Hot air circulation sterilization tunnel

| Infeed | This is the gateway allowing ampoules to be entered inside the tunnel by the help of a conveyor which passes through the washing section towards the sterilization phase. |

| Hot air Circulation Fans | For effective circulation of warm and heated air, these fans are playing a significant role in the distribution of hot air particles in each corner of the tunnel. This is an excellent way to attain a uniform temperature inside and bring fruitful eradication of unwanted material inside and outside the ampoules. |

| Conveyor System | This is designed inside the tunnel followed by its entire length. The purpose of the conveyor system is to provide set of ampoules into each zone respectively and save your time. |

| Heating Section | This is the second section which is mainly divided into two zones, a pre-heat zone and sterilization zone to provide extensive heat into each ampoule. The difference between these two zones is the temperature which is higher in the sterilization zone than pre-heat that is typically above 320 to 350 degrees centigrade. |

| HEPA Filters | HEPA filter which is known as a High-Efficiency Particulate Air filter mainly used in every sterilization plant to ensure the inside environment is free from contaminated particles else it traps and maintain the sterile condition in the entire working process. |

| Temperature Sensors and Controllers | The inside tunnel is mainly set with various sensors and controllers that help you in the sensing and regulate the temperature. |

| Cooling Zone | This is the third zone where the temperature drops down gently in order to make the ampoule safe to touch and protect it against thermal shock. |

| Exhaust System | The generation of heat inside the tunnel is being emit out by the help of exhaust systems which make equipment well-controlled and preventive against heating up. |

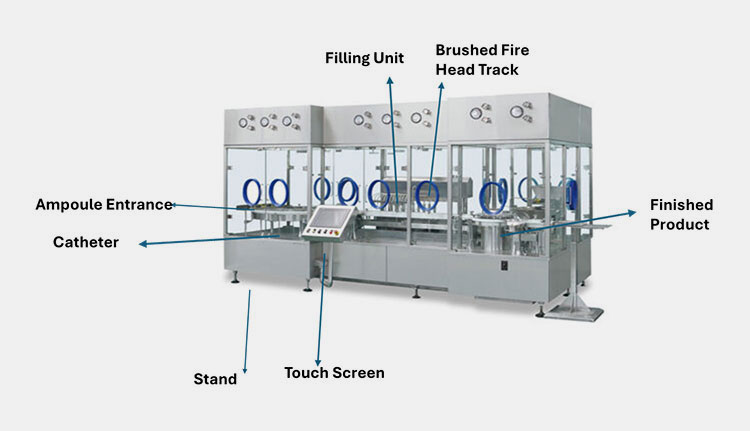

Ampoule Filling And Sealing Machine

Parts of AIPAK ENGINEERING ampoule filling and sealing machine

| Ampoule Entrance | In this machine, automatic or manual loading of ampoules takes place and the conveyor is responsible for transporting them towards the filling station. |

| Filling unit | This is the zone where ampoules are subjected to filling and are mainly composed of the catheter, and series of the pump where circulation of the solution takes place. |

| Catheter | A catheter is a delicate and needle-like tool that is mainly used to introduce the solution to be dispensed in the ampoule. The purpose of using a catheter is to fill your product with the precise volume of the drug and without causing it to waste during the filling process. |

| Brushed Fire Head Track | If you observe a video on our page, you will notice some burner radiating flame. These are meant to seal the ampoules hermetically. The burner produces fire that melts the surface or neck of the ampoule and the molten state forms the proper sealing shape of the ampoule. Moreover, the control regulators assess the positioning and temperature of the burners. |

| Finished Product | Once the ampoules are sealed, the gentle movement of the conveyor allows them to transfer out of the machine and makes its temperature lower. The finished product is collected outside the machine and sent for further packaging processes. |

8.How to classify ampoule filling line?

Ampoule filling line is classified into two main types depending upon the level of automation. These types are discussed below:

Manual Ampoule Filling Line

Manual Ampoule Filling Line- Picture Courtesy: Adelphi

It is a type of system in which the filling and sealing of ampoules occurs with minimal automation. Although this instrumentation is not so speedy and efficient, it is still a cost-effective solution for small businesses. Operators have to carry out all the processes like cleaning, loading ampoules, filling, sealing, and labeling. It is a hand-operated device that fills the solutions inside the ampoules.

Automatic Ampoule Filling Line

Automatic Ampoule Filling Line- Picture Courtesy: IVEN pharmatech

It has the highest level of automation, where the ampoule filling line is concerned. Every function from loading to ampoule labeling is carried out autonomously by the ampoule filling line. It is speedy and efficient, completing its tasks with little to no human involvement. Moreover, it has unparalleled consistency and accuracy. There is no chance of human error, so it does not impact the dose accuracy and ampoule quality.

9.How to troubleshoot the basic problems of the ampoule filling line?

Basic problems significantly reduce the work efficiency of the ampoule filling line. So, these problems should be identified and resolved with a systematic approach. For more uptime, follow these tips to troubleshoot the basic problems of the ampoule filling line.

Fill Inaccuracy

| Image | Cause | Troubleshooting |

Picture Courtesy: Nimesh Thakar Youtube Channel |

Defects in the pump or filling device

The presence of air bubbles in the fill solution Variation in fill solution viscosity |

Check and ensure the correct working order of the filling devices

Degass the fill solution before filling. Check and adjust the fill solution formulation and temperature to ensure consistent viscosity

|

Ampoule Breakage

| Image | Cause | Troubleshooting |

Picture Courtesy: Electron Microscopy Sciences |

Ampoules are not handled and positioned properly

High forces during sealing Ampoules are of poor quality |

Gently handle ampoules and position them accurately in the filling line.

Check and verify that the sealing instrumentation is working properly. Check the defects in the ampoules before filling and ensure they are of high quality. |

Ampoules are not Sealed Properly

| Image | Cause | Troubleshooting |

|

The sealing settings are not correct.

Defective sealing instrumentation. Improper cooling time after sealing. |

Review and reset sealing settings of temperature, pressure, and dwell time.

Replace the defective sealing instrumentation. Increase the cooling time to ensure a smooth sealing process. |

Contamination in Ampoules

| Image | Cause | Troubleshooting |

Picture Courtesy: Adinath International |

Ampoules and filling equipment are not washed and sterilized properly.

Contamination from the environment. Cross-contamination from the previously processed batch. |

Verify every step in the sterilization process of ampoules and filling equipment is followed properly.

Carry out the filling and sealing in the clean room meeting sanitation standards. Properly clean the machine between batches. |

10.What should know when designing an ampoule filling line?

For all businesses, the ampoule filling line is nevertheless a fruitful investment that brings a number of benefits. However, selecting and planning exactly what you need shouldn't be neglected.

If your objective to gain high profit revenue and patient compliance, you will need to understand the following strategies.

The nature of product

Animal treatment suspension- Picture Courtesy: MSD Animal Health

The nature of dosage form or products dictates the type of machine you need., for powdery substances the type of fillers required for drug dispensing, similarly for solvent products, what circulatory unit should be fitted within the machine, how to combat clogging, or type of system required to measure and fills suspension type product. Therefore you must understand the characteristics prior to opt for an ampoule filling line.

What ampoule size you are using?

Ampoule sizes- Picture Courtesy:AO+ Ampoule Opener

Typically ampoule size ranges from 10 to 20ml but in some cases, you can find more than the mentioned one. For example 25ml, or 50ml.

The machine must be influenced by your needs and capable of configuring the settings to deal the various ampoule size efficiently. For example, cosmetic ampoules are comparatively larger than pharmaceuticals, similarly vet ampoules are also available in larger sizes. Therefore you machine must be the right selection for such demands.

What Production Capacity Will You Need?

Ampoule production Capacity

Naturally, assessment of your production capacities would directly shapes the needs and expectations of your demands for example number of ampoules per minute or hour, however these factors reflect the required condition you should be achieved from a new machine.

Automation of Ampoules filling line

Automation of ampoule filling line- Picture Courtesy: IVEN

By knowing your demands, your vendor can guide you on whether you should select a manual semi automatic or automatic ampoule filling line, for newbies, a manual or semi automatic lines are far better. Once you are growing, you can definitely upgrade the profile by adding advanced and automatic machinery because they are more expensive and require advanced integration.

Is Integration Required With Other Units?

Integration of ampoule filling line- Picture Courtesy: Syntegon

This is well known that your production line may required with integration of other machines, that your supplier may suggest adding extra things like a conveyor, capping or unscrambled machine etc so you must have extra space to upgrade your production space for adding new units easily.

Conclusion

Hopefully, you have found this blog really interesting! In processing ampoule formation till the final finished product, the ampoule filling line promises that your solution is entirely safe and prepared under strict hygienic protocols. Are you interested in an ampoule filling line? Why not considering AIPAK ENGINEERING for better ampoule filling and sealing machinery- this is what we work for you. Our high-tech machines and individual solutions for ampoule filling lines and the relevant machine help medical and various industries across the world to improve packaging quality in an economical way. Please message us now and communicate with our team.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

1-20ml Ampoule Filling Line Related Products